Method for controlling organic waste gas

A technology of organic waste gas and racks, which is applied in the direction of separation methods, chemical instruments and methods, air quality improvement, etc., and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further detailed explanation through specific implementation mode below:

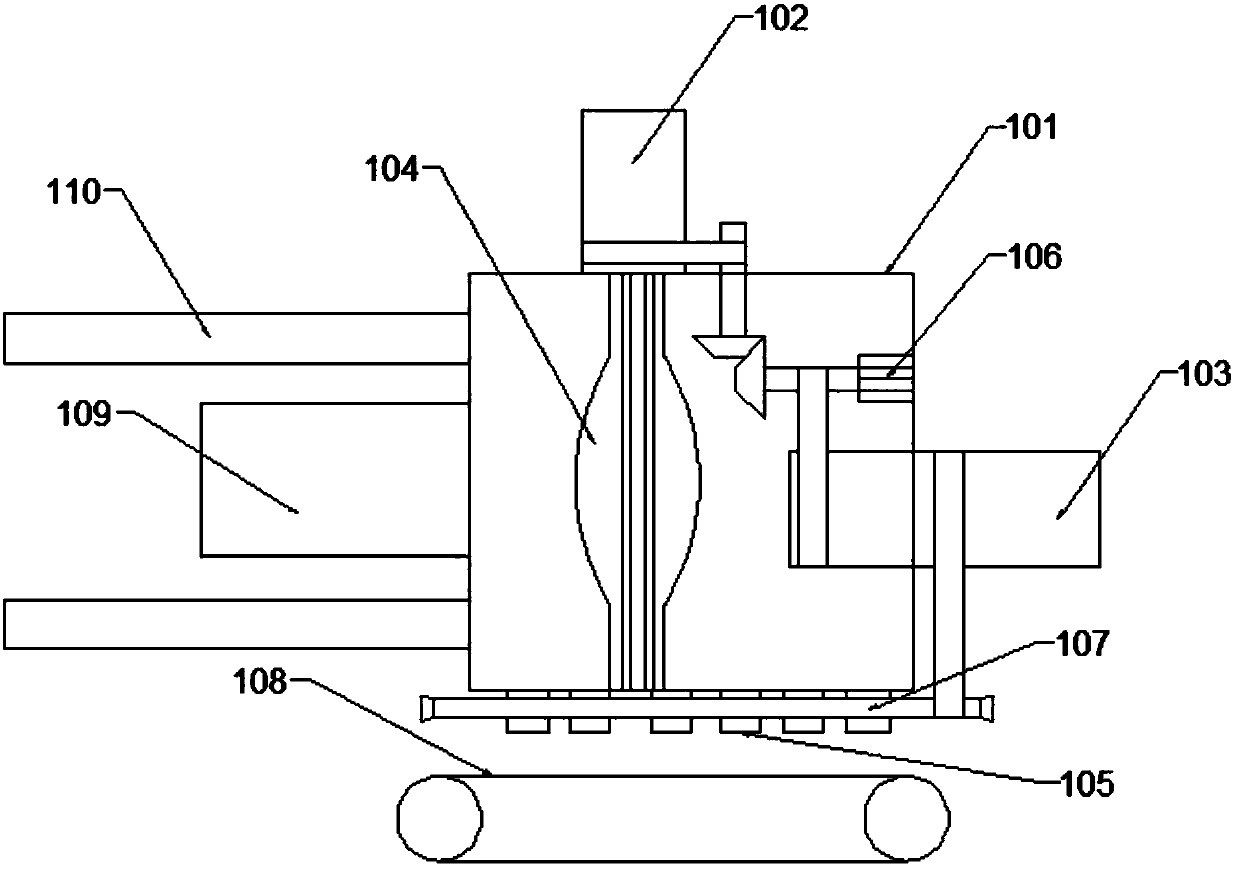

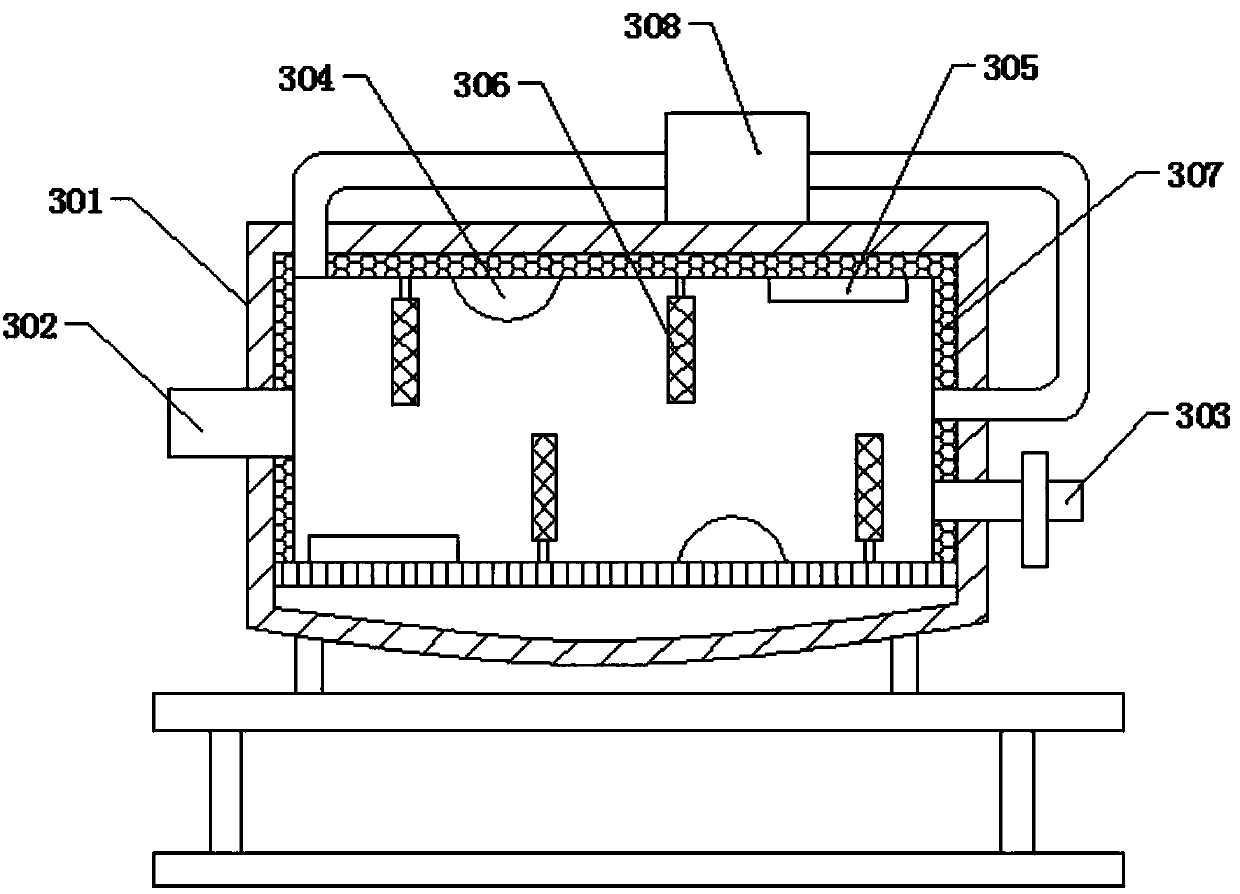

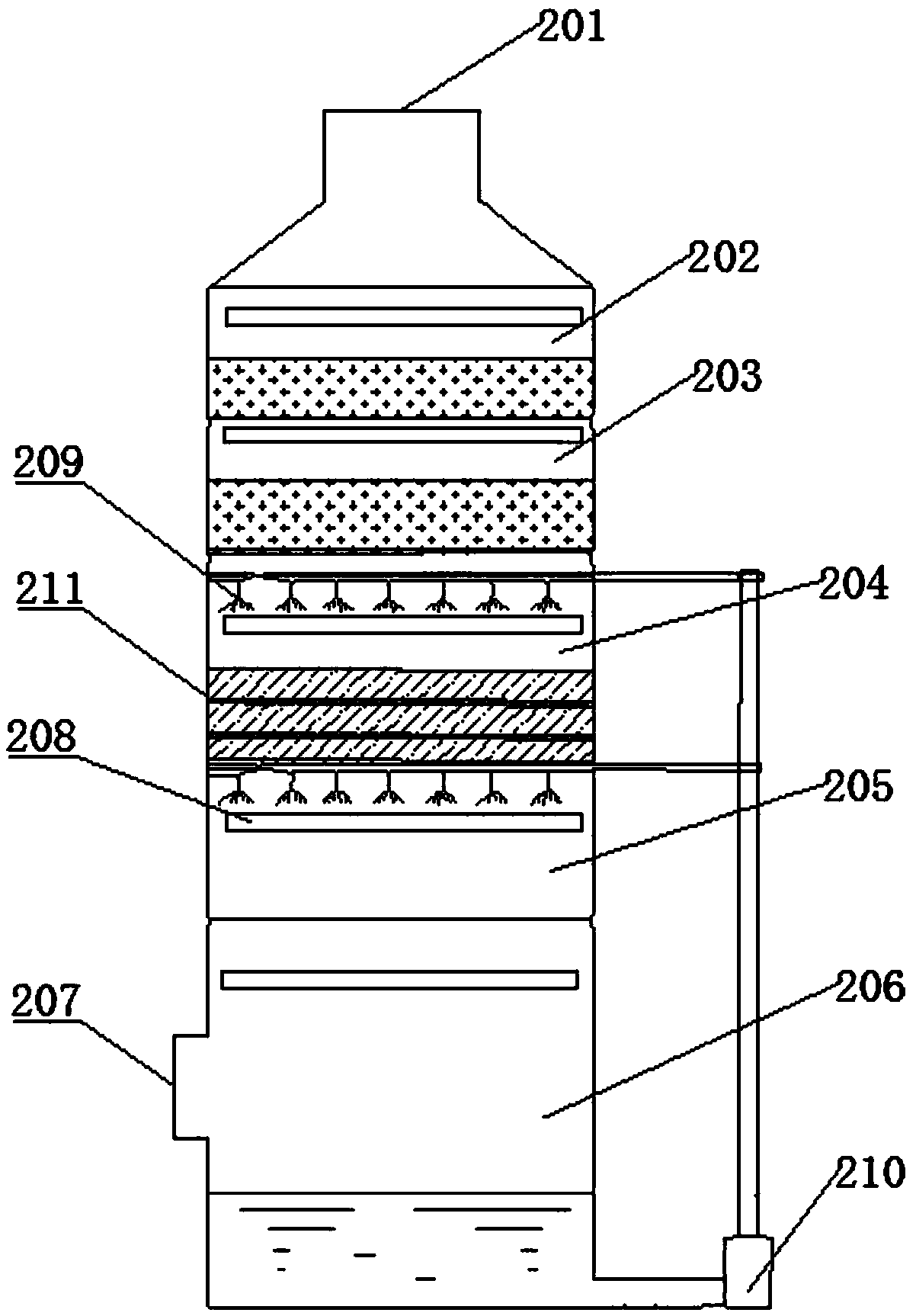

[0021] The reference signs in the accompanying drawings of the description include: frame 101, upper air inlet pipe 102, side air inlet pipe 103, filter bag 104, discharge pipe 105, motor 106, water pipe 107, conveyor belt 108, main air outlet pipe 109, outlet Air duct 110, air outlet 201, second demist chamber 202, first demist chamber 203, second spray chamber 204, first spray chamber 205, air inlet chamber 206, air inlet 207, maintenance window 208, Nozzle 209, water pump 210, horizontal plate with holes 211, reaction box 301, air inlet pipe 302, air outlet pipe 303, ultraviolet lamp 304, reflector 305, catalytic enzyme pipe 306, sodium peroxide reaction layer 307, circulation air pump 308. .

[0022] This embodiment provides a treatment method for organic waste gas, comprising the following steps:

[0023] A. Waste gas collection. The organic waste gas in the workshop is collected through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com