Method for preparing high filling polyvinyl chloride or polyolefin composite material by employing industrial solid wastes

A polyvinyl chloride and composite material technology, which is applied in the field of chemical material preparation, can solve the problems that the mechanical properties of composite materials need to be improved, the mechanical properties of composite materials are not good, and the large-scale industrial application is limited, so as to achieve high added value of products and improved processing. Performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

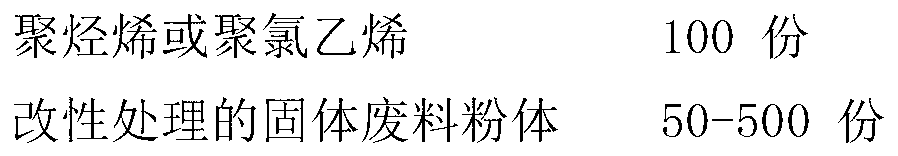

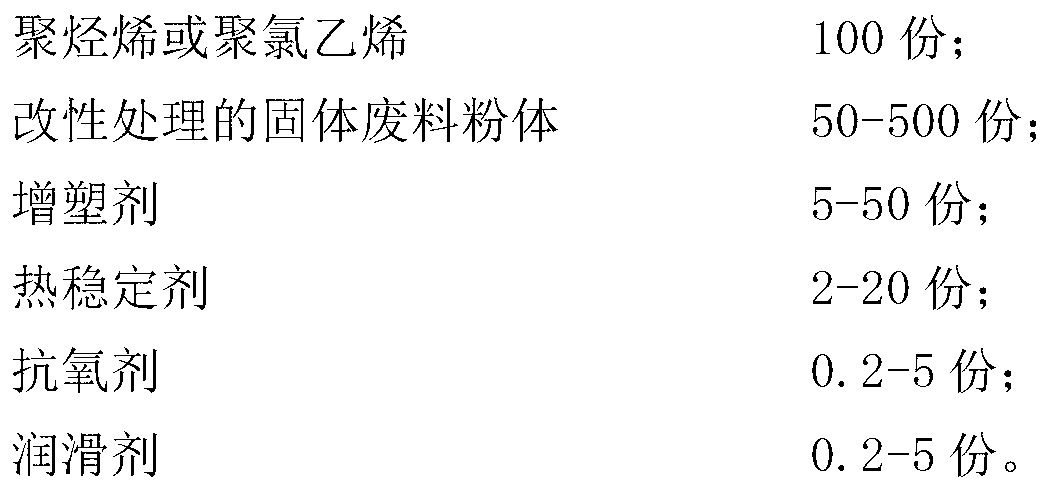

Method used

Image

Examples

Embodiment 1

[0041] The phosphogypsum was roasted at 800°C for 0.5 hours, cooled, crushed and finely ground through a 100-mesh sieve. The composite surface modifier (silane coupling agent and titanate coupling agent, the weight ratio of the two is 1:0.1) is used to modify the surface of the above phosphogypsum powder, and the mass ratio of phosphogypsum to composite modifier is 100:0.5. 100 parts of polyvinyl chloride, 500 parts of surface-modified phosphogypsum, 50 parts of plasticizer (palm oil and dioctyl phthalate, the weight ratio of the two is 1:0.1), heat stabilizer stearic acid 2 parts, 10100.2 parts of antioxidant, and 5 parts of lubricant polyethylene wax were uniformly mixed in a high-speed mixer, and then granulated by a plastic granulator at 170°C or directly injection-molded by an injection molding machine to make phosphogypsum filled with 80% PVC composite.

Embodiment 2

[0043] The desulfurized gypsum was roasted at 500°C for 5 hours, and after cooling, it was pulverized and finely ground through a 1000-mesh sieve. The surface modification treatment of the above-mentioned desulfurized gypsum powder is carried out by using a composite surface modifier (silane coupling agent and aluminate coupling agent, the weight ratio of which is 1:10). The mass ratio of desulfurized gypsum to composite modifier is 100:0.5. 100 parts of polyvinyl chloride, 500 parts of surface-modified phosphogypsum, 5 parts of plasticizer (epoxidized soybean oil and diisooctyl phthalate, the weight ratio of the two is 1:10), heat stabilizer 20 parts of lauric acid, 10765 parts of antioxidant, and 0.2 parts of lubricant paraffin are uniformly mixed in a high-speed mixer, and then granulated by a plastic granulator at 250 ° C or directly injection-molded by an injection molding machine to make high-filled polyethylene. composite material.

Embodiment 3

[0045] The fly ash was roasted at 200°C for 1 hour, and after cooling, it was pulverized and finely ground through a 300-mesh sieve. Use composite surface modifier (aluminate coupling agent and titanate coupling agent, the weight ratio of the two is 1:1) to carry out surface modification treatment on the above fly ash powder, fly ash and composite modification The dose ratio is 100:2. 100 parts of polypropylene, 100 parts of surface-modified fly ash, 25 parts of plasticizer (peanut oil and diallyl phthalate, the weight ratio of the two is 1:5), 10 parts of heat stabilizer isooctanoic acid 2 parts of antioxidant CA, 1 part of lubricant polystearic acid are evenly mixed in a high-speed mixer, granulated by a plastic granulator at 200 ℃ or directly injection molded by an injection molding machine to make a high-filling polypropylene compound Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com