Oil resistant low temperature resistant rubber composition

A technology of rubber composition and nitrile rubber, applied in the field of rubber composition, can solve problems such as poor low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

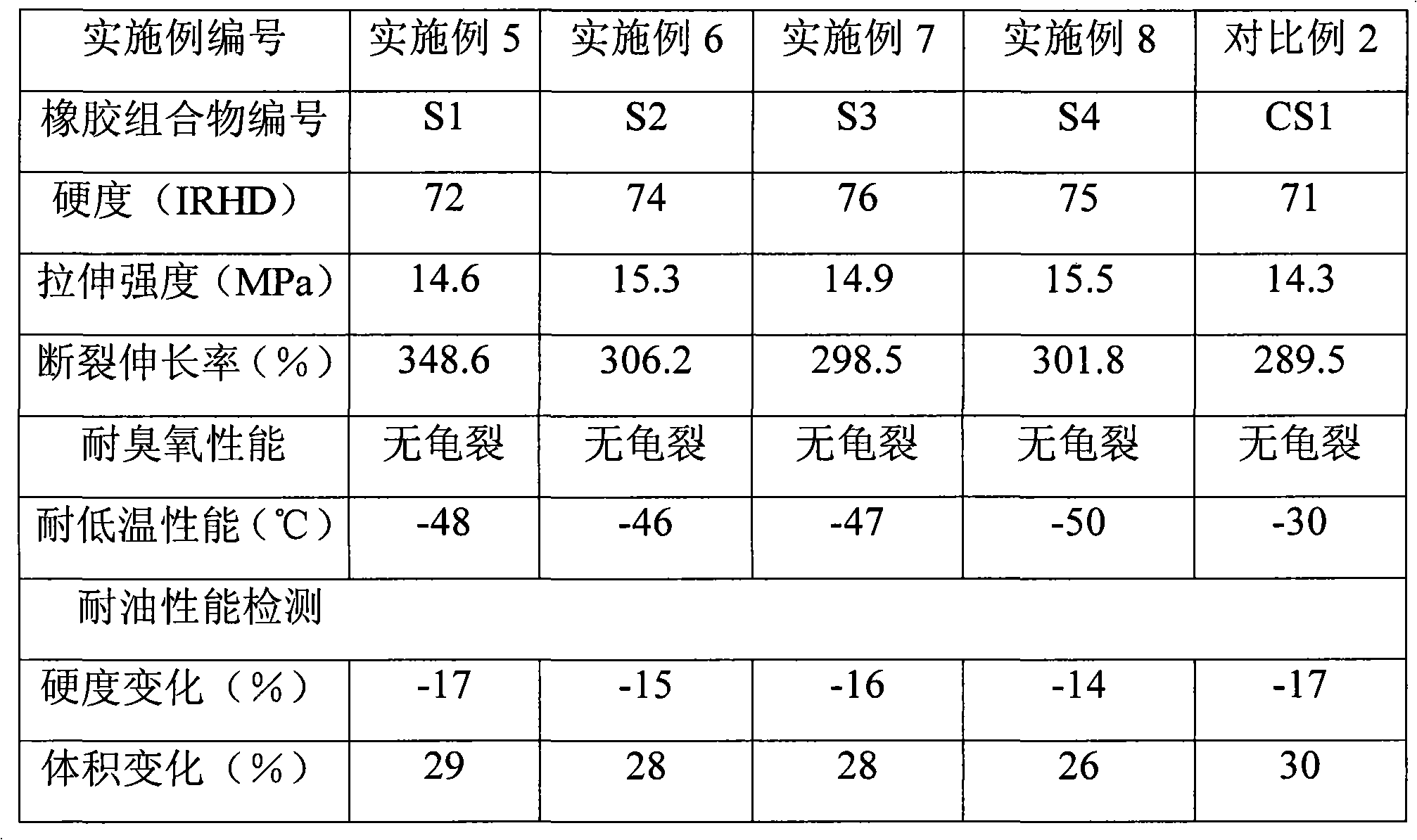

Examples

Embodiment 1

[0038] This example is used to illustrate the rubber composition provided by the present invention.

[0039]Add 60 parts by weight of nitrile rubber (Japan JSR Company, N230S) and 40 parts by weight of polyvinyl chloride (Sinopec Qilu Petrochemical Company, S-700) to a 0.5-liter internal mixer, and mix at 120 ° C for 5 Minutes, then add 1.5 parts by weight of stearic acid (Dandong Longze Chemical Co., Ltd., 200 type), 1.5 parts by weight of zinc oxide (Guangxi Liuzhou Zinc Products Co., Ltd., Bajiao brand) and 1.0 parts by weight of antioxidant MB (Zhejiang Huangyan Zhedong Rubber Chemical Co., Ltd.), 1.5 parts by weight of antioxidant 4010NA (Shandong Sunnic Chemical Co., Ltd.) and 0.1 part by weight of anti-scorch agent CTP (Shandong Yanggu Huatai Chemical Co., Ltd.), mixed at 120 ° C for 8 Minutes, then add 50 parts by weight of carbon black N550 (Shanghai Cabot), 7.0 parts by weight of dimethyl sebacate (Hangzhou Nature Organic Chemical Industry Co., Ltd., industrial grade...

Embodiment 2

[0041] This example is used to illustrate the rubber composition provided by the present invention.

[0042] Add 80 parts by weight of nitrile rubber (Japan JSR Company, N230S) and 20 parts by weight of polyvinyl chloride (Sinopec Qilu Petrochemical Company, S-700) into a 0.5-liter internal mixer, and mix at 120 ° C for 5 Minutes, then add 2.0 parts by weight stearic acid (Dandong Longze Chemical Co., Ltd., 200 type) and 1.5 parts by weight antioxidant BLE (Shanghai Rubber Auxiliaries Factory), 2.0 parts by weight antioxidant DNP (Zhejiang Huangyan Zhedong Rubber Auxiliary Chemical Co., Ltd.) and 0.1 parts by weight of anti-scorch agent MTP (Yancheng Bairuite Fine Chemical Co., Ltd.), mixed for 8 minutes at 120 ° C, then added 70 parts by weight of carbon black N550 (Shanghai Cabot), 10 parts by weight Dibutyl sebacate (Hangzhou Nature Organic Chemical Industry Co., Ltd., industrial grade) and 20 parts by weight of dibutoxyethyl adipate (Nanjing Jinshi Technology Development C...

Embodiment 3

[0044] This example is used to illustrate the rubber composition provided by the present invention.

[0045] Add 70 parts by weight of nitrile rubber (Japan JSR Company, N230S) and 30 parts by weight of polyvinyl chloride (Sinopec Qilu Petrochemical Company, S-700) to a 0.5-liter internal mixer, and mix at 120 ° C for 5 Minutes, then add 1.0 parts by weight of stearic acid (Dandong Longze Chemical Co., Ltd., 200 type), 2.0 parts by weight of zinc oxide (Guangxi Liuzhou Zinc Products Co., Ltd., Bajiao brand) and 2.0 parts by weight of antioxidant 4010NA (Shandong Sennics Chemical Co., Ltd.), 1.0 parts by weight of polyethylene wax (Guangzhou Chuangbo Chemical Co., Ltd., H110, weight average molecular weight 2000) and 0.5 parts by weight of anti-scorch agent MTP (Yancheng Bairuite Fine Chemical Co., Ltd.), Mix for 8 minutes at 120°C, then add 70 parts by weight of carbon black N550 (Shanghai Cabot), 7 parts by weight of dioctyl sebacate (Hangzhou Nature Organic Chemical Industry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com