Low temperature rubber capsule used in oil conservator for transformer and preparation process

A technology of oil conservator and transformer, which is applied in transformer/inductor cooling, textile and paper making, etc. It can solve the problem that the transformer oil conservator capsule cannot be used normally, and achieve the effect of ensuring the use and oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

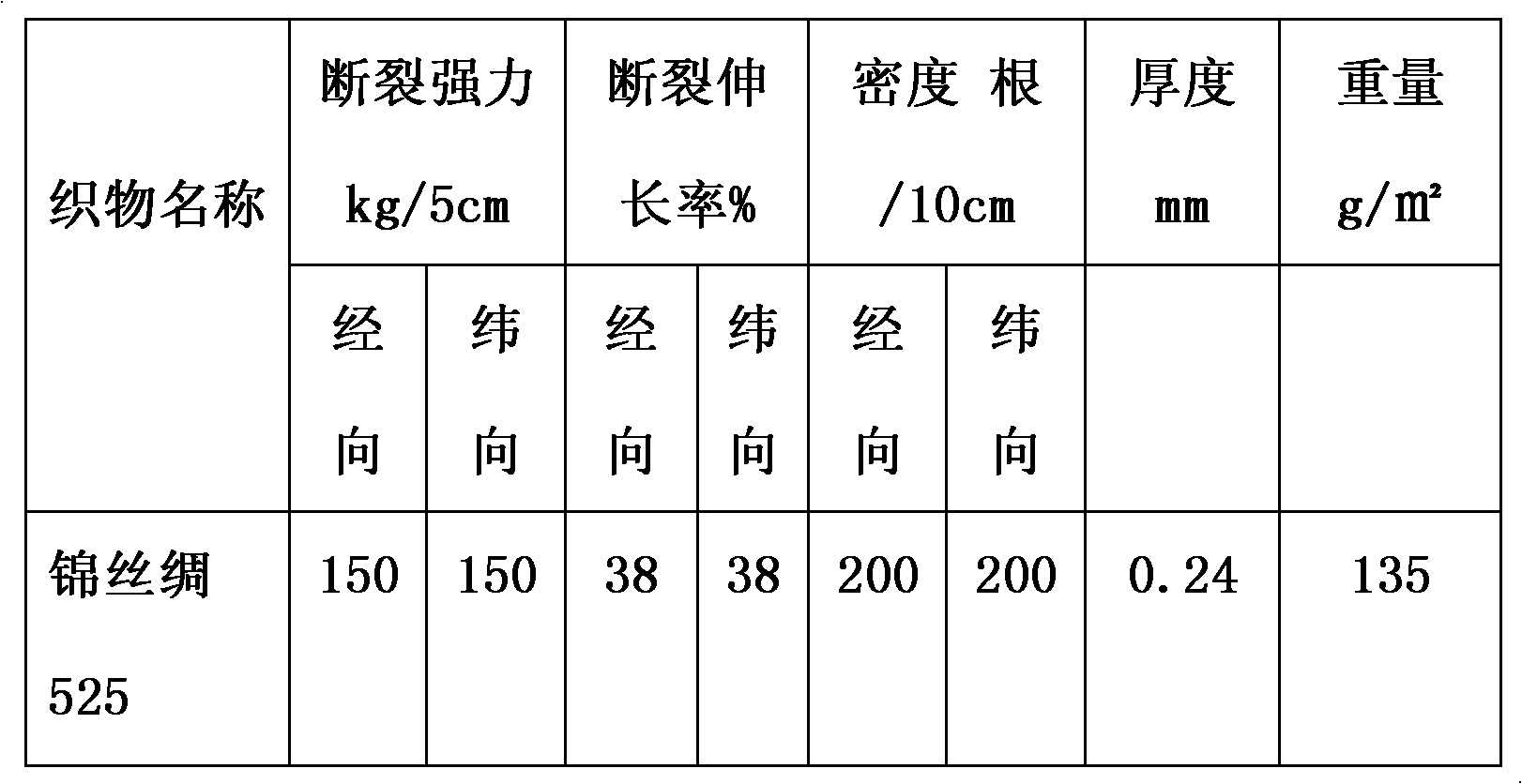

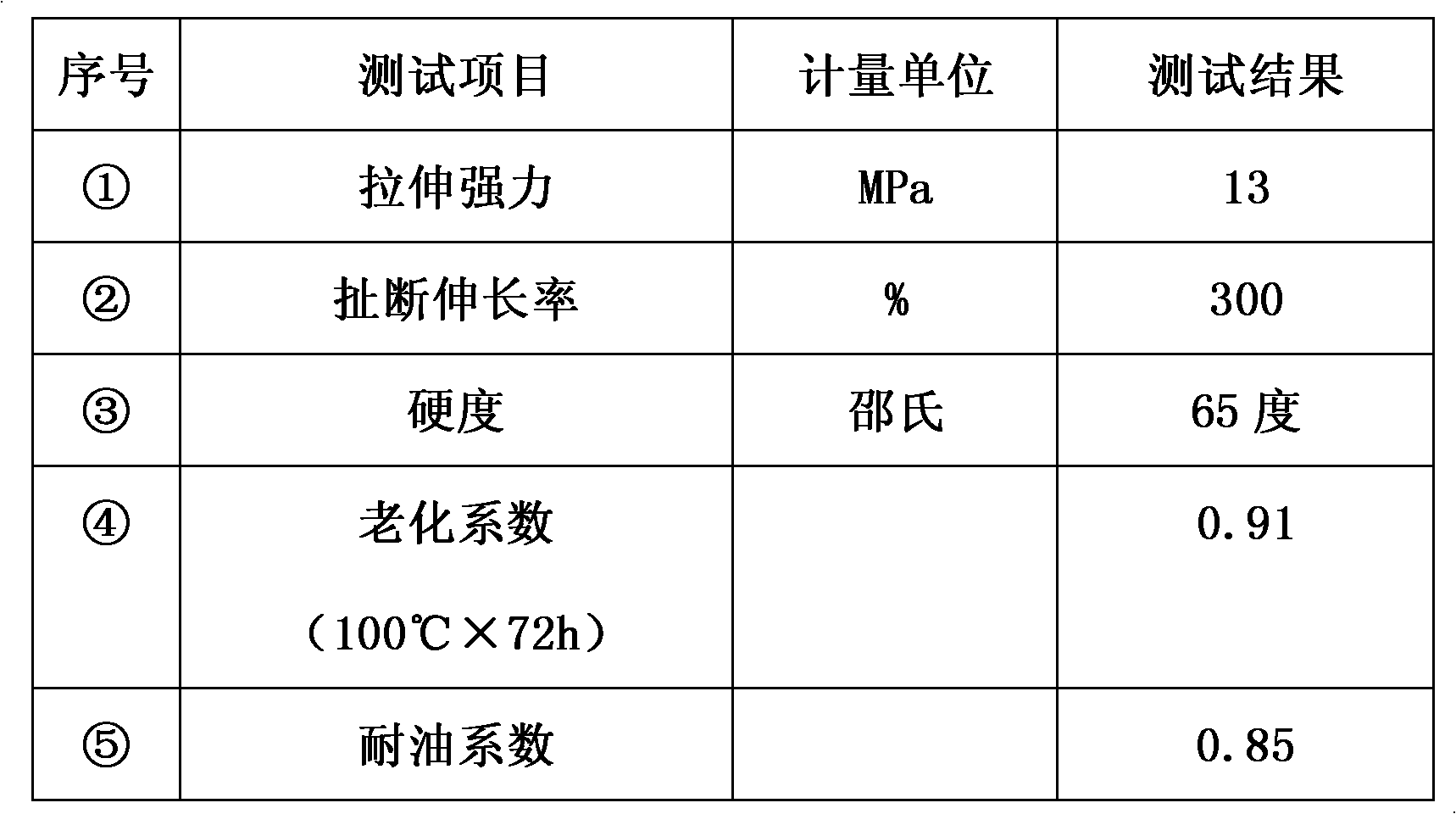

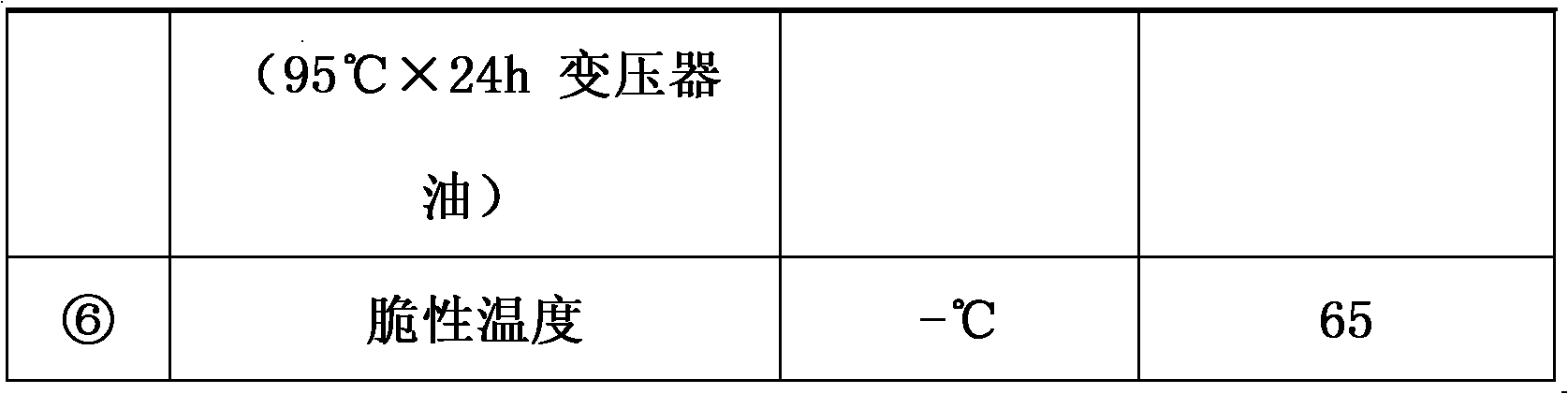

[0022] Brocade silk 525, a fiber fabric with high strength, excellent cold resistance, and softness at -60°C, is used as the capsule skeleton material. The surface of the capsule skeleton material brocade silk 525 is coated with rubber with good oil resistance, heat resistance, and cold resistance. , wherein the rubber material is composed of nitrile-26, nitrile-18, reinforcing agent high wear-resistant carbon black, spray carbon black and plasticizer dioctyl sebacate DOS, and the addition ratio is: high wear-resistant carbon black: Spray carbon black = 1.8:1; the addition amount of each component of the rubber material is calculated by weight percentage: 35% of nitrile-26, 20% of nitrile-18, 35% of reinforcing agent, and 10% of plasticizer.

[0023] The preparation process of the low-temperature capsule of the transformer oil conservator provided by the present invention includes processes such as gluing, calendering, molding and vulcanization, among which

[0024] (1) Gluing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com