Salt-free, pickling-free, short-process and little-chromium tanning method

An acid-free, short-process technology, applied in chemical treatment before tanning, small raw hide/large hide/leather/fur treatment, tanning treatment, etc., to reduce pollution, easy to store, and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

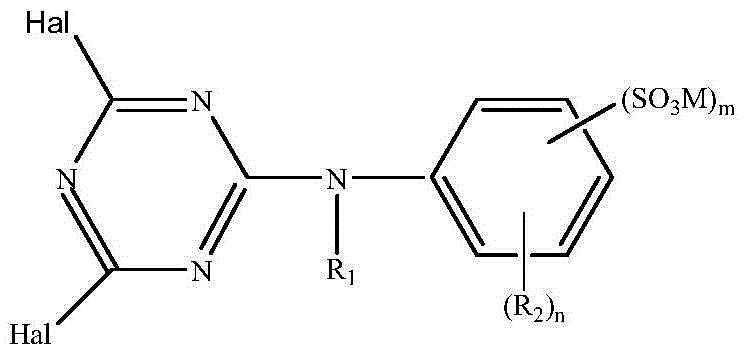

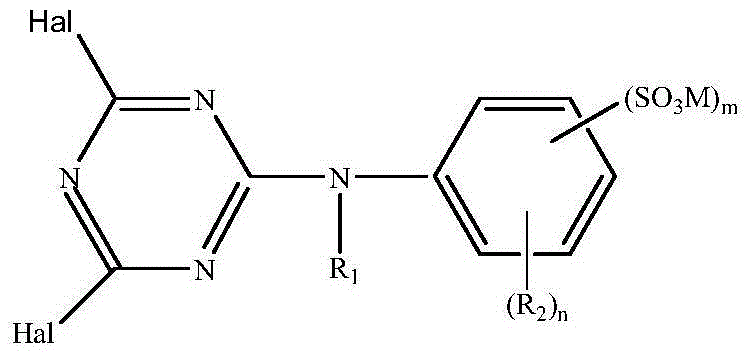

Method used

Image

Examples

Embodiment 1

[0044] (1) Immersion, depilation, and liming are the same as traditional techniques.

[0045] (2) Ammonia-free deashing and softening

[0046] Take 100 kg of cauliflower skin, use 50 kg of water at 30°C, 0.2 kg of formic acid, 1.5 kg of lactic acid, 1 kg of propionic acid, rotate for 120 minutes, pH is 8, use 1 kg of neutral protease, rotate for 120 minutes, wash with water .

[0047] (3) Non-chrome tanning agent tanning

[0048] Method 1: Use 50 kg of water with a temperature of 18°C, add 4 kg of non-chrome tanning agent I in the drum, rotate for 2 hours, then add 1.0 to 1.6 parts of baking soda (dilute with 10 times of water, add to the drum in 4 times) 60 minutes in total), adjust the pH value of the acid solution to 7.0, then add 50°C hot water to make the temperature inside the drum 35°C, and rotate for 220 minutes.

[0049] Method 2: Use 30 kg of water at a temperature of 32°C, add 8 kg of non-chrome tanning agent II to the drum, rotate for 2 hours, then add 60 kg of ...

Embodiment 2

[0059] (1) Immersion, depilation, and liming are the same as traditional techniques.

[0060] (2) Ammonia-free deashing and softening

[0061] Take 100 kg of cauliflower skin, use 100 kg of water at 33°C, 0.5 kg of formic acid, 3.5 kg of deliming aid, rotate for 150 minutes, adjust the pH to 8.5, use 1.5 kg of neutral protease, rotate for 150 minutes, and wash with water.

[0062] (3) Non-chrome tanning agent tanning

[0063] Method 1: Use 100 kg of water with a temperature of 22°C, add 6 kg of non-chrome tanning agent I in the drum, rotate for 3 hours, then add 1.0 to 1.6 parts of baking soda (dilute with 10 times of water, add to the drum in 4 times) 60 minutes in total), adjust the pH value of the acid solution to 7.5, then add hot water at 60°C to make the temperature inside the drum 45°C, and rotate for 280 minutes.

[0064] Method 2: Use 50kg of water at a temperature of 35°C, add 10kg of non-chrome tanning agent II to the drum, rotate for 2 hours, then add 80 parts of...

Embodiment 3

[0074] (1) Immersion, depilation, and liming are the same as traditional techniques.

[0075] (2) Ammonia-free deashing and softening

[0076] Take 100 kg of cauliflower skin, use 75 kg of water with a temperature of 31.5°C, 0.35 kg of formic acid, and 3 kg of deliming aid, rotate for 135 minutes, adjust the pH to 8.2, use 1.25 kg of neutral protease, rotate for 135 minutes, and wash with water.

[0077] (3) Non-chrome tanning agent tanning

[0078] Method one: use 75 kilograms of water with a temperature of 20 ° C, add 5 kilograms of non-chrome tanning agent I in the drum, rotate for 2.5 hours, then add 1.0 to 1.6 parts of baking soda (dilute with 10 times of water, add to the drum in 4 times) 60 minutes in total), adjust the pH value of the acid solution to 7.2, then add hot water at 55°C to make the temperature inside the drum 40°C, and rotate for 250 minutes.

[0079] Method 2: Use 40kg of water at a temperature of 33.5°C, add 9kg of non-chrome tanning agent II to the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com