Preparation method of flexible high-strength textile-based conductive composite material

A conductive composite material and textile technology, which is applied in the preparation of conductive composite materials and the preparation of flexible high-strength textile-based conductive composite materials, can solve the problems of poor mechanical properties, no self-healing performance, poor sensing performance, etc., and achieve self- High viscous strength, considerable social and economic benefits, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

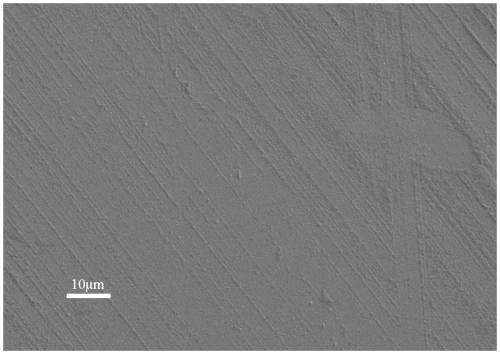

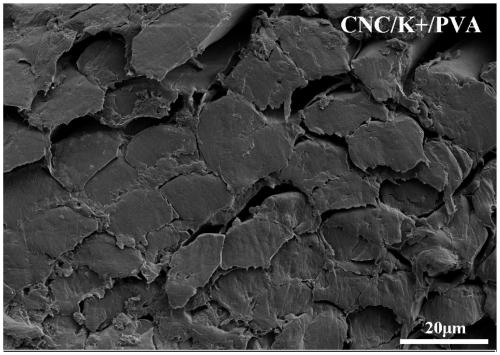

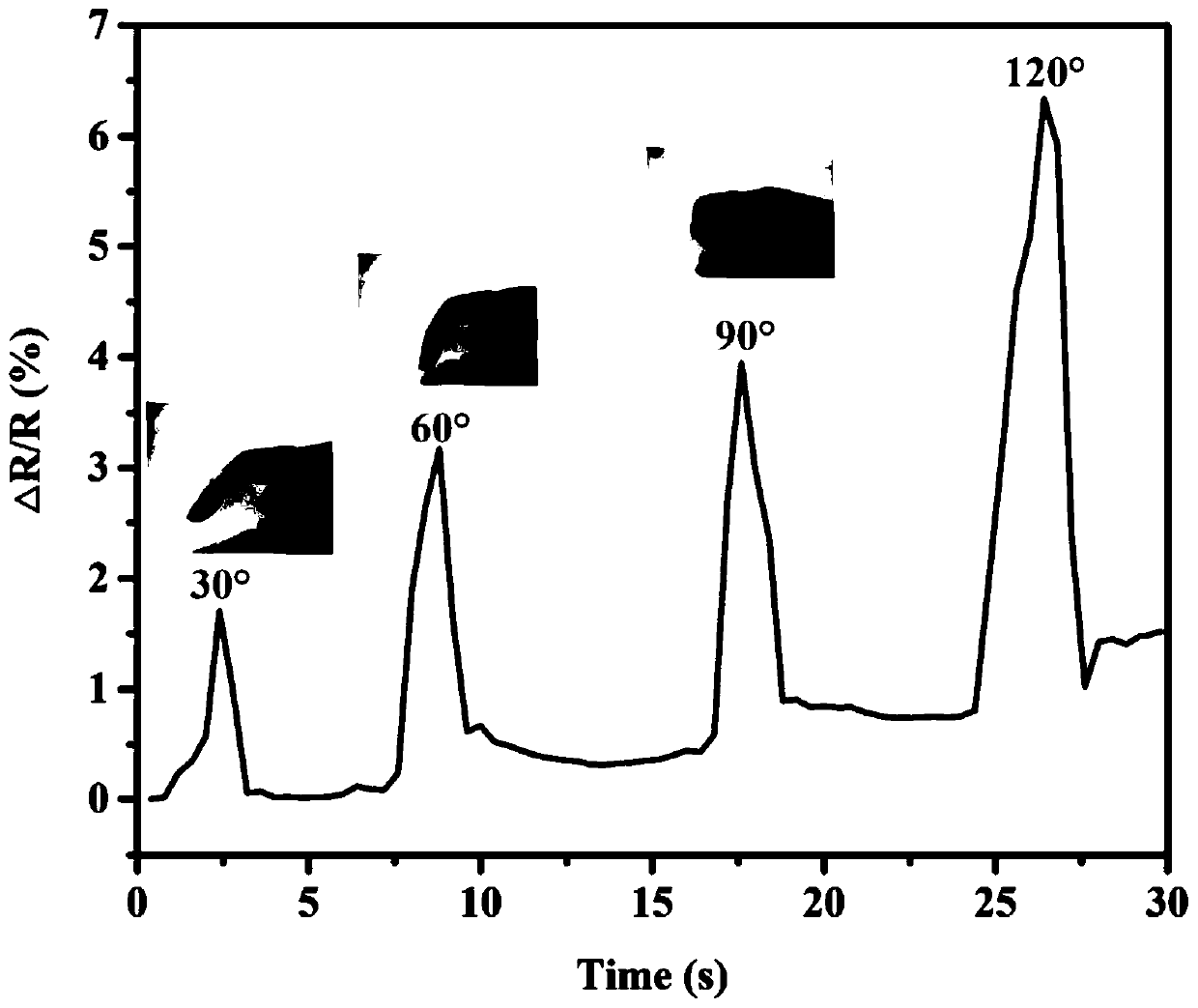

Embodiment 1

[0037]Prepare CNC, and prepare a CNC dispersion with a solid-to-liquid ratio of 1g: 50mL, and ultrasonicate for 30 minutes; prepare a PVA solution with a solid-to-liquid ratio of 1g: 8mL. PVA is purchased from Aladdin Company, with a molecular weight of 145,000, and heated in a water bath at 85°C. And stir (rotating speed is 35r / min) 120min; Preparation ratio is 1g: 100mL conductive aniline acidic solution, wherein aniline is purchased from Aladdin Company, AR, purity ≥ 99.5%, ultrasonic 30min; Preparation solid-liquid ratio is 1g: 6mL Initiator ammonium persulfate solution, wherein ammonium persulfate is purchased from Aladdin Company, AR, purity ≥ 98%, ultrasonic 30min; KCl solution with a solid-liquid ratio of 1g: 15mL is prepared, and potassium chloride is purchased from MACKLIN Company, AR , purity ≥ 99.5%, ultrasonication for 30min; under low temperature (0°C ice bath) stirring (speed: 25r / min), the above-mentioned conductive aniline acidic solution was added to the CNC d...

Embodiment 2

[0039] Prepare CNC and prepare a CNC dispersion with a solid-to-liquid ratio of 1g: 50mL, and ultrasonicate for 25min; prepare a PVA solution with a solid-to-liquid ratio of 1g: 7.5mL. PVA is purchased from Aladdin, with a molecular weight of 145,000, and heated in a water bath at 90°C , and stirred (rotating speed is 30r / min) 100min; preparation ratio is 1g: 100mL conductive aniline acidic solution, wherein aniline is purchased from Aladdin Company, AR, purity ≥ 99.5%, ultrasonic 30min; preparation solid-liquid ratio is 1g: 6mL initiator ammonium persulfate solution, wherein ammonium persulfate is purchased from Aladdin Company, AR, purity ≥ 98%, ultrasonication for 30min; prepare ZnCl with a solid-liquid ratio of 1g: 8mL 2 Solution, in which zinc chloride is purchased from MACKLIN company, AR, purity ≥ 98%, ultrasonic 30min; under low temperature (0 ℃ ice bath) stirring (15r / min) state, the above-mentioned conductive aniline acidic solution is added to CNC to disperse soluti...

Embodiment 3

[0041] Prepare CNC, prepare a CNC dispersion with a solid-to-liquid ratio of 1g:60mL, and sonicate for 20 minutes; prepare a PVA solution with a solid-to-liquid ratio of 1g:5mL. PVA is purchased from Aladdin, with a molecular weight of 145,000, and heated in a water bath at 90°C. And stir (rotating speed is 30r / min) 140min; Preparation ratio is 1g: 80mL conductive pyrrole acidic solution, wherein pyrrole is purchased from Aladdin Company, monomer molecular weight is 67.09, AR, purity ≥ 99%, ultrasonic 40min; Preparation solid The liquid ratio is 1g: 8mL initiator potassium persulfate solution, wherein potassium persulfate is purchased from Aladdin Company, and the molecular formula is K 2 S 2 o 8 , with a molecular weight of 270.32, sonicated for 10 minutes; prepared FeCl with a solid-liquid ratio of 1g: 20mL 3 Solution, in which ferric chloride is purchased from MACKLIN company, CP, molecular weight is 162.2, ultrasonic 10min; under low temperature (0 ℃ ice bath) stirring (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com