Method for softening and dyeing soybean straw

A technology of soybean straw and dyeing method, applied in the field of straw dyeing treatment, can solve the problems of low service life, unsightly color, dull color, etc., and achieve the effects of enhanced breaking strength, improved resource utilization efficiency, bright, bright, uniform and lustrous color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

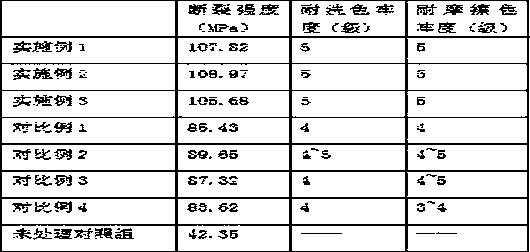

Examples

Embodiment 1

[0018] In the embodiment of the present invention, a softening and dyeing method of soybean stalks, the specific method is as follows:

[0019] (1) Trim the harvested soybean stalks and keep the middle stalks, immerse them in a magnesium sulfate solution with a mass fraction of 4.2% and a temperature of 43°C for 23 minutes, drain the liquid until there is no water dripping, and put it in the freezer Freeze for 33 minutes, take it out, place it in a constant temperature steam at 86°C for 38 minutes, take it out, and dry it at 40°C until the moisture content is 7%~9%;

[0020] (2) Submerge the soybean stalks treated in step (1) in the dyeing agent for 110 minutes, remove the leaching agent until there is no water dripping, and place it in the electric field for 43 minutes;

[0021] The dyeing agent is made of the following raw materials in parts by weight: 11 parts of fresh cockscomb petals, 15 parts of carrots, 26 parts of fresh celery leaves, 82 parts of fresh ryegrass, 2.2 pa...

Embodiment 2

[0029] In the embodiment of the present invention, a softening and dyeing method of soybean stalks, the specific method is as follows:

[0030] (1) Trim the harvested soybean stalks and keep the middle stalks, immerse them in a magnesium sulfate solution with a mass fraction of 4.3% and a temperature of 44°C for 24 minutes, drain the liquid until there is no water dripping, and put it in the freezer Freeze for 36 minutes, take it out, place it in constant temperature steam at 88°C for 40 minutes, take it out, and dry it at 41°C until the moisture content is 7%~9%;

[0031] (2) Submerge the soybean stalks treated in step (1) in the dyeing agent for 115 minutes, remove the leaching agent until there is no water dripping, and place it in the electric field for 45.5 minutes;

[0032] The dyeing agent is made of the following raw materials in parts by weight: 11.5 parts of fresh cockscomb petals, 15.5 parts of carrots, 27 parts of fresh celery leaves, 85 parts of fresh ryegrass, 2....

Embodiment 3

[0040] In the embodiment of the present invention, a softening and dyeing method of soybean stalks, the specific method is as follows:

[0041](1) Trim the harvested soybean stalks to keep the middle stalks, immerse them in a magnesium sulfate solution with a mass fraction of 4.4% and a temperature of 45°C for 25 minutes, drain the liquid until there is no water dripping, and put it in the freezer Freeze for 39 minutes, take it out, place it in a constant temperature steam at 90°C for 42 minutes, take it out, and dry it at 42°C until the moisture content is 7%~9%;

[0042] (2) Soak the soybean stalks treated in step (1) in the dyeing agent for 120 minutes, remove the leaching agent until there is no water dripping, and place it in the electric field for 48 minutes;

[0043] The dyeing agent is made of the following raw materials in parts by weight: 12 parts of fresh cockscomb petals, 16 parts of carrots, 28 parts of fresh celery leaves, 88 parts of fresh ryegrass, 2.4 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com