Patents

Literature

31results about How to "Does not produce toxic substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

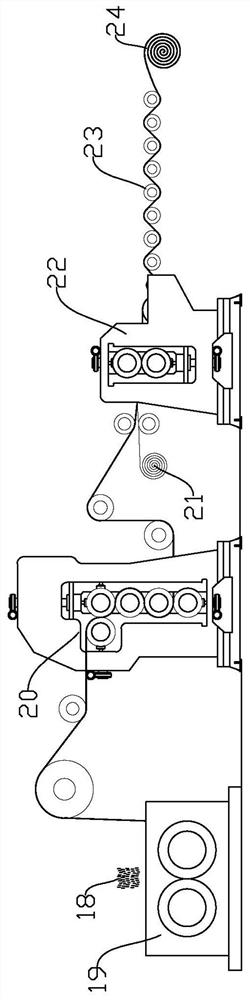

Bronzing pulp and preparation method thereof

ActiveCN103255646ARich styleRich wash fastnessTransfer printing processDyeing processWater basedSolvent

The invention discloses bronzing pulp. The bronzing pulp is prepared from the following raw materials in parts by weight: 60-80 parts of acrylic ester emulsion, 2-6 parts of deionized water, 3-10 parts of a solvent, 1-5 parts of a stabilizer, 10-20 parts of EVA (Ethylene-Vinyl Acetate) hot melt adhesive powder, 0.5-3 parts of silica, 0.2-0.5 part of a polyurethane defoaming agent, 0.1-0.5 part of a pH regulator, 0.1-0.2 part of a preservative, 0.3-1 part of an emulsion wetting agent and 0.4-2 parts of a thickener. The bronzing pulp has the beneficial effects that the bronzing pulp is water-based pulp, the raw materials are easy to obtain and environment-friendly, the production is convenient, the technology is mature, and substances harmful to the environment can not be produced; and the bronzing pulp is soft in handfeel, firm in fastness, outstanding in resistance to tension fracture and diversified in application mode, enriches the styles of textiles, and endows the textiles with the noble quality.

Owner:GUANGZHOU SHENGQIN IND

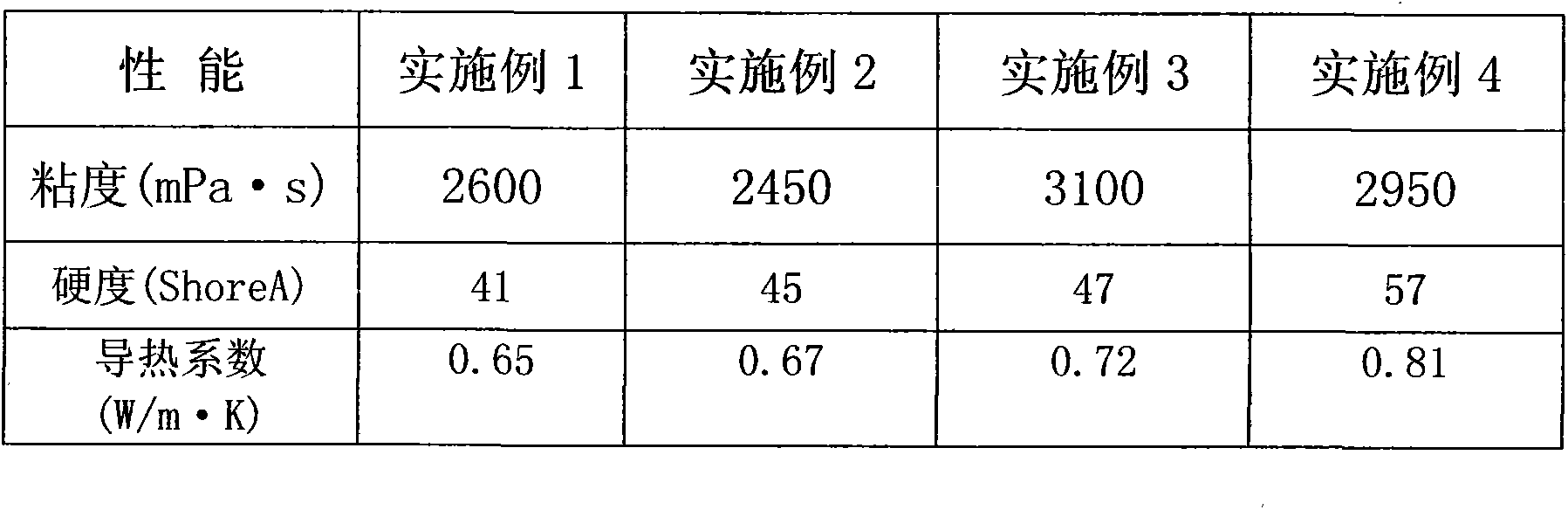

Nano hybrid material modified organosilicone heat-conductive electronic pouring sealant and preparation method of sealant

The invention relates to a nano hybrid material modified organosilicone heat-conductive electronic pouring sealant for an electronic product and a preparation method of the sealant. The preparation method comprises the following steps: adding vinyl polydimethylsiloxane, an organosilicone nano hybrid material and surface modified heat-conductive filler into a vacuum kneading machine, and dehydrating and blending for 50-100 minutes to obtain a base material at the temperature of 100-145 DEG C and the vacuum degree of (-0.07)-(-0.09)MPa; adding a hydrogen containing silicone oil crosslinking agent and a crosslinking inhibitor into the base material at the normal temperature, and fully stirring for 20-40 minutes to prepare a component A; adding a platinum catalyst into the base material, and fully stirring for 20-40 minutes to prepare a component B; and then uniformly blending the components A and B in equal weight, and defoaming for 6-12 minutes at the vacuum degree of 0.05-0.07MPa to obtain the nano modified organosilicone heat-conductive electronic pouring sealant. The pouring sealant has relatively low viscosity and good mobility. The heat conductivity coefficient is 0.6-0.85w / m.k. The cured product has good mechanical performance and electrical performance and can be cured at the normal temperature or the high temperature. The pouring sealant can be widely applied to packaging electronic elements, integrated circuit boards, circuit modules, LED (Light Emitting Diode) chips and the like.

Owner:BEIJING UNIV OF CHEM TECH

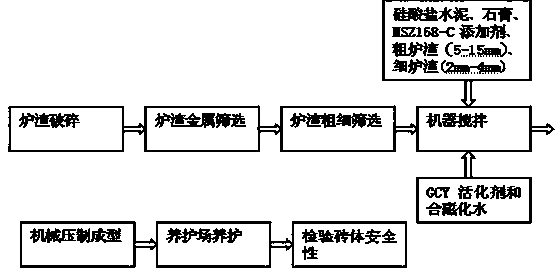

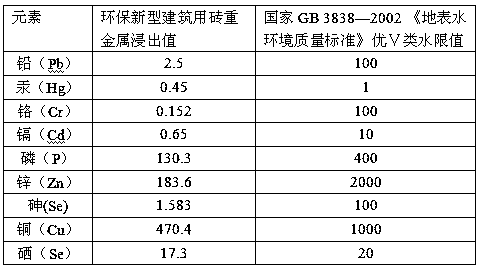

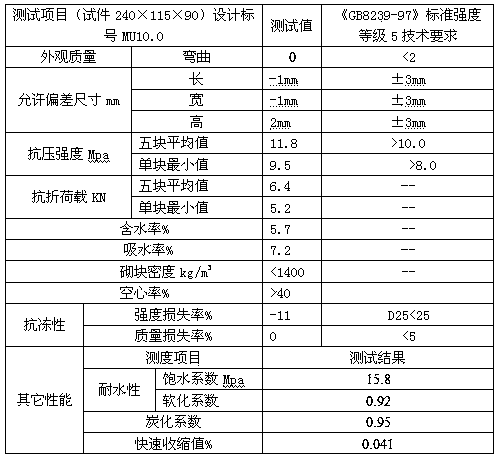

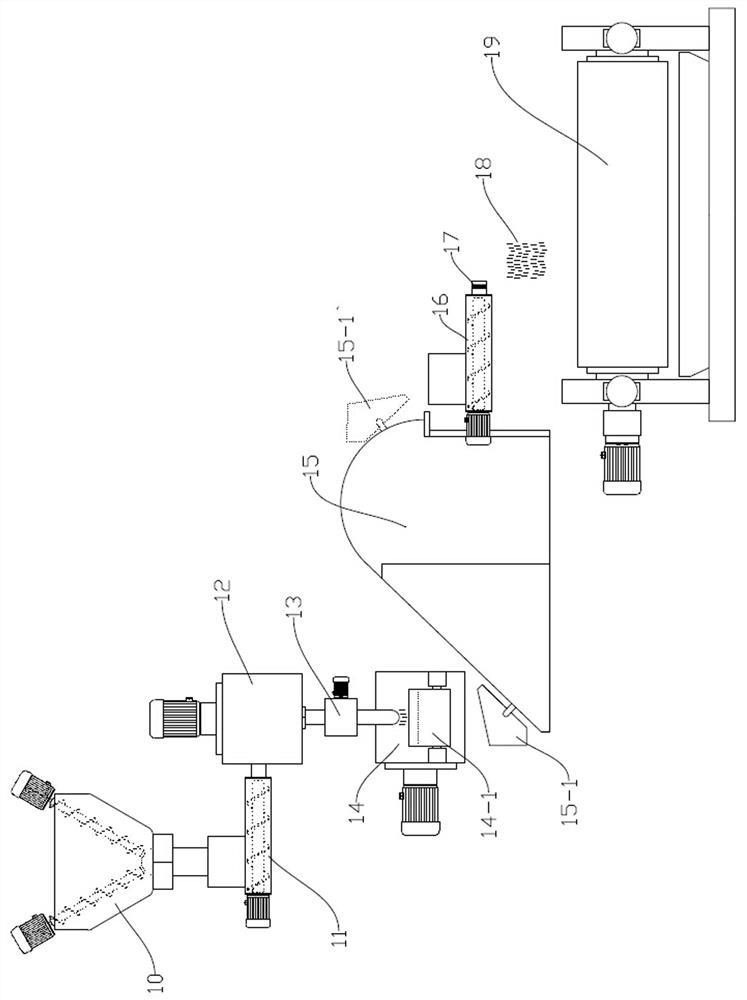

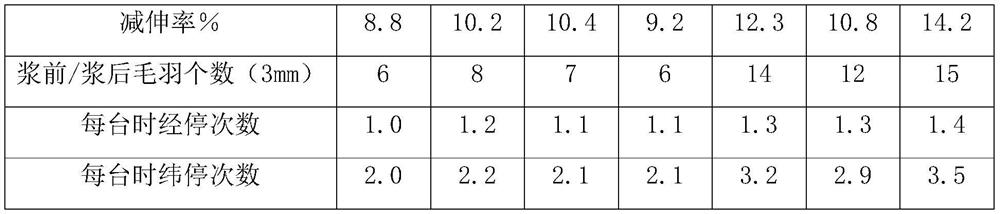

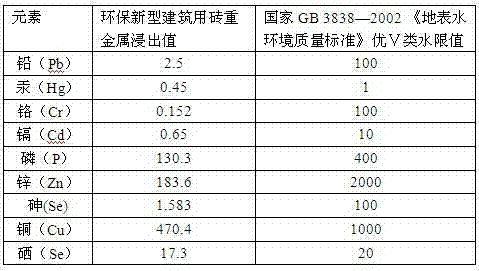

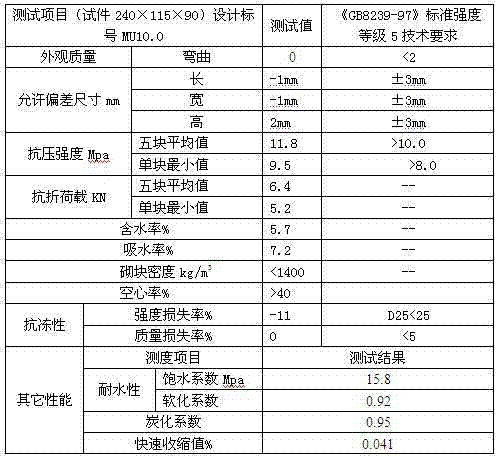

Novel environment-friendly building brick and preparation method

ActiveCN103664108ADoes not produce toxic substancesIncrease morning intensitySolid waste managementBrickThermal insulation

The invention relates to a novel environment-friendly building brick and a preparation method, and belongs to the technical field of waste disposal. The building brick comprises silicate cement, gypsum, a GCY activating agent, an MSZ168-C additive, coarse slag, fine slag and magnetized water. The preparation method comprises steps as follows: firstly, slag discharged by a slag waste incineration power plant is subjected to a series of pretreatment of hydrolytic tank washing, crushing screening, magnetic separation, flotation separation and screening of 3-15 cm particles, the slag and the MSZ168-C additive are added into an agitation tank by using a forced mixer according to a set proportion, the GCY activating agent is diluted in the magnetized water magnetized by a magnetizer, the mixture and cement are jointly added for agitation, and maintenance is performed after compression molding, so that a finished product is obtained. According to the novel environment-friendly building brick and the preparation method, the slag is prepared into a mold brick without firing, the preparation time is shortened, the burning energy consumption is reduced, emission of harmful gas in a burning process is avoided, and the environment protection effect is remarkable; and the manufactured brick is high in strength, light in weight and good in thermal insulation property, and the requirement for light mass, energy conservation and thermal insulation of wall materials of a modern building can be met.

Owner:山东环兴再生资源科技有限公司

Methods for preparing modified vinyl silicone resin and organosilicone sealing compound containing modified vinyl silicone resin

ActiveCN105860083AHigh refractive indexLow viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesUltravioletSilicone oil

The invention relates to methods for preparing modified vinyl silicone resin and an organosilicone sealing compound containing the modified vinyl silicone resin. The modified vinyl silicone resin is generated through synthesis of low-viscosity vinyl silicone resin and sulfydryl oligosiloxane containing phenyl. Specifically, the modified vinyl silicone resin is synthesized in the way of slowly adding sulfydryl oligosiloxane containing phenyl to a low-viscosity vinyl silicone resin and initiator mixing system dropwise slowly under the irradiation of a 100-500 W ultraviolet lamp at 20-35 DEG C, wherein the content of vinyl in the low-viscosity vinyl silicone resin is 0.2-2 mol%, viscosity of the low-viscosity vinyl silicone resin is 200-10000 mPa.S, and the low-viscosity vinyl silicone resin contains a linear chain, branched chains and silicone oil; the initiator is composed of a photoinitiator and a thermal initiator.

Owner:深圳市勇泰运科技有限公司

Deep drying and dewatering method

ActiveCN103868330AEasy to vaporizeKeep dryDrying solid materials without heatToxic materialPollution

The invention provides a deep drying and dewatering method of solid materials. The method includes the following steps that firstly, drying reagents which are lower than water in polarity, surface tension and boiling point are fed into a container where dried objects are placed; secondly, after the drying reagents are fed in, the container is vacuumized; thirdly, inert gas with high purity and for drying is fed into the container to remove residual drying reagents. By means of competitive adsorption of the drying reagents and water on surfaces of dried materials, hydrone on the surfaces of the dried materials is displaced, accordingly, the drying effect on the solid materials is greatly improve, a better dewatering effect is realized, drying can be carried out more thoroughly, higher requirements for the drying effect of certain industries can be met, and especially production bottlenecks caused by the fact the requirement for water is very high in industries such as lithium electricity industry can be broken; according to the method, energy is saved, the environment is protected, toxic substances cannot be produced, and the method is free from pollution, environmentally friendly and efficient.

Owner:VIGOR GAS PURIFICATION TECHNOLOGIES (SUZHOU) CO LTD

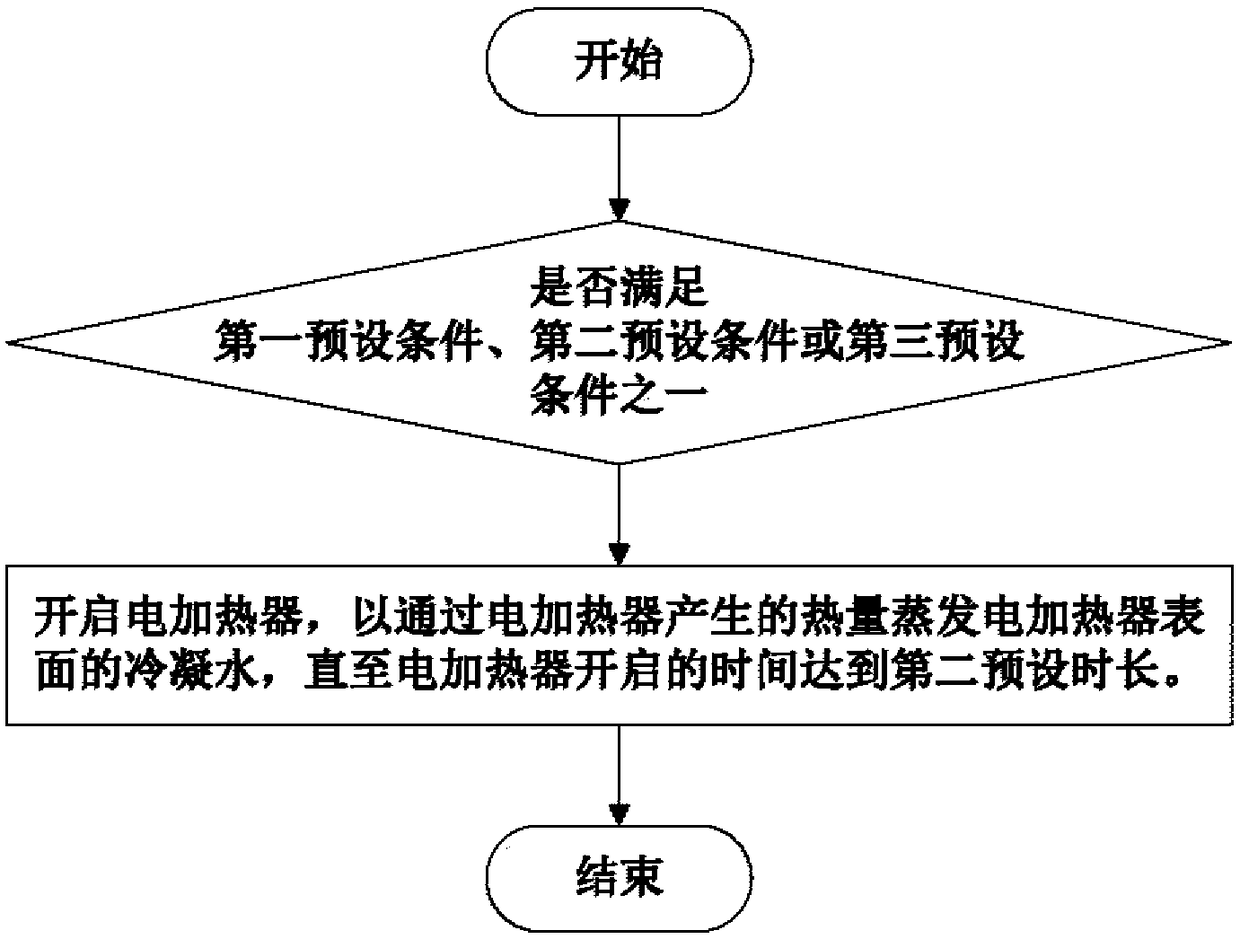

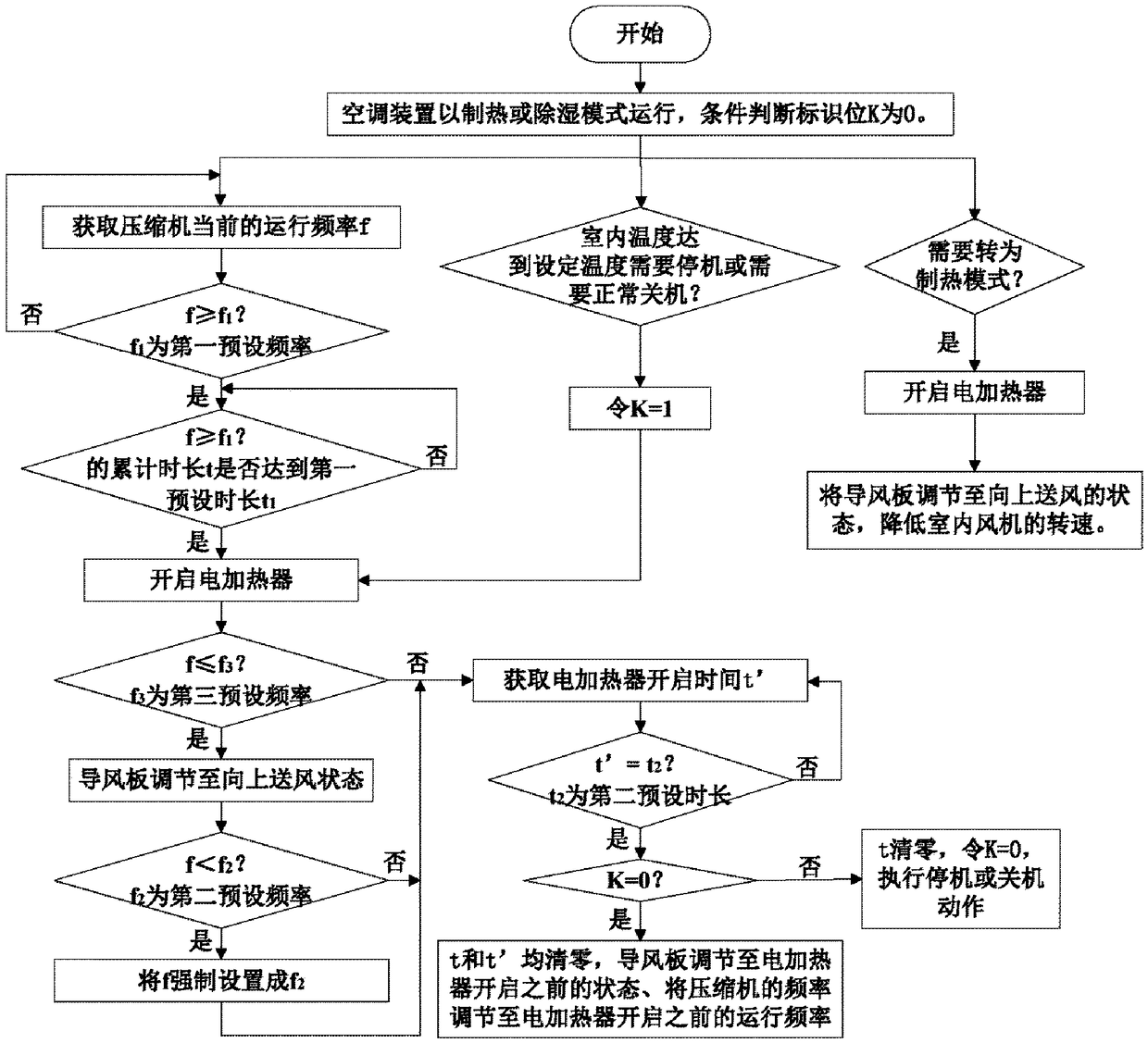

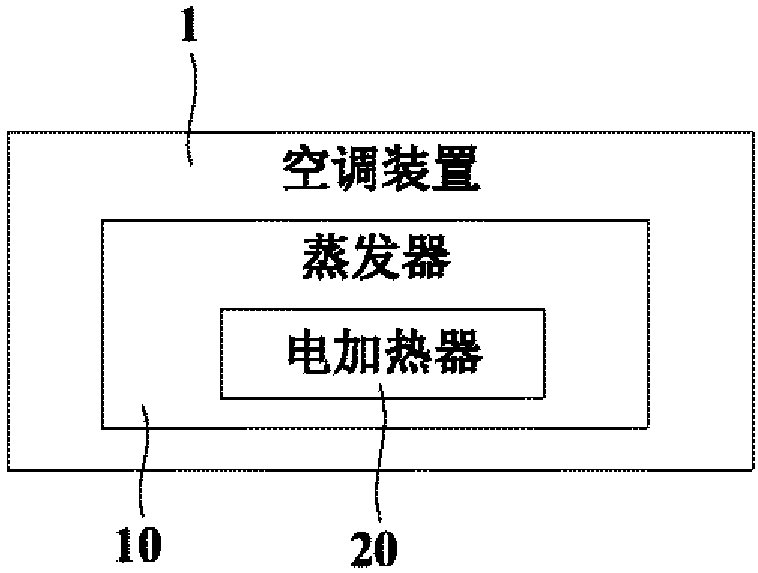

Air conditioning device and control method thereof

ActiveCN108151245APurge airQuick and effective removalMechanical apparatusCondensate preventionStart timeEngineering

The invention relates to an air conditioning device and a control method thereof. The control method is used for preventing the surface of an electric heater of the air conditioning device from beingcorroded and comprises steps as follows: when a first preset condition, a second preset condition or a third preset condition is met, the electric heater is started, condensate water on the surface ofthe electric heater is evaporated through heat produced by the electric heater until the starting time of the electric heater reaches second preset duration. The first preset condition is that cumulative duration of operation of a compressor of the air conditioning device at frequency higher than or equal to first preset frequency in a refrigeration or dehumidification mode reaches first preset duration; the second preset condition is that when temperature of the indoor environment reaches the preset temperature in the refrigeration or dehumidification mode, breaking halt is required, or whena shutdown signal for indicating the air conditioning device to stop operating is received, normal shutdown is required; the third preset condition is that the air conditioning device is required tobe switched in a heating mode and the compressor stops running. Therefore, the surface of the electric heater of the air conditioning device can be prevented from being corroded, and the air conditioning device is safe, healthy, environmentally friendly and low in cost.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Environment-friendly organic-inorganic composite coating and preparation method thereof

InactiveCN104789054ALow costImprove performanceAnti-corrosive paintsSolid contentCorrosion resistant

The invention discloses an environment-friendly organic-inorganic composite coating. The environment-friendly organic-inorganic composite coating is prepared from the following components by weight percent: 24-30% of silica sol with the SiO2 content of 30%, 16-20% of styrene-acrylic emulsion with the solid content of 40-48%, 40-48% of pigment and filler, 10-15% of water and 1-2% of adjuvant. The invention also discloses a preparation method of the composite coating. The environment-friendly organic-inorganic composite coating has the advantages of cheap raw material cost, simple preparation method, toxic substance in the whole preparation process and using process, and environmental friendliness. The prepared product coating has the advantages of the organic coating and the inorganic coating, is stable in performance, washing resistance and corrosion resistance and can be cured into a film under normal temperature and the film does not crack. The test shows that the performance index and the environment protection index are respectively in accordance with the national standard requirement and the coating has good application value.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

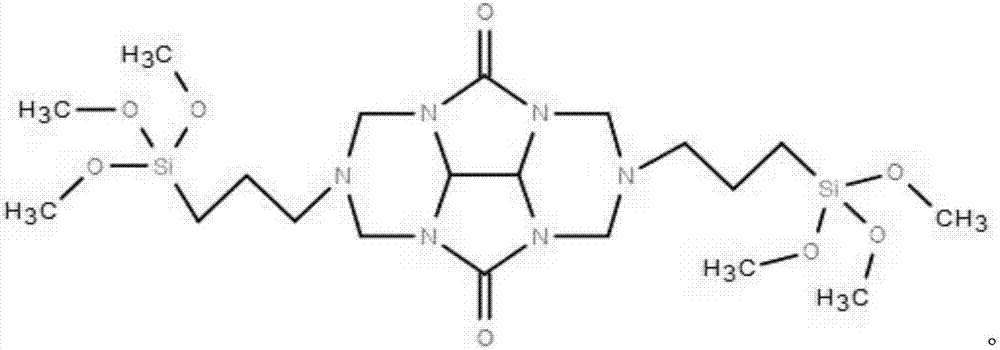

Two-component organosilicon pouring sealant and preparation method thereof

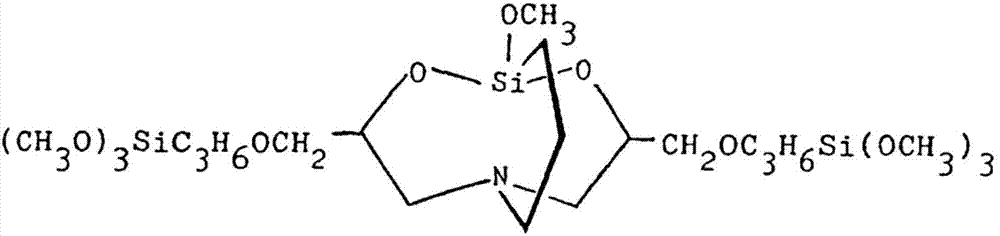

ActiveCN106947428AAdd lessDoes not affect liquidityNon-macromolecular adhesive additivesNitrogenSealant

The invention provides a two-component organosilicon pouring sealant. The two-component organosilicon pouring sealant comprises a component A and a component B with equal mass, wherein the component A comprises 100 parts of a base material, a platinum catalyst with the mass of platinum accounting for 1 to 500 ppm of the mass of the component A, and 1 to 5 parts of an adhesion promoter; the component B comprises 100 parts of a base material, 0.2 to 20 parts of a crosslinking agent and 0.002 to 0.5 part of an inhibitor; and the adhesion promoter is nitrogen heterocycle containing polycyclic siloxane. The invention belongs to the technical field of pouring sealants. The two-component organosilicon pouring sealant provided by the invention has the advantages of good flame-retardant performance, adhesion properties with a substrate, excellent fluidity, no poisoning caused by a platinum catalyst, environmental protection, safety, and easy operation.

Owner:广东皓明有机硅材料有限公司

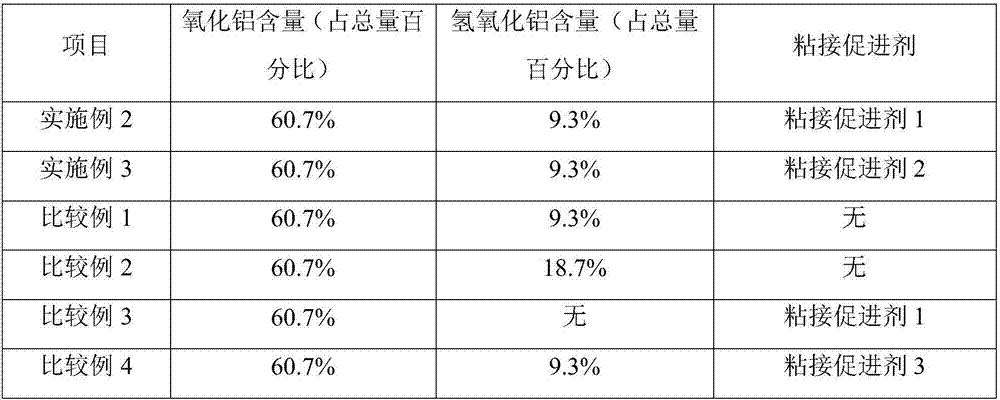

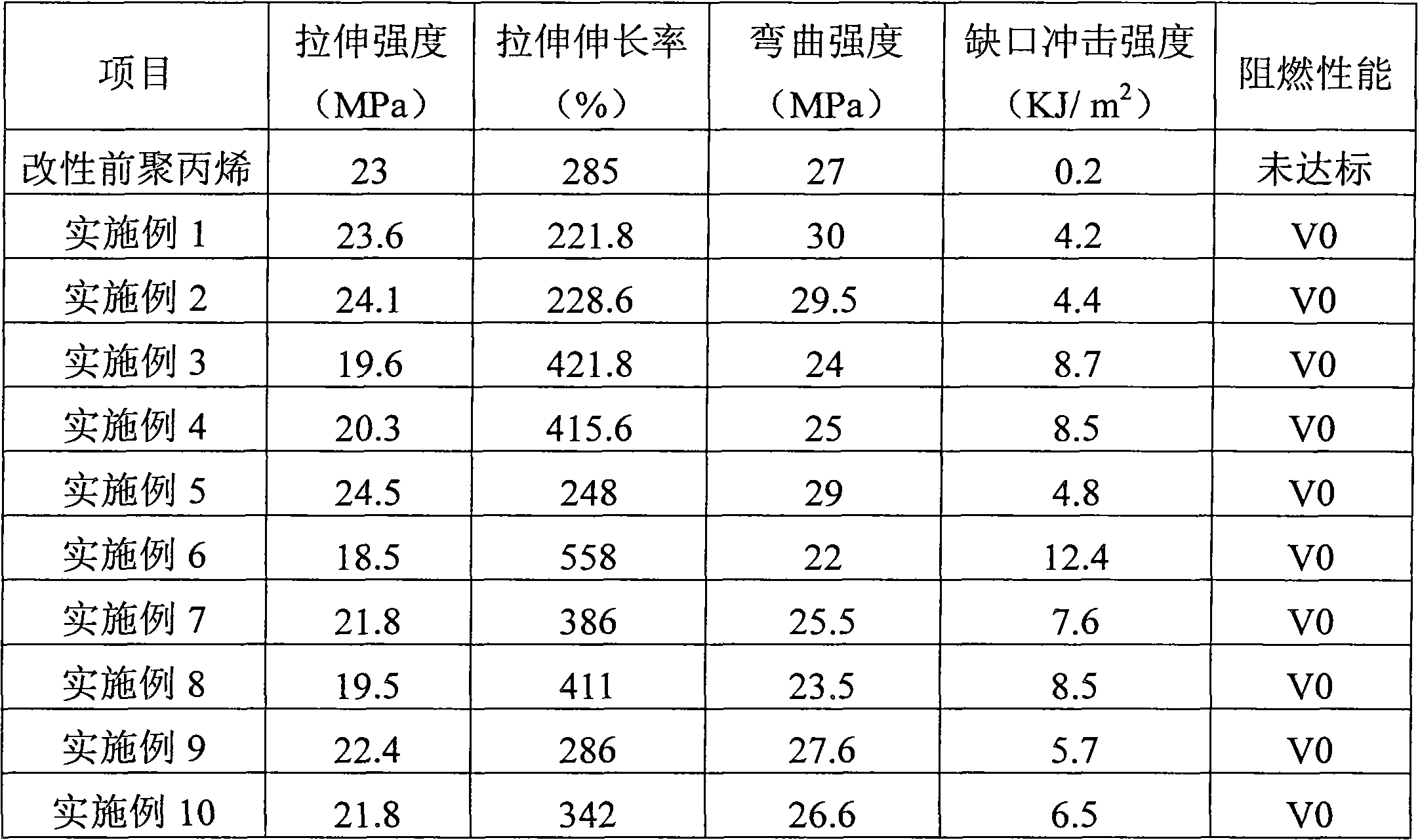

Fire-retarding and low-temperature resistant polypropylene material, preparation method thereof and use thereof

ActiveCN101974195AImprove flame retardant performanceReduce stretchPedestrian/occupant safety arrangementInsulated cablesThermoplastic elastomerFlexural strength

The invention discloses a fire-retarding and low-temperature resistant polypropylene material, a preparation method thereof and use thereof. The material consists of 50 to 75 weight parts of co-polypropylene, 15 to 25 weight parts of fire retardant, 10 to 25 weight parts of thermoplastic elastomer and 0.2 to 0.5 weight part of antioxygen. The preparation method comprises: mixing the components in a high-speed mixer; feeding the mixture in an double-screw extrude equipped with multistage heating zones; and uniformly dispersing, extruding to make grains, and obtaining the fire-retarding and low-temperature resistant polypropylene material. The fire resistance of polypropylene material reaches UL94-3.2mm V0, the polypropylene material can bear a temperature of -20DEG C, the tensile strength of the polypropylene material is over 18MPa, the tensile elongation of the polypropylene material is over 200 percent, and the bending strength of the polypropylene material is not less than 22MPa. The fire-retarding and low-temperature resistant polypropylene material can be used for making automobile safety cell, control wire twisted sleeve, various outdoor electric wire protective sleeves and the like.

Owner:合诚技术股份有限公司

Bronzing pulp and preparation method thereof

ActiveCN103255646BRich styleRich wash fastnessTransfer printing processDyeing processWater basedSolvent

The invention discloses bronzing pulp. The bronzing pulp is prepared from the following raw materials in parts by weight: 60-80 parts of acrylic ester emulsion, 2-6 parts of deionized water, 3-10 parts of a solvent, 1-5 parts of a stabilizer, 10-20 parts of EVA (Ethylene-Vinyl Acetate) hot melt adhesive powder, 0.5-3 parts of silica, 0.2-0.5 part of a polyurethane defoaming agent, 0.1-0.5 part of a pH regulator, 0.1-0.2 part of a preservative, 0.3-1 part of an emulsion wetting agent and 0.4-2 parts of a thickener. The bronzing pulp has the beneficial effects that the bronzing pulp is water-based pulp, the raw materials are easy to obtain and environment-friendly, the production is convenient, the technology is mature, and substances harmful to the environment can not be produced; and the bronzing pulp is soft in handfeel, firm in fastness, outstanding in resistance to tension fracture and diversified in application mode, enriches the styles of textiles, and endows the textiles with the noble quality.

Owner:GUANGZHOU SHENGQIN IND

Environment-friendly non-glue cotton

The invention provides environment-friendly non-glue cotton, comprising the following components in percentages by mass: 25-30% of cotton fiber, 50-65% of polyester fibers and 15-25% of corn fibers, wherein the cotton fibers are collagen coated cotton fibers, by utilizing the collagen, nutrients necessary for human skin can be given, affinity with a human body and comfortable sensation of the human body can be increased, and multiple healthcare functions are provided, so that the using performance and the social and economic benefits of the non-glue cotton are improved. The polyester fibers are modified by bamboo charcoal, so that a micro-porous structure is provided, the anti-static electricity capacity, the antibacterial ability and the anti-fungus capacity of the non-glue cotton are increased. The corn fibers have small specific gravity, the melting point is up to 175 DEG C, the moisture regain is lower, degradation products of the corn fibers are harmless lactic acid, carbon dioxide and water, toxic substances cannot be generated during combustion, and the corn fibers are novel environment-friendly fibers.

Owner:ANHUI LION GOOSE PROD

Flame retardant cushion of public bus seat

ActiveCN104369684AAvoid or reduce burns and burnsEasy to useBack restsThigh restsPolyesterNylon material

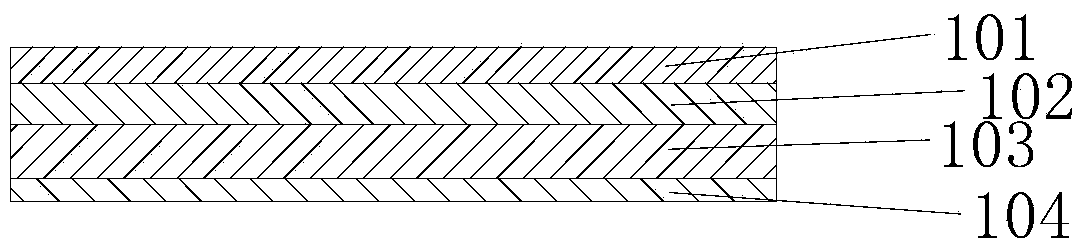

The invention discloses a flame retardant cushion of a public bus seat. The cushion comprises a human-contacted layer, a heat insulating layer, a counter-fire layer and an aluminum foil layer in sequence, wherein the human-contacted layer is woven by the following components, after being mixed, in parts by weight by a conventional method:10-30 parts of wear-resisting and flame-retarding fibers, and 70-90 parts of flame-retarding and fire-preventing fibers; the heat insulating layer is woven by the following components, after being mixed, in parts by weight by a conventional method: 0-30 parts of hollow three-dimensional crimp polyester staple fibers, and 70-100 parts of one of the following fibers: poly-aromatic oxadiazoles fibers and modacrylic chloride; and the counter-fire layer is woven by one or more fibers of flame retardant polyester, flame retardant nylons, flame retardant adhesive, modacrylic chloride, poly-aromatic oxadiazoles fibers, polysulfonamide, aramid fibers 1313, aramid fibers 1414 and pre-oxidized fibers. The flame retardant cushion is excellent in flame retardance, comfort and wear resistance.

Owner:中芳新材料有限公司 +1

Inflaming retarding cushion for bus chair

ActiveCN104228273AAvoid or reduce burns and burnsEasy to useStuffed mattressesSynthetic resin layered productsPolyesterInsulation layer

The invention discloses an inflaming retarding cushion for a bus chair. The inflaming retarding cushion successively comprises a layer in contact with people, a heat insulation layer, a counterfire layer and an aluminium foil layer, wherein the layer in contact with people is formed by blending the following components in parts by weight: 10-30 parts of abrasion-proof fire retardant fibers and 70-90 parts of inflaming retarding fireproof fibers, and weaving the blended components by a conventional method; the heat insulation layer is formed by blending the following components in parts by weight: 0-30 parts of hollow three-dimensional crimped polyester staple fibers, 70-100 parts of one of the following fibers of inflaming retarding vinylon and preoxidized fibers, and weaving the blended components by a conventional method; the counterfire layer is woven by one or multiple kinds of fibers of inflaming retarding polyester fibers, inflaming retarding nylon, inflaming retarding viscose, modacrylic fiber with chloride, aromatic oxadiazoles fibers, polysulfonamide, aramid fibers 1313, aramid fibers 1414 and preoxidized fibers. The inflaming retarding cushion has excellent flame retardance, comfort feeling and wear resistance.

Owner:中芳新材料有限公司 +1

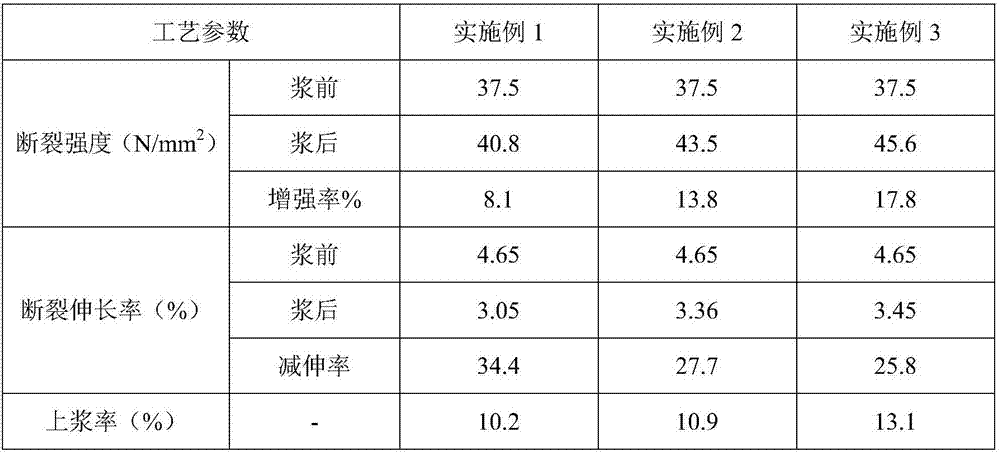

Environment-friendly wool textile yarn sizing agent and sizing technology

InactiveCN107237130AHigh strengthImprove toughnessBiochemical fibre treatmentAnimal fibresPolyvinyl alcoholEngineering

The invention belongs to the technical field of textile yarn sizing, and particularly relates to an environment-friendly wool textile yarn sizing agent and a sizing technology. Strength of sized yarn is remarkably improved, adhesion force of medium-temperature soluble starch to the wool textile is improved to a certain degree by the aid of nanometer titania and nano-zinc oxide, size film performance for starch is improved while antibacterial performance is improved, a size film is flexible and smooth and has high strength, toughness and adhesion force, and the yarn is good in wear resistance, stability and compatibility; without addition of PVA (polyvinyl alcohol), the sizing agent is environment-friendly, raw materials are easy to degrade, and desizing is easy; the technology is simple, environment-friendly and low in cost, and no toxic substances are produced.

Owner:太仓红桥服饰有限公司

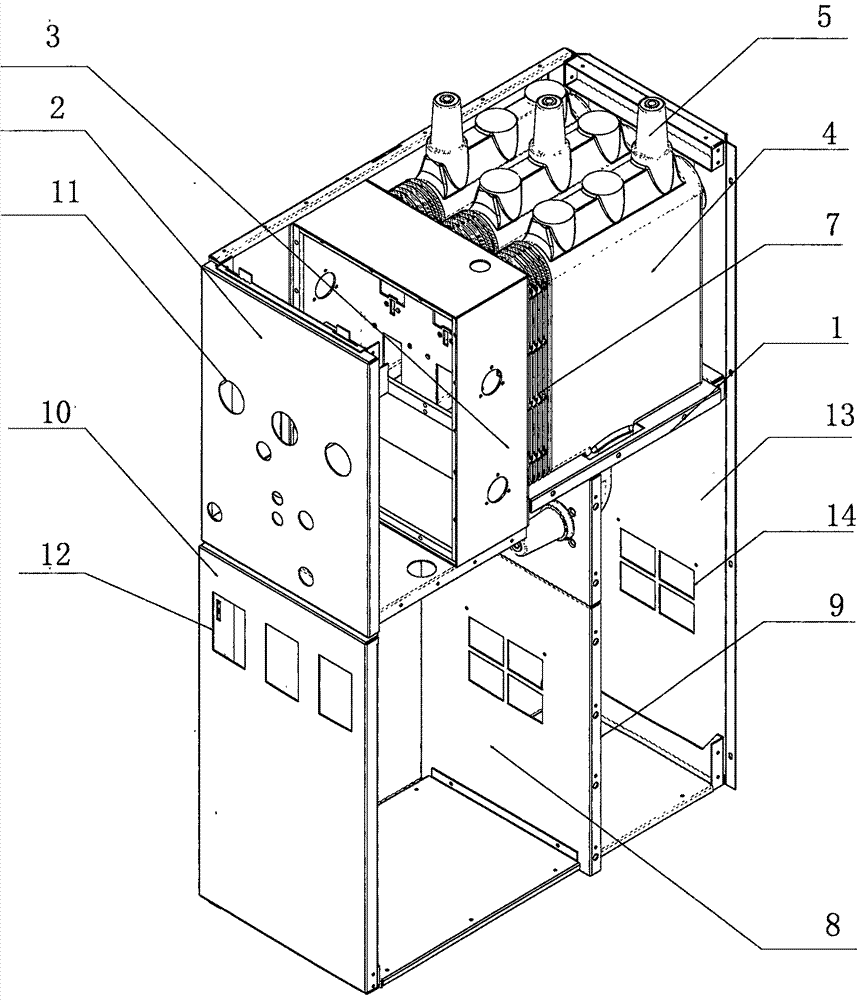

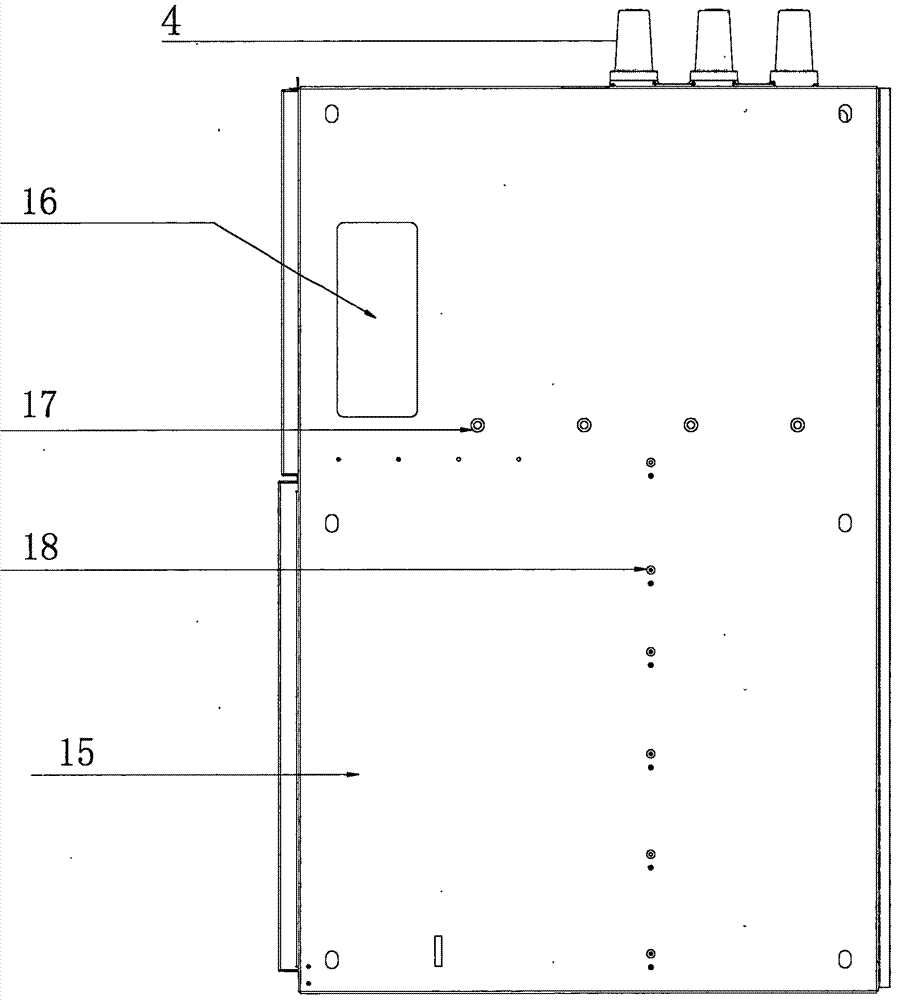

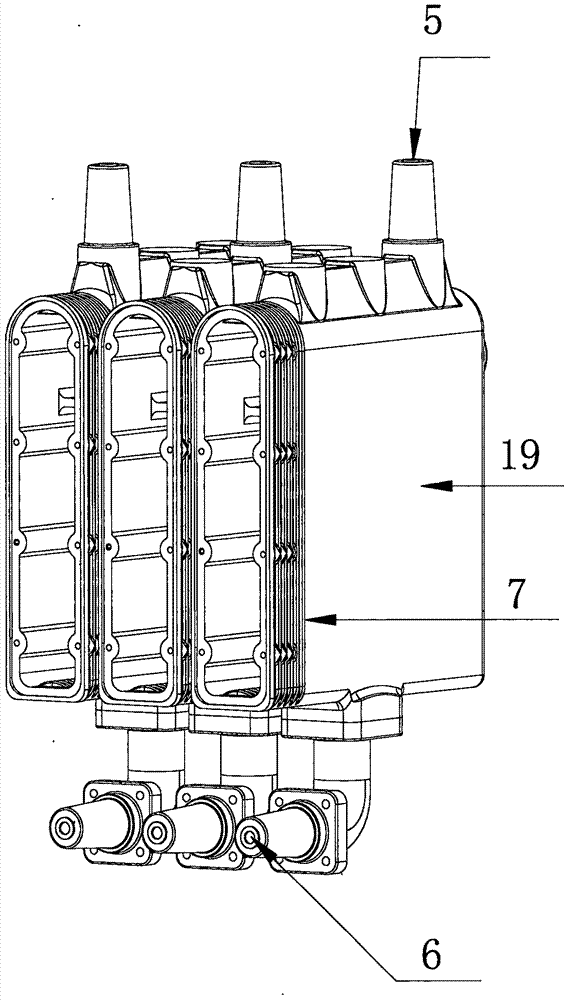

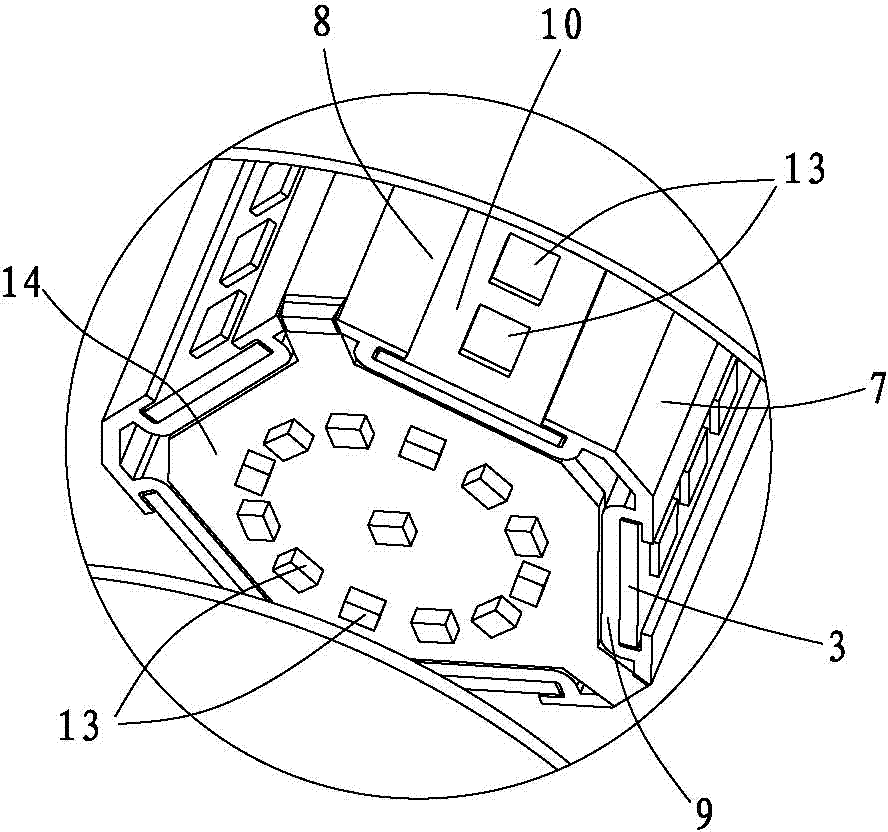

All-insulation solid ring network cabinet

PendingCN107359535AGood insulation performanceSafe and stable insulation performanceSwitchgear arrangementsEngineeringSurface plate

The present invention relates to an all-insulation solid ring network cabinet, which comprises a cabinet body formed by a transverse supporting plate, a longitudinal supporting plate, an upper panel and a lower panel. A mechanism box and a three-phase independent insulating barrel are arranged in the upper layer of the cabinet body. The top of the insulating barrel is provided with a bus sleeve. The lower end of the insulating barrel is provided with a lower outgoing sleeve. One side of the insulating barrel is provided with an umbrella ring. The umbrella ring is connected with the mechanism box. A cable chamber is arranged in the lower layer of the cabinet body. The upper panel on the front side of the cabinet body is provided with an isolation fracture. The back panel and the longitudinal supporting plate of the cabinet body are provided with a pressure releasing window. The lateral panel of the cabinet body is provided with an overhauling port. According to the invention, the all-insulation solid ring network cabinet adopts the composite insulating manner of the epoxy resin and the air-insulated, so that the all-insulation solid ring network cabinet is excellent, safe and stable in insulating performance. One side of the insulating barrel is provided with the umbrella ring, so that the insulating strength is increased. Based on the three-phase independent split design structure, the possibility of inter-phase short circuit is completely avoided. The all-insulation solid ring network cabinet is high in standardization degree, compact in structure, small in size, convenient in installation, strong in environment adaptability, environment-friendly and free of pollution.

Owner:YUEQING JIHUI POWER TECH

Green and flame-retardant cable filler

InactiveCN105419197AImprove flame retardant performanceDoes not produce toxic substancesEngineeringMagnesium stearate

Provided is a green and flame-retardant cable filler. The green and flame-retardant cable filler is prepared from the following raw materials, by weight, 16-32 parts of acrylic acid ester rubber microballoons, 8-14 parts of hydroquinone, 4-7 parts of zinc oxide, 5-8 parts of environmental protection thermal stabilizing agent, 6-17 parts of filling agent, 10-20 parts of magnesium hydroxide, 0.8-1.6 parts of AC foaming agent, 3-6 parts of magnesium stearate, 12-22 parts of nano graphene, 8-15 parts of graphite, 3-4 parts of oxidized polyethlene wax, 0.8-2.4 parts of curing accelerator, 6-13 parts of potassium nitrate, 4-7 parts of calcium stearate, 6-10 parts of sodium nitrite, 7-12 parts of sodium salicylate, and 5-8 parts of potassium sulfate. The beneficial effects are that the green and flame-retardant cable filler is advantaged by good flame retardant effects, high temperature resistance, low smoke, no generation of toxic substances, green and environmental protection.

Owner:王丽萍

A method for deep drying and water removal

ActiveCN103868330BEasy to vaporizeKeep dryDrying solid materials without heatToxic materialPollution

The invention provides a deep drying and dewatering method of solid materials. The method includes the following steps that firstly, drying reagents which are lower than water in polarity, surface tension and boiling point are fed into a container where dried objects are placed; secondly, after the drying reagents are fed in, the container is vacuumized; thirdly, inert gas with high purity and for drying is fed into the container to remove residual drying reagents. By means of competitive adsorption of the drying reagents and water on surfaces of dried materials, hydrone on the surfaces of the dried materials is displaced, accordingly, the drying effect on the solid materials is greatly improve, a better dewatering effect is realized, drying can be carried out more thoroughly, higher requirements for the drying effect of certain industries can be met, and especially production bottlenecks caused by the fact the requirement for water is very high in industries such as lithium electricity industry can be broken; according to the method, energy is saved, the environment is protected, toxic substances cannot be produced, and the method is free from pollution, environmentally friendly and efficient.

Owner:VIGOR GAS PURIFICATION TECHNOLOGIES (SUZHOU) CO LTD

Rattan processing agent for willow artworks

InactiveCN104441137AImprove anti-corrosion performanceImprove insect repellent effectWood treatment detailsReed/straw treatmentMedicineBaical Skullcap Root

The invention relates to a rattan processing agent for willow artworks, which comprises the following components: red ginseng, Chinese angelica, 5-10 parts of golden thread, baical skullcap root, corydalis tuber, tall gastrodia tuber, Chinese rhubarb, common anemarrhena rhizome, rhizoma kaempferiae, platycladi seeds, paraffin oil, glycerine, salicylic acid and water. The rattan processing agent provided by the invention is simple in manufacturing method, anti-corrosion and anti-insect capabilities of rattan processed by the processing agent are greatly upgraded, and the toughness of the rattan can be kept by drying after soaking so as to facilitate weaving.

Owner:FUNAN NATURE ARTS & CRAFTS

Lubricating oil used for bearings, and preparation method thereof

InactiveCN106010753AReduce frictionAvoid damageLubricant compositionToxic materialChlorinated paraffins

The invention discloses a lubricating oil used for bearings. The lubricating oil comprises, by weight, 60-75 parts of mineral base oil, 2-5 parts of zinc dithiosulfate, 8-10 parts of chlorinated paraffin, 6-8 parts of diallyl alkyl phosphate, 3-5 parts of hydroxyl silicone oil, 1-3 parts of diallylalkyl phosphate, 2-5 parts of polyalkoxy polyphenol, 4-9 parts of alkyl diphenylamine, 2-6 parts of butyloctyl diphenylamine, 5-12 parts of diethylene triamine penta(methylenephosphonic acid), 4-9 parts of dialkenyl succinimide, 10-15 parts of modified acrylic acid, 2-5 parts of sodium citrate, 3-6 parts of succinimide, 4-10 parts of chlorinated polyethylene, 10-14 parts of succinate ester, 12-20 parts of dodecenylsuccinic acid and 3-9 parts of anhydrous ethanol. Compared with lubricating oils in the prior art, the lubricating oil disclosed in the invention has the advantages of great reduction of the friction force of the bearings, reduction of damages of the bearings in the use process, reduction of temperature rising in the use process, prolong of the service life of the bearings, and realization of no generation of toxic substances in the use process, and can prolongs the life of the bearings by 60% or above.

Owner:ANHUI QIANSHAN BEARING MFG

Preparation method of chia ice cream

InactiveCN105360563AHigh in fatty acidsCholesterol freeFrozen sweetsFood ingredient functionsAdditive ingredientAntioxidant

The invention provides a preparation method of chia ice cream. The preparation method of chia ice cream includes: raw material treatment; raw material mixing; homogenization; sterilization; aging; freezing; and hardening. The ice cream prepared by the method is a pure natural food safe to eat, has high fatty acid content, is free of cholesterol, does not cause allergy, does not contain nutrient enriched marine pollutants, does not contain any ingredients harmful to the human body, also contains natural antioxidants, is not easy to rot and go bad, and does not produce toxic substances and peculiar smell. Also the chia ice cream has relatively high nutrient content, and the content of soluble dietary fiber is 12 times that of whole wheat bran. The chia ice cream can effectively enhance satiety, promote intestinal peristalsis and prevent constipation, and is an eating and health care integrated novel food suitable for people of all ages.

Owner:荣成恒顺海洋生物科技有限公司

Green degradable resin and production thereof

Green degradable resin and its production are disclosed. The resin consists of vegetable starch, fat polyester, plasticizer, compatibilizer, antioxidant and lubricant. The process is carried out by mixing vegetable starch with plasticizer form high-speed mixer, stirring for 10-20mins, laying aside for 1-2 day, preplasticizing mixture, adding mixture, fat polyester, compatibilizer, antioxidant and lubricant into double-screw extruder, melting and mixing from double-screw extruder, reacting and extruding, and obtaining the product. It achieves simple process, good performance and no environmental protection. It can be used fro disposable tableware, agricultural mulch film and packing bag.

Owner:TONGJI UNIV

Stable fire retardant coating

InactiveCN104212264AGood flame retardant effectImprove flame retardant performanceFireproof paintsConjugated diene hydrocarbon coatingsEmulsionFire retardant

The invention discloses a stable fire retardant coating which is prepared from the following raw materials in parts by weight: 4-10 parts of alkyl dimethyl benzyl ammonium salt type dodecyl dimethyl benzyl ammonium chloride, 5-7 parts of silicon oil, 15-25 parts of styrene-acrylic emulsion, 4-8 parts of tetrahydrofuran, 2-8 parts of antismoke agent, 3-7 parts of EPDM, 1-4 parts of paraffin, 4.5-7 parts of SBR latex rubber, 3-9 parts of nanometer titania, 4-8 parts of tribenzyl phenol polyoxyethylene ether and 2-5 parts of clay. The coating disclosed by the invention has good fire retardant efficiency, takes effective inflaming retarding effect at the early stage of a fire without generating toxic substances, and is healthy and environmentally-friendly.

Owner:QINGDAO BAOLIKANG NEW MATERIALS

Preparation method of golden minced shrimps

PendingCN113080432AEasy to operateReduce salt contentMeat/fish preservation by heatingAnimal scienceSalt content

The invention discloses a preparation method of golden minced shrimps. The method comprises the following steps: (1) preparing shrimp meat: selecting sea shrimps, shelling the heads, removing tails, and crushing the shrimps into paste; (2) preparing auxiliary materials: smashing dried shrimps for later use, and smashing garlic and onions for later use; (3) performing stir-frying to prepare golden minced shrimps; and (4) oil sealing, sterilization and preservation: after the product is boiled, enabling a layer of oil film to be formed on the surface of the finished product, preserving or putting the film into a high-temperature sterilization tank for high-temperature sterilization for 20 minutes at 110-121 DEG C, and then performing packaging and preservation. The minced shrimps prepared by the method can be prepared by using common cooking food materials without large-scale preparation processes such as centrifugation and fermentation, and the operation is simple; all the food materials and the auxiliary materials are added and decocted according to specific weight components and are sterilized and stored at high temperature, and the shelf life can reach 18 months; and the prepared golden minced shrimps are low in salt content, fermentation is avoided, toxic substances are not generated, and the taste and freshness of the product are improved by adding garlic and onions.

Owner:吴广为

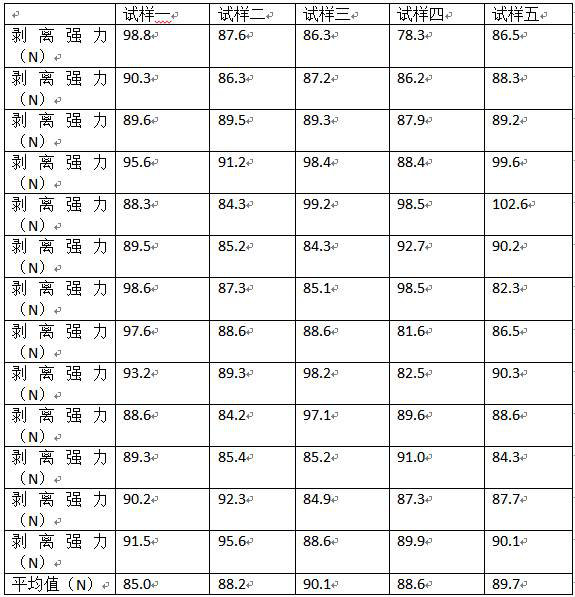

A fabric laminate of recycled modified PVB and its preparation method

ActiveCN112265330BImprove scratch resistanceGood flexibilitySynthetic resin layered productsLaminationPolymer sciencePlasticizer

Owner:YONGSHENG HAEIL DIFFERENTIAL FABRIC

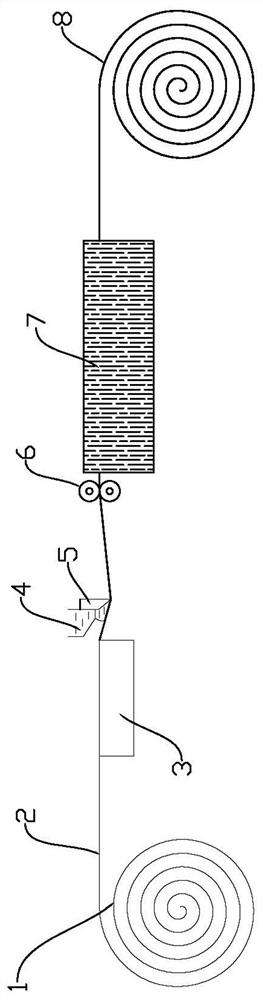

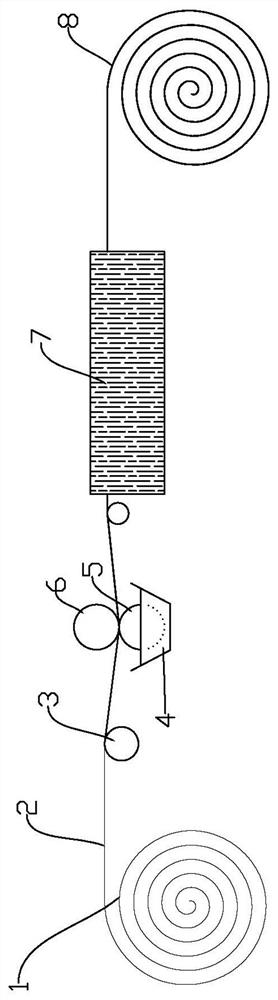

A kind of composite polymer coated fabric and its preparation method

ActiveCN110725135BChanging the properties of fugitive edgesGood flexibilityPretreated surfacesFurniture partsPolymer sciencePolymer coatings

The invention relates to a composite high-polymer coated fabric and a preparation method thereof. The composite high-polymer coated fabric comprises a base layer of the fabric and a composite high-polymer coating attached to at least one face of the base layer of the fabric; the composite high-polymer coated fabric further comprises a base melt layer which is 40-150 micrometers; the base melt layer refers to a composite structure formed by inserting a part of composite high-polymer coating into the base layer of the fabric during production; the thickness of the composite high-polymer coatingranges from 100 micrometers to 500 micrometers. By selection of the fabric base, selection of formula of the composite high-polymer coating and regulation of processing parameter, generation of the base melt layer is achieved, and thus, the product is superior to the prior art, in terms of fitting strength, hand feeling, fastness to yarn binding, and the like.

Owner:YONGSHENG HAEIL DIFFERENTIAL FABRIC

A kind of composite polymer laminated fabric and its preparation method

The invention relates to a composite polymer laminated fabric. Including fabric base material layer, base material melt glue layer, adhesive layer and composite polymer calendering layer, base material melt glue layer is composed of fabric base material layer of partial thickness, adhesive agent layer and composite polymer calendering layer of partial thickness A common composition; part of the adhesive layer and a partial thickness of the composite macromolecular calendering layer are embedded in the fabric tissue voids of the fabric substrate, thereby forming the substrate melting layer; the composite macromolecule component is made of EVA It is an essential component, and other components are added. The present invention enables the present invention to produce a base material melting glue layer through the selection of the fabric base material, the selection of the adhesive, and the improvement of the process parameters, and based on the base material melting glue layer, the present invention is compared with the existing The technology has made significant progress, especially in terms of the bonding fastness of the PVB layer, the feel after buckling, and the recovery of wrinkles.

Owner:YONGSHENG HAEIL DIFFERENTIAL FABRIC

Coating for furniture

InactiveCN109021827ALong term protectionExtended service lifePolyurea/polyurethane coatingsAcrylic resinToxic material

The invention discloses a coating for furniture, wherein the coating for furniture includes the following components in parts by weight: 16-29 parts of a fluorocarbon modified acrylic emulsion, 14-26parts of a polyurethane emulsion, 7-16 parts of zinc stearate, 13-27 parts of epoxidized polydibutene resin, 26-37 parts of castor oil, 10-26 parts of butyl etherified amino resin, 14-29 parts of acrylic resin, 21-29 parts of mica powder, 15-26 parts of talc powder and 17-26 parts of titanium dioxide. The coating disclosed by the invention is more environmentally friendly, does not produce toxic substances, and is more conducive to human body health.

Owner:SICHUAN AIYIJIA FURNITURE CO LTD

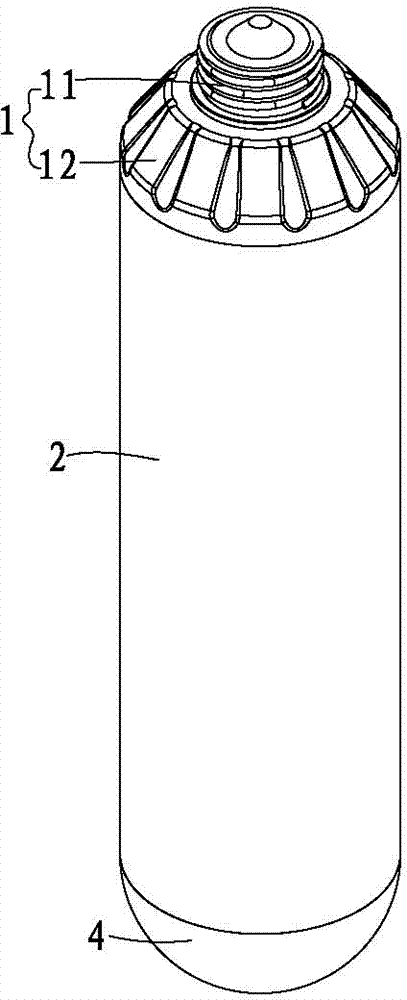

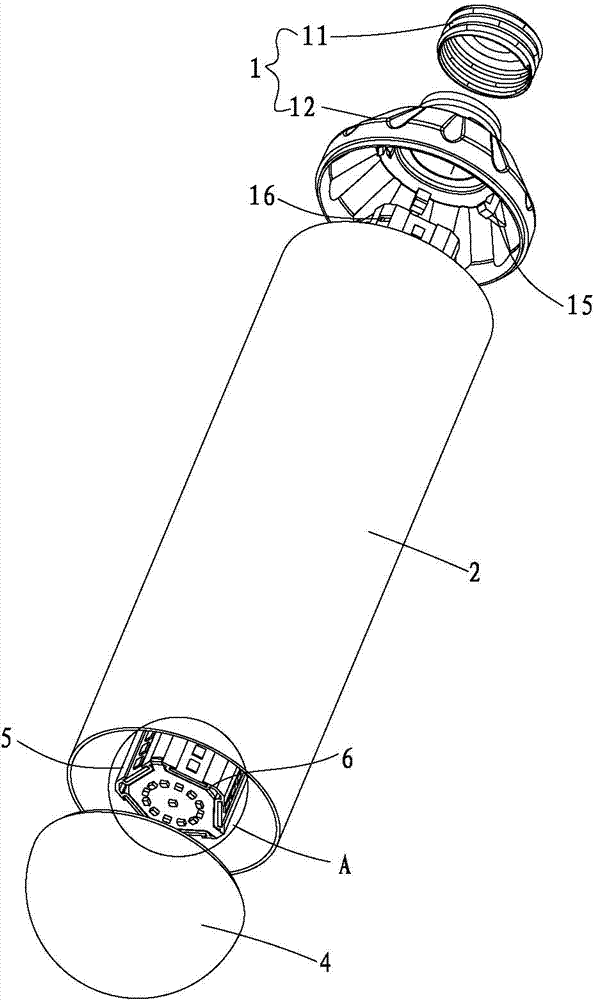

LED lamp

InactiveCN103791278ASimple structureAvoid breakingPoint-like light sourceElectric circuit arrangementsEngineeringToxic material

The invention belongs to the technical field of lighting and particularly relates to an LED lamp which comprises a lamp holder, a light expanding lamp tube, a light-emitting part and a lamp hood. The lamp holder and the lamp hood are fixedly connected with the upper end and the lower end of the light expanding lamp tube respectively. The lamp holder and the light-emitting part are detachably connected. The light-emitting part comprises at least three groove parts and at least three lamp plates. Each lamp plate is installed in the corresponding groove part. The LED lamp is simple in structure, the light expanding lamp tube is of an integrally formed structure made of plastics and is not prone to fracture, the lighting area is wider than that of an existing LED lamp and more importantly, fluorescent powder does not exist in the light expanding lamp tube, so that toxic substances will not be generated. In addition, the length and the width can be freely set.

Owner:DONGGUAN CITY SAIGANG DECORATION MATERIAL

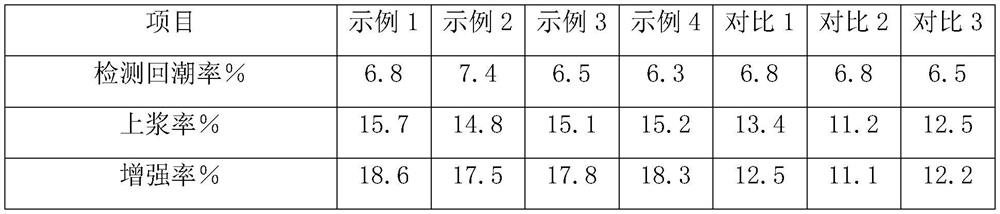

Sizing agent and sizing process for cotton yarn sizing

ActiveCN110952326BImprove cohesionImprove wear resistanceAbrasion resistant fibresVegetal fibresYarnProcess engineering

The invention relates to the technical field of yarn sizing, and specifically discloses a size and a sizing process for cotton yarn sizing. Wherein, the slurry is composed of the following components in parts by weight: 55-65 parts of modified starch CD-DF515, 10-20 parts of triethanolamine, 5-8 parts of dopamine grafted chitosan, 2-3 parts wax, 0.4-0.6 parts of antistatic agent BP; the sizing process utilizes double sizing machines to double-dip and double-roll warp yarns, and each sizing tank is filled with sizing after the sizing process is completed, and the viscosity of the sizing is 8.0 Pa•s~9.0Pa•s, slurry tank temperature 90℃~95℃, vehicle speed 50m / min~60m / min, grouting pressure 15KN~25KN, moisture regain 6.5%~7.5%. The invention has good sizing effect and long-lasting effect, can greatly improve the cohesive force, wear resistance and strength of sizing yarns, significantly reduce the number of warp stops and weft stops, and is more conducive to weaving.

Owner:JINJIANG YIXINGLONG TEXTILE IND

Novel environment-friendly building brick and preparation method

ActiveCN103664108BDoes not produce toxic substancesIncrease morning intensitySolid waste managementBrickThermal insulation

The invention relates to a novel environment-friendly building brick and a preparation method, and belongs to the technical field of waste disposal. The building brick comprises silicate cement, gypsum, a GCY activating agent, an MSZ168-C additive, coarse slag, fine slag and magnetized water. The preparation method comprises steps as follows: firstly, slag discharged by a slag waste incineration power plant is subjected to a series of pretreatment of hydrolytic tank washing, crushing screening, magnetic separation, flotation separation and screening of 3-15 cm particles, the slag and the MSZ168-C additive are added into an agitation tank by using a forced mixer according to a set proportion, the GCY activating agent is diluted in the magnetized water magnetized by a magnetizer, the mixture and cement are jointly added for agitation, and maintenance is performed after compression molding, so that a finished product is obtained. According to the novel environment-friendly building brick and the preparation method, the slag is prepared into a mold brick without firing, the preparation time is shortened, the burning energy consumption is reduced, emission of harmful gas in a burning process is avoided, and the environment protection effect is remarkable; and the manufactured brick is high in strength, light in weight and good in thermal insulation property, and the requirement for light mass, energy conservation and thermal insulation of wall materials of a modern building can be met.

Owner:山东环兴再生资源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com