All-insulation solid ring network cabinet

A ring network cabinet, fully insulated technology, applied in the direction of switchgear, electrical components, switchgear settings, etc., can solve the problems of high aging degree of equipment, large size, limited use occasions, etc., to achieve safe and stable insulation performance and environmental adaptation. The effect of strong performance and convenient mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

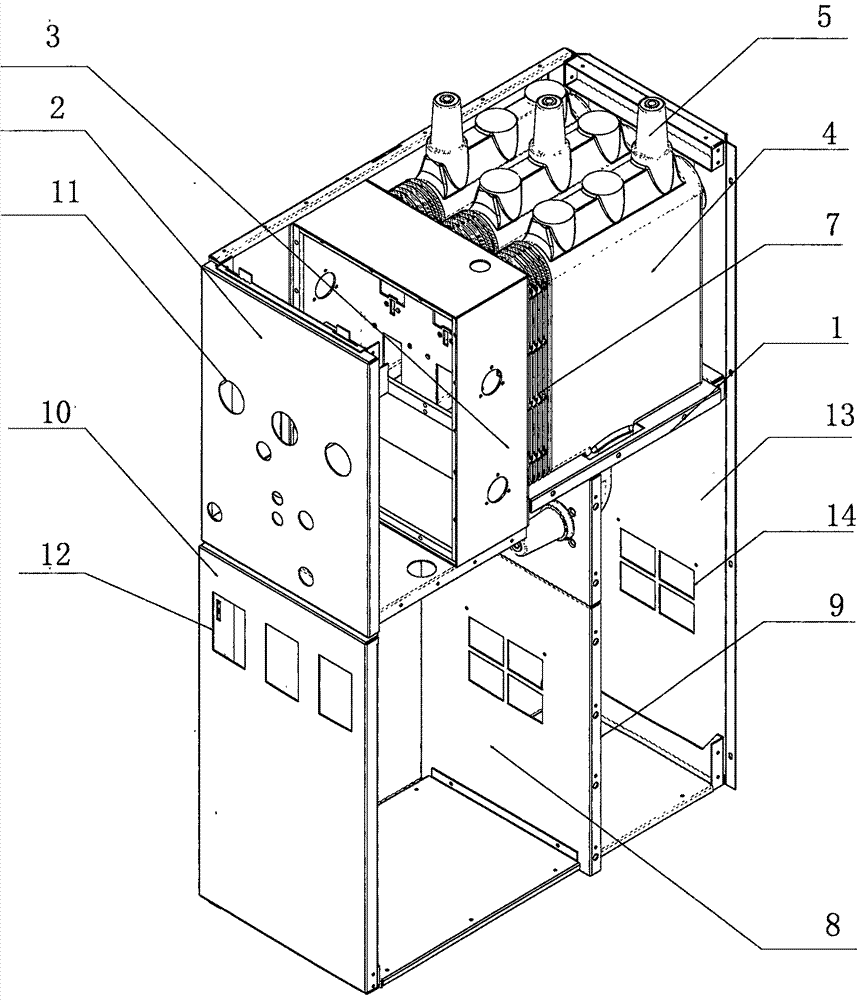

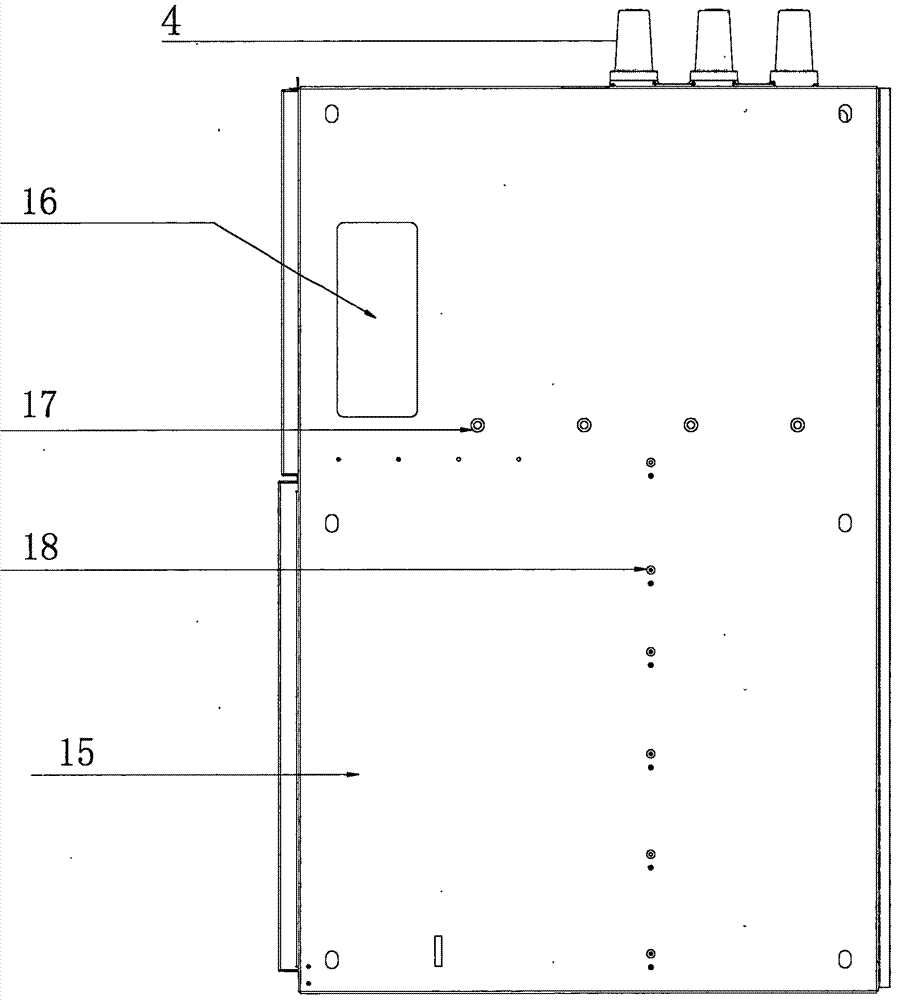

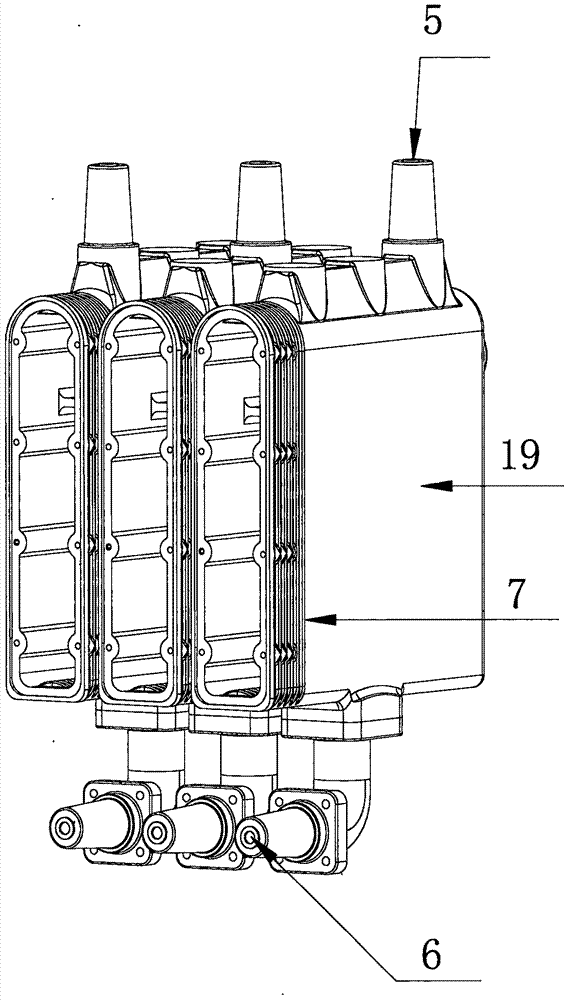

[0020] refer to figure 1 , figure 2 with image 3 , the present invention includes a cabinet body composed of a transverse support plate 1, a longitudinal support plate 9, an upper panel 2, and a lower panel 10. The cabinet is divided into upper and lower layers. The upper cabinet is provided with a mechanism box 3 and a three-phase independent insulating cylinder 4 . A busbar bushing 5 is arranged on the top of the insulating cylinder 4 . The lower end of the insulating cylinder 4 is provided with a lower outlet sleeve 6 . An umbrella ring 7 is arranged on one side of the insulating cylinder 4 . The umbrella ring 7 is connected to the mechanism box 3 . A 5mm thick oblong silicone sealant is arranged on the connecting surface of the umbrella ring 7 . A 5mm silicone seal is set on the connection surface of the mechanism box 3 . The lower cabinet is provided with a cable compartment 8 . An isolation fracture 11 is arranged on the upper panel 2 of the front of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com