Novel environment-friendly building brick and preparation method

A construction and environmental protection technology, applied in the field of waste treatment, can solve the problems of soil and groundwater safety hazards, occupation of land resources, etc., achieve outstanding environmental protection effects, reduce combustion energy consumption, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

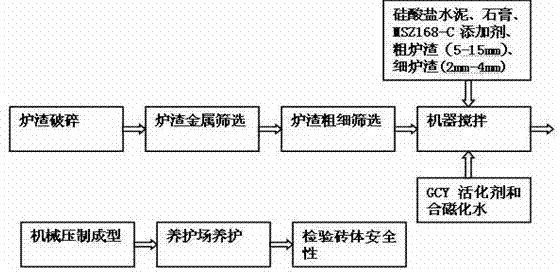

Method used

Image

Examples

Embodiment 1

[0067] Environmentally friendly building bricks consist of the following components in parts by weight:

[0068] Portland cement: 3 parts

[0069] Gypsum: 5 parts

[0070] GCY Activator: 1 part

[0071] MSZ168-C additive: 10 parts

[0072] Coarse slag (5-15mm): 40 parts

[0073] Fine slag (2mm-4mm): 20 parts

[0074] Magnetized water: 3 parts

[0075] The method for environmental protection building brick, comprises the steps:

[0076] (1) Slag treatment

[0077] a. The slag discharged from the waste incineration power plant is washed by the hydrolysis tank to remove the soluble salt;

[0078] b. Crushing and screening to adjust the size distribution of slag particles;

[0079] c. Magnetic separation to remove iron;

[0080] d. Carry out buoyancy sorting to remove remaining non-ferrous metals;

[0081] e. Screen 3-15mm granules for later use, and 3mm and less granules and water roll milling, stirring, aging, and later use;

[0082] (2) Raw material ratio and mixing ...

Embodiment 2

[0090] Environmentally friendly building bricks consist of the following components in parts by weight:

[0091] Portland cement: 8 parts

[0092] Gypsum: 10 parts

[0093] GCY activator: 5 parts

[0094] MSZ168-C additive: 20 parts

[0095] Coarse slag (5-15mm): 50 parts

[0096] Fine slag (2mm-4mm): 30 parts

[0097] Magnetized water: 8 parts;

[0098] The method for environmental protection building brick, comprises the steps:

[0099] (1) Slag treatment

[0100] a. The slag discharged from the waste incineration power plant is washed by the hydrolysis tank to remove the soluble salt;

[0101] b. Crushing and screening to adjust the size distribution of slag particles;

[0102] c. Magnetic separation to remove iron;

[0103] d. Carry out buoyancy sorting to remove remaining non-ferrous metals;

[0104] e. Screen 3-15mm granules for later use, and 3mm and less granules and water roll milling, stirring, aging, and later use;

[0105] (2) Raw material ratio and mixi...

Embodiment 3

[0113] Environmentally friendly building bricks consist of the following components in parts by weight:

[0114] Portland cement: 5 parts

[0115] Plaster: 7 parts

[0116] GCY activator: 2.5 parts

[0117] MSZ168-C additive: 15 parts

[0118] Coarse slag (5-15mm): 45 parts

[0119] Fine slag (2mm-4mm): 25 parts

[0120] Magnetized water: 5 parts;

[0121] The method for environmental protection building brick, comprises the steps:

[0122] (1) Slag treatment

[0123] a. The slag discharged from the waste incineration power plant is washed by the hydrolysis tank to remove the soluble salt;

[0124] b. Crushing and screening to adjust the size distribution of slag particles;

[0125] c. Magnetic separation to remove iron;

[0126] d. Carry out buoyancy sorting to remove remaining non-ferrous metals;

[0127] e. Screen 3-15mm particles for later use, 3mm and less than 3mm particles;

[0128] (2) Raw material ratio and mixing

[0129] a. Using a magnetizer to magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com