Sizing agent and sizing process for cotton yarn sizing

A cotton yarn and sizing technology, which is applied in the field of sizing and sizing technology for cotton yarn sizing, can solve the problems of increasing production costs of printing and dyeing enterprises, insufficient sizing strength of starch sizing, and large environmental pollution. The raw material is easy to degrade, the surface hairiness is protected, and the effect of environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

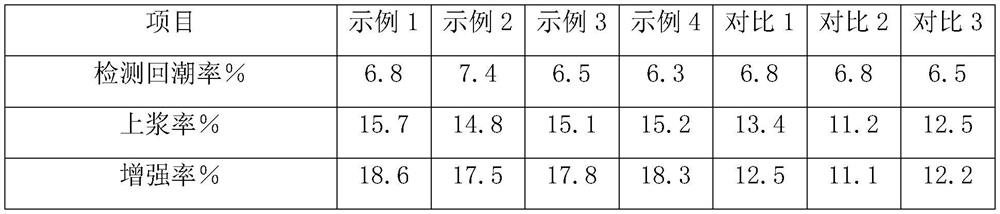

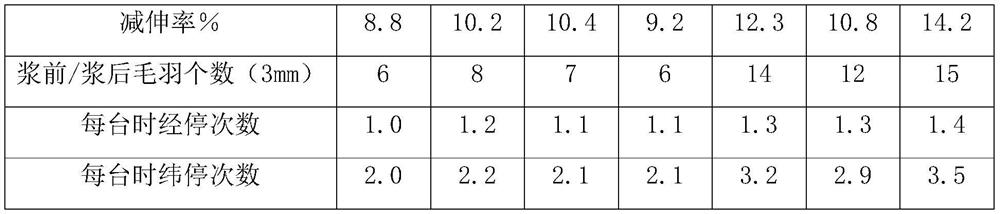

Examples

Embodiment 1

[0021] This embodiment provides a kind of size for cotton yarn sizing, which is composed of the following components in parts by weight: 60 parts of modified starch CD-DF515, 15 parts of triethanolamine, 8 parts of dopamine grafted chitosan Sugar, 2 parts of wax, 0.5 parts of antistatic agent BP.

[0022] The cotton yarn sizing process using the slurry of this embodiment includes a sizing process and a sizing process, and the sizing process is specifically: taking the dopamine-grafted chitosan of the stated parts by weight and dissolving it in deionized water , dripping sodium hydroxide solution to adjust the pH value of the solution to 7.5, to obtain a dopamine grafted chitosan solution; In the sugar solution, conduct airtight ultrasonic treatment for 23 minutes, then pour it into the mixing tank and stir for 75 minutes at a constant temperature of 90°C, the stirring speed is 300r / min, add the wax and triethanolamine in the parts by weight during the stirring and heating proc...

Embodiment 2

[0025] This embodiment provides a kind of size for cotton yarn sizing, which is composed of the following components in parts by weight: 55 parts of modified starch CD-DF515, 18 parts of triethanolamine, 5 parts of dopamine grafted chitosan Sugar, 2 parts of wax, 0.4 parts of antistatic agent BP.

[0026] The cotton yarn sizing process using the slurry of this embodiment includes a sizing process and a sizing process, and the sizing process is specifically: taking the dopamine-grafted chitosan of the stated parts by weight and dissolving it in deionized water , drop sodium hydroxide solution to adjust the pH value of the solution to 7.8 to obtain a dopamine grafted chitosan solution; In the sugar solution, conduct airtight ultrasonic treatment for 30 minutes, then pour it into the mixing tank and stir for 60 minutes at a constant temperature of 95°C, the stirring speed is 300r / min, add the wax and triethanolamine in the parts by weight during the stirring and heating process; ...

Embodiment 3

[0029] This embodiment provides a kind of size for cotton yarn sizing, which is composed of the following components in parts by weight: 65 parts of modified starch CD-DF515, 20 parts of triethanolamine, 6.5 parts of dopamine grafted chitosan Sugar, 3 parts of wax, 0.6 parts of antistatic agent BP.

[0030] The cotton yarn sizing process using the slurry of this embodiment includes a sizing process and a sizing process, and the sizing process is specifically: taking the dopamine-grafted chitosan of the stated parts by weight and dissolving it in deionized water , dripping sodium hydroxide solution to adjust the pH value of the solution to 7.5, to obtain a dopamine grafted chitosan solution; In the sugar solution, conduct airtight ultrasonic treatment for 25 minutes, then pour it into the mixing tank and stir for 65 minutes at a constant temperature of 90°C, the stirring speed is 400r / min, add the wax and triethanolamine in the parts by weight during the stirring and heating pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com