A fabric laminate of recycled modified PVB and its preparation method

A fabric layer and laminate technology, applied in the field of recycled modified PVB laminated fabric and its preparation, can solve the problems of harsh production environment, low bonding strength, complicated production process, etc., and achieves soft hand feel and good weather resistance. , Good scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

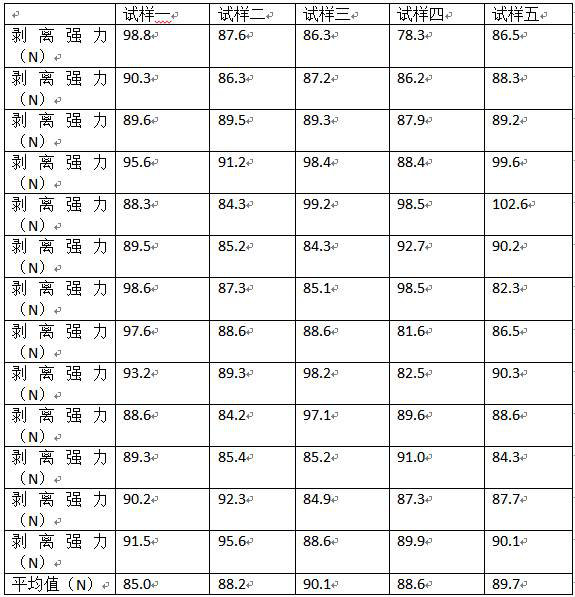

Examples

Embodiment 1

[0048] A fabric laminate of recycled modified PVB, the laminate comprises a fabric layer and a modified PVB layer compounded on one surface of the fabric layer, the thickness of the modified PVB layer is 1.2 mm. In this embodiment, the fabric substrate is made of polyester yarn through a plain weaving process.

[0049] The preparation method of the fabric laminate of above-mentioned recovery modified PVB is as follows:

[0050] S1, the fabric layer is treated with corona equipment first, so that the surface energy of the fabric layer decreases, and the adhesion with the PVB layer is enhanced;

[0051] S2, 50kg of calcium carbonate was surface-treated with 1.8kg of vinyltriethoxysilane, specifically calcium carbonate and vinyltriethoxysilane were mixed and dispersed in a high-speed mixer for 5 minutes;

[0052] S3. Start the internal mixer, and after the temperature rises to 50°C, put 60kg of recycled PVB into the feeding port, and mix the rubber for 3 minutes; IRGAFOS 168 an...

Embodiment 2

[0055] A fabric laminate of recycled modified PVB, the laminate comprises a fabric layer and a modified PVB layer compounded on one surface of the fabric layer, and the thickness of the modified PVB layer is 1.0mm. In this embodiment, the fabric substrate is made of polyester yarn through a plain weaving process.

[0056] The preparation method of the fabric laminate of above-mentioned recovery modified PVB is as follows:

[0057] S1, the fabric layer is treated with corona equipment first, so that the surface energy of the fabric layer decreases, and the adhesion with the PVB layer is enhanced;

[0058] S2. Surface treatment of 50 kg of calcium carbonate with 1.6 kg of methacryloxytrimethoxysilane, specifically mixing and dispersing calcium carbonate and methacryloxytrimethoxysilane in a high-speed mixer for 5 minutes;

[0059] S3. Start the internal mixer, and after the temperature rises to 50°C, put 50kg of recycled PVB into the feeding port, and mix the rubber for 5 minut...

Embodiment 3

[0062] A fabric laminate of recycled modified PVB, the laminate comprises a fabric layer and a modified PVB layer compounded on one surface of the fabric layer, and the thickness of the modified PVB layer is 0.8mm. In this embodiment, the fabric substrate is made of polyester yarn through a plain weaving process.

[0063] The preparation method of the fabric laminate of above-mentioned recovery modified PVB is as follows:

[0064] S1, the fabric layer is treated with corona equipment first, so that the surface energy of the fabric layer decreases, and the adhesion with the PVB layer is enhanced;

[0065] S2, 50kg of calcium carbonate is surface-treated with 1.2kg of aminopropyltrimethoxysilane, specifically calcium carbonate and aminopropyltrimethoxysilane are mixed and dispersed in a high-speed mixer for 5 minutes;

[0066] S3. Start the internal mixer, and after the temperature rises to 50°C, put 70kg of recycled PVB into the feeding port, and mix the rubber for 5 minutes; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com