Flame retardant cushion of public bus seat

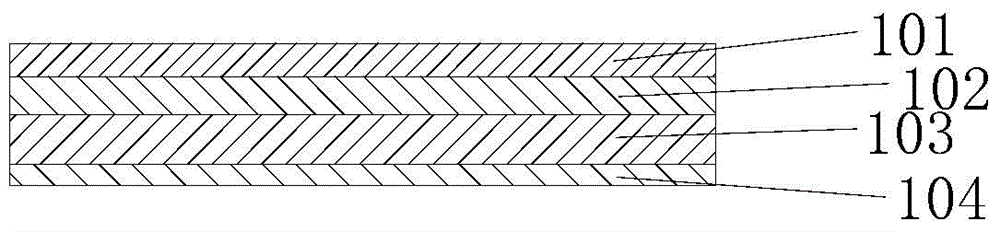

A seat and back cushion technology, which is applied in the field of bus seat flame retardant back cushions, can solve the problems of a large amount of smoke hydrogen halide gas produced by halogen-containing flame retardant materials, secondary hazards, etc., to reduce burns and burns, good flame retardant effect, durable Good high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 and the preparation of human contact layer

[0054] Take each raw material by the data of embodiment 1 in table 1, mix uniformly, loosen and pre-treat, card into raw sliver on carding machine; Combine mature sliver on drawing frame again; Carry out drafting and adding on roving frame Twisting, further drafting and twisting on the spinning frame to make blended yarn, the yarn linear density is 30tex. Then the blended yarn is woven into a plain weave structure with a large circular machine weft knitting method, with a grammage of 180g / m 2 , which is the human-contact layer of Example 1.

[0055] Table 1 Raw material composition list of the contact layer with people (unit: kg)

[0056]

[0057] The flame-retardant polyester in Table 1 was purchased from Shanghai Defulun Chemical Fiber Co., Ltd.; the flame-retardant nylon was purchased from EMS Swiss Chemical (China) Co., Ltd.; the aramid 1414 was purchased from DuPont, USA.

Embodiment 2

[0058] Embodiment 2 and the preparation of human contact layer

[0059] Each raw material was weighed according to the data of Example 2 in Table 1, and the human contact layer of Example 2 was prepared according to the method described in Example 1.

Embodiment 3

[0060] Embodiment 3 and the preparation of human contact layer

[0061] Each raw material was weighed according to the data of Example 3 in Table 1, and the human contact layer of Example 3 was prepared according to the method described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com