Environment-friendly wool textile yarn sizing agent and sizing technology

A wool and fabric technology, applied in the field of textile yarn sizing, can solve the problems of increasing the production cost of printing and dyeing enterprises, insufficient sizing strength of starch sizing, large environmental pollution, etc., and achieves low cost, easy desizing and environment-friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

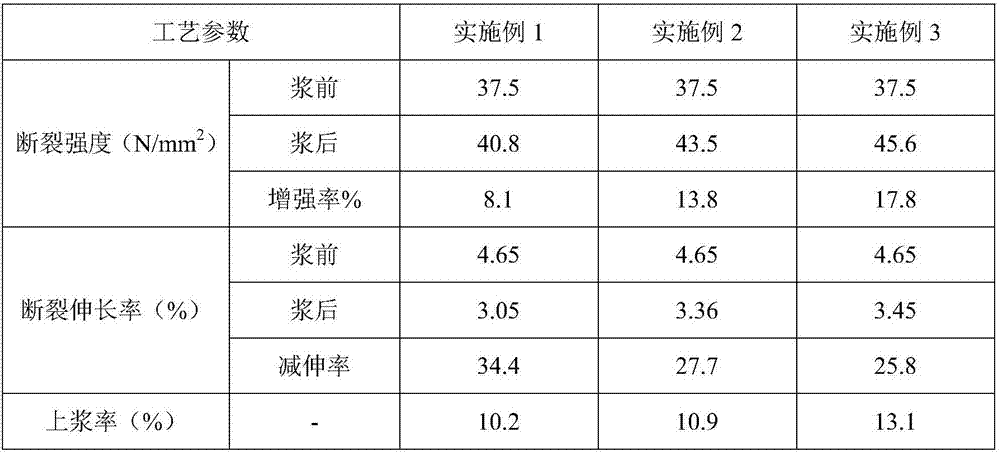

Embodiment 1

[0018] An environment-friendly wool fabric yarn size, comprising the following components in parts by weight: 8 parts of modified polyacrylate, 10 parts of medium-temperature soluble starch, 10 parts of polyvinyl alcohol, 2 parts of nano-zinc oxide, and 2 parts of nano-titanium dioxide.

[0019] It also includes 2 parts of auxiliary agent; the auxiliary agent is montmorillonite k10; the particle size of the auxiliary agent is less than 100nm.

[0020] Also includes 6 parts of synergist; said synergist is BP-A synergist, purchased from Changzhou Fengyuan Textile Auxiliaries Co., Ltd.

[0021] The modified polyacrylate is a silicone-modified polyacrylate emulsion, which is obtained by adding organosiloxane monomer to the acrylate emulsion and modifying it by ultrasonic vibration. The mass ratio of acrylate emulsion:organosiloxane monomer is is 10:1.

[0022] The medium temperature soluble starch is potato starch.

[0023] The slurry of the present invention is used for the siz...

Embodiment 2

[0029] An environmentally friendly wool fabric yarn size, comprising the following components in parts by weight: 12 parts of modified polyacrylate, 20 parts of medium-temperature soluble starch, 20 parts of polyvinyl alcohol, 3 parts of nano-zinc oxide, and 3 parts of nano-titanium dioxide.

[0030] It also includes 8 parts of auxiliary agent; the auxiliary agent is montmorillonite k10; the particle size of the auxiliary agent is less than 100nm.

[0031] Also includes 8 parts of synergist; said synergist is BP-A synergist, purchased from Changzhou Fengyuan Textile Auxiliaries Co., Ltd.

[0032] The modified polyacrylate is a silicone-modified polyacrylate emulsion, which is obtained by adding organosiloxane monomer to the acrylate emulsion and modifying it by ultrasonic vibration. The mass ratio of acrylate emulsion:organosiloxane monomer is is 10:1.

[0033] The medium temperature soluble starch is corn starch.

[0034] Above-mentioned a kind of size is used for the sizin...

Embodiment 3

[0040] An environment-friendly wool fabric yarn size, comprising the following components in parts by weight: 10 parts of modified polyacrylate, 15 parts of medium temperature soluble starch, 15 parts of polyvinyl alcohol, 2.5 parts of nano-zinc oxide, and 2.5 parts of nano-titanium dioxide.

[0041] It also includes 5 parts of auxiliary agent; the auxiliary agent is montmorillonite k10; the particle size of the auxiliary agent is less than 100nm.

[0042] Also includes 7 parts of synergist; said synergist is BP-A synergist, purchased from Changzhou Fengyuan Textile Auxiliaries Co., Ltd.

[0043] The modified polyacrylate is a silicone-modified polyacrylate emulsion, which is obtained by adding organosiloxane monomer to the acrylate emulsion and modifying it by ultrasonic vibration. The mass ratio of acrylate emulsion:organosiloxane monomer is is 10:1.

[0044] The medium temperature soluble starch is tapioca starch.

[0045] Above-mentioned a kind of size is used for the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com