Nano hybrid material modified organosilicone heat-conductive electronic pouring sealant and preparation method of sealant

A nano-hybrid material, silicone technology, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of poor fluidity, poor fluidity, insufficient fluidity, etc., to achieve good filling and dispersion, excellent Thermal conductivity, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 200 parts by weight of aluminum nitride and add it into a high-speed kneader, slowly add 1 part by weight of Y-methacrylphthaloxypropyltrimethoxysilane diluted with ethanol alcohol solution in advance under the condition of high-speed stirring, dropwise After completion, raise the temperature to 70°C and continue stirring at high speed for 2 hours, discharge the material, place the obtained filler in a vacuum drying oven to remove residual water and ethanol, and sieve to obtain Y-methacrylphthalein oxide with an average particle size of 2.5m. Aluminum nitride surface treated with propyltrimethoxysilane.

[0029] Weigh 200 parts by weight of aluminum oxide and add it into a high-speed kneader, slowly add 1 part by weight of Y-methacrylphthaloxypropyltrimethoxysilane diluted with ethanol alcohol solution in advance under the condition of high-speed stirring, drop After the addition is complete, raise the temperature to 70°C and continue stirring at high speed for 2 ...

Embodiment 2

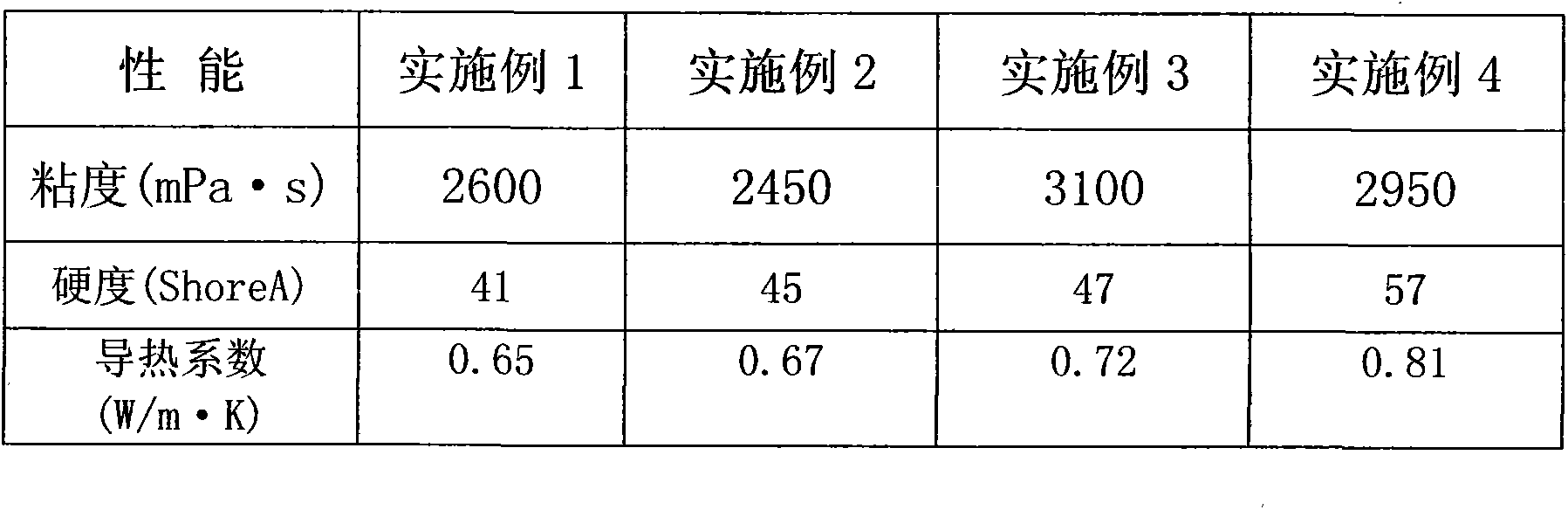

[0034] The preparation method and conditions of the heat-conducting silicone electronic potting compound modified by the nano-hybrid material of the present invention are as in Example 1, the viscosity is increased to 15 parts by weight of the liquid organic-silicon nano-hybrid material with a viscosity of 600mPa·s, and the corresponding The hydrogen-containing silicone oil crosslinking agent with a hydrogen content of 0.3% remained unchanged, and a modified heat-conducting silicone electronic potting adhesive was prepared. The performance test results are shown in Table 1. It can be seen that increasing the content of liquid organosilicon nano-hybrid material in an appropriate range is beneficial to the improvement of the fluidity of the heat-conducting potting compound, but has little effect on other properties.

Embodiment 3

[0036]The preparation method and conditions of the heat-conducting silicone electronic potting compound modified by nano-hybrid materials of the present invention are as in Example 1, and the vinyl polydimethylsiloxane is changed to a viscosity of 1200mPa "s and a vinyl content of 0.40 Wt% straight-chain vinyl polydimethylsiloxane, correspondingly change the hydrogen-containing silicone oil crosslinking agent with a hydrogen content of 0.3% to 5.9 parts by weight, the weight part of the organosilicon nano-hybrid material remains unchanged, and the viscosity decreases is 400mPa s, and the modified heat-conducting silicone electronic potting glue is obtained, and the performance test results are shown in Table 1. It can be seen that, compared with Examples 1 and 2, the thermal conductivity and viscosity of the potting glue do not change. big.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com