Warp and weft forwards and backwards entwisted interwoven impregnated core fabric for conveyor belt

A technology of positive and negative twisting, warp and weft, which is applied in the direction of textile, fabric, textile and papermaking, etc., can solve the problems of conveyor belt not running normally, affecting engineering, deviation, etc., to achieve long service life, prolong service life and fastness strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

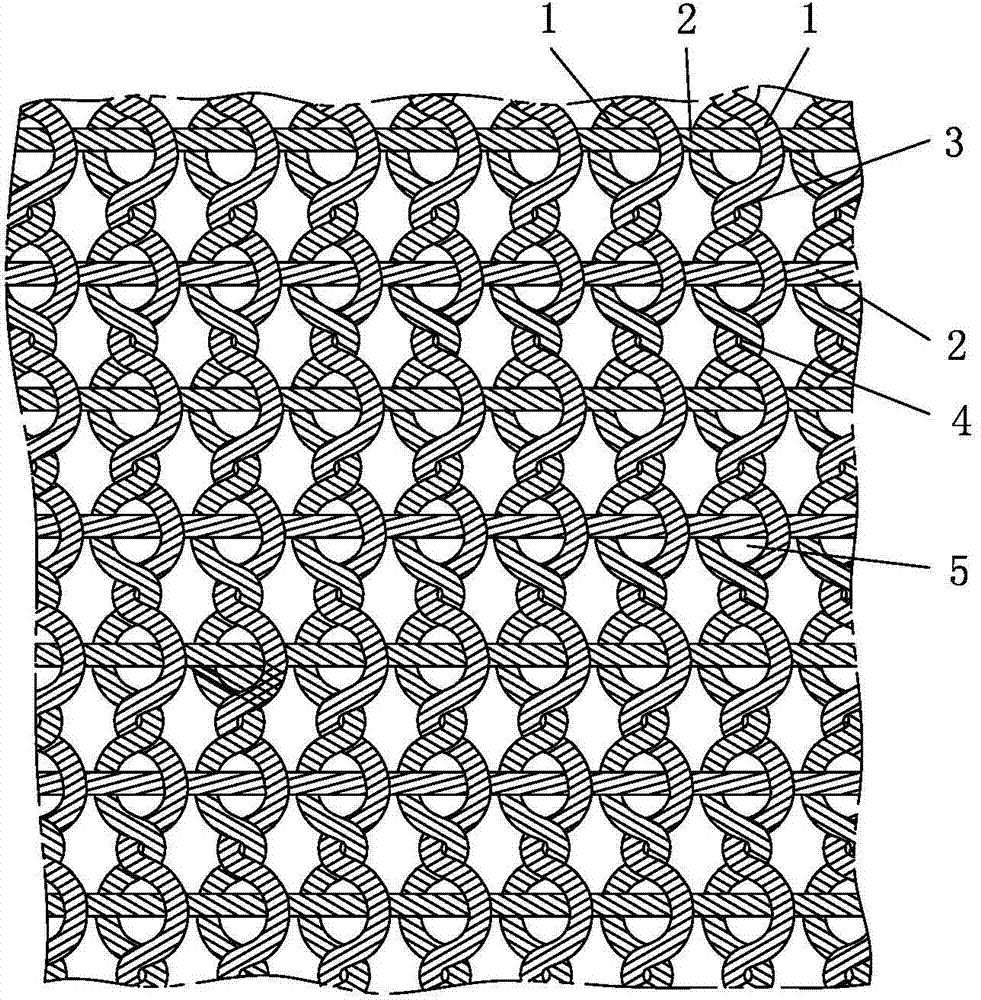

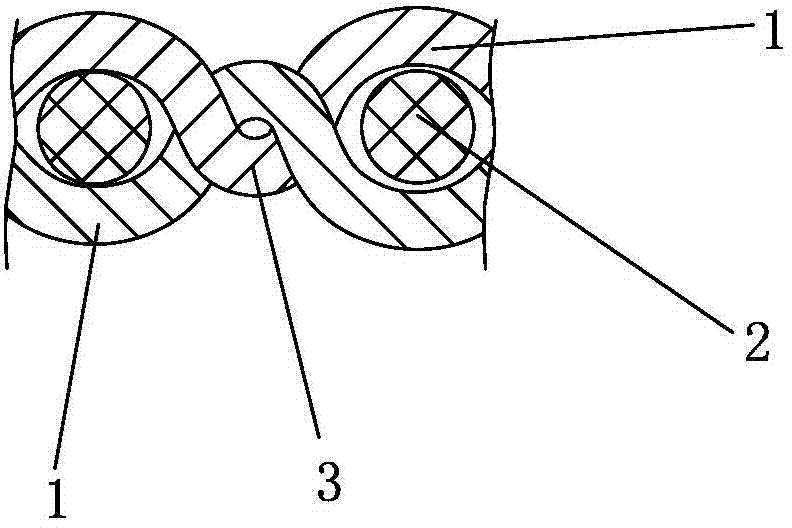

[0016] The present invention will be further described below with specific embodiment, see figure 1 —3:

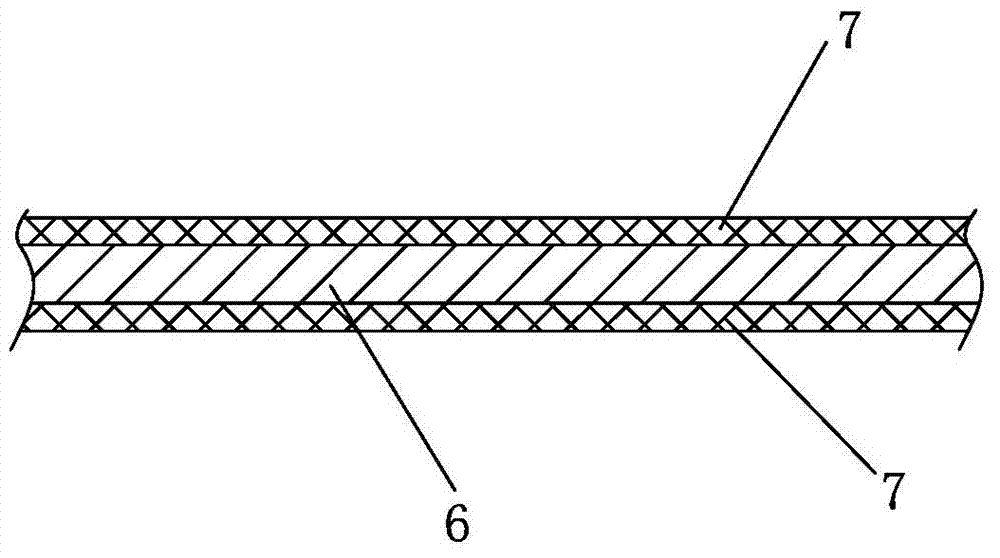

[0017] The warp and weft thread positive and negative twist conveyor belt is interwoven with dipped core cloth, and the white fabric 6 is interwoven and woven by warp 1 and weft 2. The warp 1 is a positive twist yarn formed by twisting more than two strands of raw material silk and The anti-twisted yarn formed by twisting two or more raw material yarns, the weft 2 is a normal twisted yarn formed by twisting two or more raw material yarns and an anti-twisted yarn formed by twisting two or more raw material yarns , the warp 1 and the weft 2 are arranged according to the interval of positive twist and reverse twist or are arranged according to the interval of reverse twist and normal twist. Twist 360°, anti-twist 360° to form positive kink points 3 and anti-kink points 4 arranged at intervals, and the wefts 2 are closely arranged on the positive kink points 3, anti-kink poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com