Double-side adhesion hard screen protection film, production method thereof and use method thereof

A technology of protective film and hard screen, which is applied in the field of hard screen protective film pasted on both sides. It can solve the problems of poor light transmission, low strength, and easy damage of PE film, and achieve strong film fastness, high bonding strength, and light transmission. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

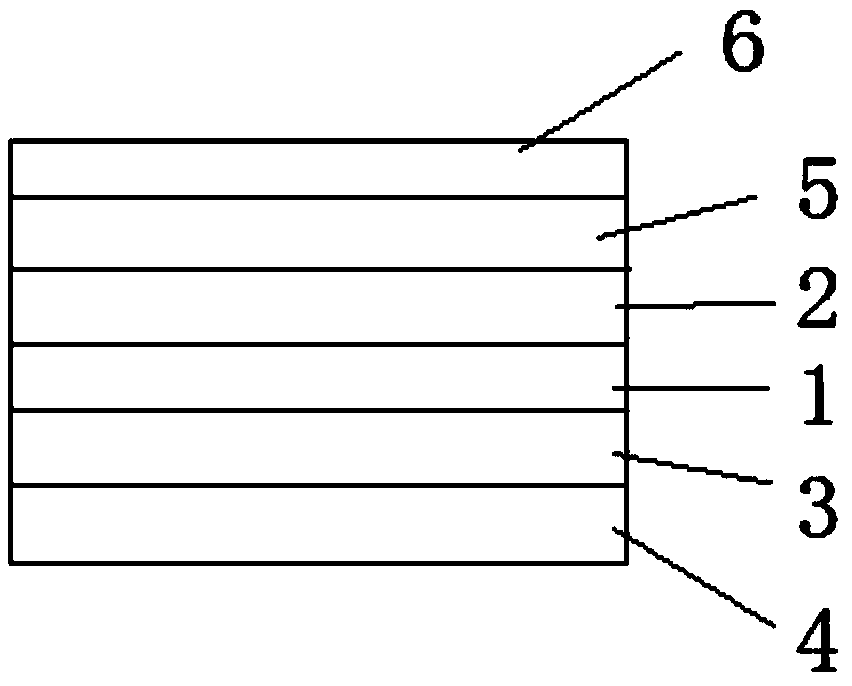

[0014] Such as figure 1 A kind of hard screen protective film pasted on both sides as shown, comprises PET (polyethylene terephthalate) substrate layer 1, and PET substrate layer 1 side surface is provided with organic silicon primer layer 2, can make organic The silicone layer can be combined more firmly with the PET substrate. The surface of the other side of the PET substrate 1 is provided with an acrylate adhesive layer 3, the surface of the acrylate adhesive layer 3 is provided with a release film layer 4, and the surface of the silicone primer layer 2 is coated with a silicone surface adhesive layer 5. Another layer of release film 6 is pasted on the surface of the adhesive layer 5 .

[0015] A production method for sticking a hard screen protective film on both sides, the method comprises the following steps:

[0016] a) On one side of the PET base material, first coat the silicone primer, then coat the silicone surface glue and then apply the release film;

[0017] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com