Aluminum alloy plate with woodgrained paper

A technology of aluminum alloy plate and wood grain paper, which is applied in the field of aluminum alloy plate, can solve the problems of single color and small application range of aluminum alloy plate, and achieve the effect of increasing surface tension, eliminating pollution and ensuring completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

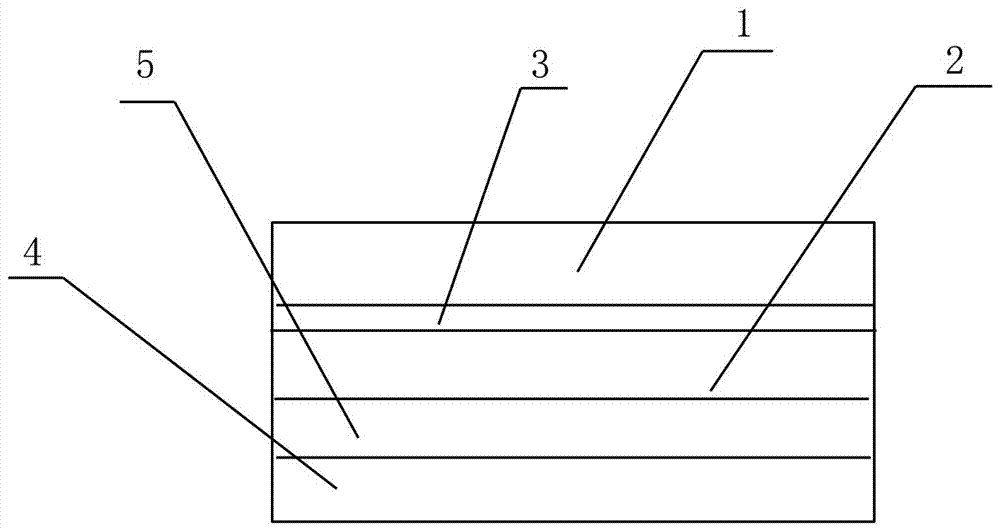

[0008] exist figure 1 Among them, the present invention provides an aluminum alloy plate with wood grain paper, which includes a surface layer 1 and a bottom layer 2, the surface layer 1 is a wood grain paper layer, and the bottom layer 2 is a non-woven fabric layer, and the surface layer 1 and the bottom layer 2 is provided with an adhesive layer 3, the surface layer 1 and the bottom layer 2 are connected through the adhesive layer 3 to form a composite paper layer, the composite paper layer is connected to the decorative aluminum plate 4, and a reinforcing layer is provided between the composite paper layer and the decorative aluminum plate 4 The board surface 5, the reinforced board surface 5 is a gypsum board or a silicate board, and the adhesive layer 3 is a thermoplastic layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com