A kind of all bio-based adhesive and its preparation method and application

An all-biological, glue-based technology, applied in the direction of adhesives, pectin adhesives, adhesive additives, etc., can solve the problems of low cross-linking properties, low board reuse value, poor reactivity, etc., and achieve low harmful gas release, The effect of increasing the value of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

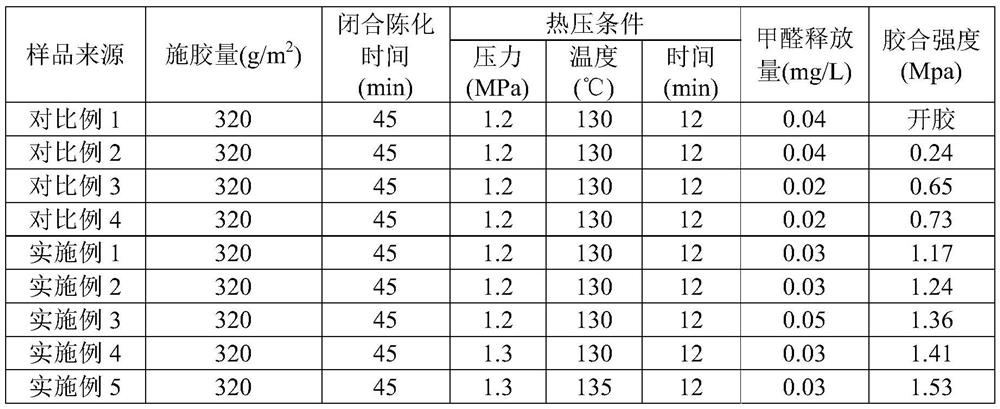

Examples

Embodiment 1

[0039] A preparation method of a full bio-based adhesive, comprising:

[0040] Preparation of demethylated lignin: Demethylation of lignin

[0041] Preparation of demethylated nano-lignin: nano-processing demethylated lignin to obtain demethylated nano-lignin;

[0042] Preparation of oxidized nanocellulose: oxidize nanocellulose to obtain oxidized nanocellulose rich in aldehyde groups;

[0043] Preparation of full bio-based adhesive: demethylated nano-lignin suspension, oxidized nano-cellulose suspension and pectin (purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., the mass content of galacturonic acid is 74%) to obtain by pre-crosslinking polymerization.

[0044] The specific pre-crosslinking polymerization reaction adopts 30% demethylated nano-lignin suspension, 50% oxidized nano-cellulose suspension and pectin, and mixes them according to the mass ratio of 0.5:1:0.05. , at a temperature of 60° C., the reaction was stirred at a speed of 100 rpm for 4 h.

[...

Embodiment 2

[0059] A preparation method of all bio-based adhesives, the difference from Example 1 is:

[0060] The specific pre-crosslinking polymerization reaction is carried out with a mass fraction of 30% demethylated nano-lignin suspension, a mass fraction of 60% oxidized nano-cellulose suspension and pectin, and the mass ratio is 0.5:1:0.1 in sequence. reaction.

[0061] Rotary evaporation in step S32 makes the solid content of the oxidized nanocellulose in the suspension liquid 60%; the others are the same as in Example 1.

Embodiment 3

[0063] A kind of preparation method of all bio-based adhesive, compared with embodiment 1, difference is:

[0064] The specific pre-crosslinking polymerization reaction is carried out with a mass fraction of 40% demethylated nano-lignin suspension, a mass fraction of 50% oxidized nano-cellulose suspension and pectin, according to the mass ratio of 0.5:1:0.1. reaction.

[0065] In step S24, vacuum rotary evaporation is performed on the suspension to make the solid content of the demethylated nano-lignin particles in the suspension to be 40%, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com