Use of bonding resin

A technology of adhesive resin and application, applied in the direction of starch adhesive, protein adhesive, polysaccharide adhesive, etc., can solve the problems of long pressing time and high pressing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, a tannin solution was prepared by adding 70 g of powdered tannin (91% solids content) and 107 g of water to a 500 ml beaker at ambient temperature and stirring until the tannin was completely and uniformly dispersed. Then, 24 g of a 50% sodium hydroxide solution were added to the tannin dispersion. The composition was stirred for 120 minutes to ensure complete dissolution of the tannins in the alkaline medium.

Embodiment 2

[0030] An adhesive formulation was prepared by mixing 23.5 g of the tannin alkaline solution from Example 1 and 7.5 g of the polyglycerol polyglycidyl ether in a beaker for 20 minutes at room temperature using an overhead stirrer.

[0031] The adhesive formulations were tested in lap-joint tests using an Automated Bonding Evaluation System (ABES) tensile tester.

[0032] For this purpose a relatively thin beech veneer with a thickness of 0.6mm cut into 105x20mm pieces was used. The resin was applied to an area of 5mm x 20mm on one side of one end of the two blocks. The overlapping ends of the resin-coated series of test specimens were placed in a hot press at 5 kg / m 2 The pressure was pressed together, using a pressing time of 90 seconds at a pressing temperature of 150 °C. Average data from 5 test specimens are shown in Table 1.

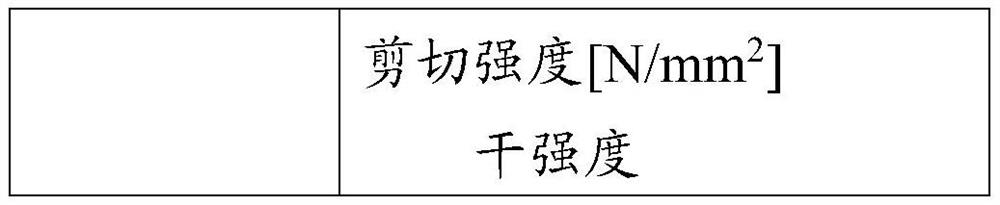

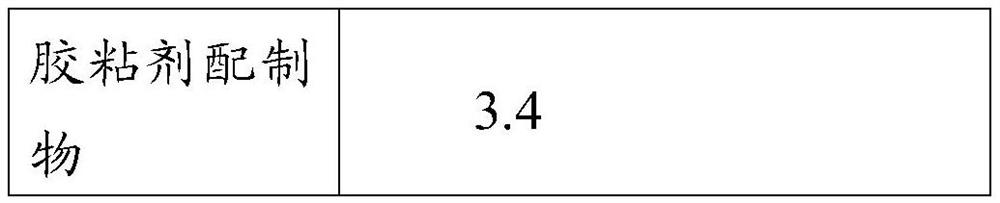

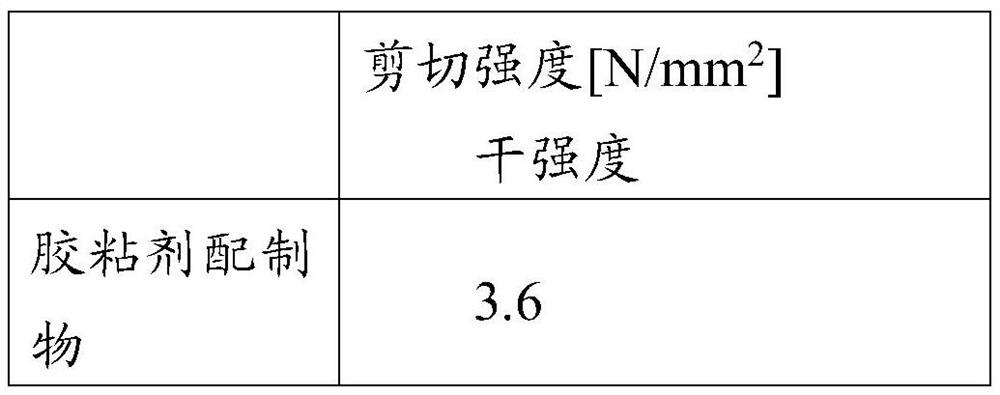

[0033]

[0034]

[0035] Table 1: Shear Strength Using ABES

Embodiment 3

[0037] First, a starch solution was prepared by adding 27 g of powdered starch (90% solid content) and 49 g of water to a 500 ml beaker at a temperature of 80° C. and stirring for 60 minutes. Then, the temperature of the starch dispersion was lowered to 40° C. and 4.9 g of 50% sodium hydroxide solution were added to the starch dispersion. The composition was stirred for 120 minutes to ensure complete dissolution of the starch in the alkaline medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com