Preparation method of corn starch adhesive through cannabis degummed waste liquor

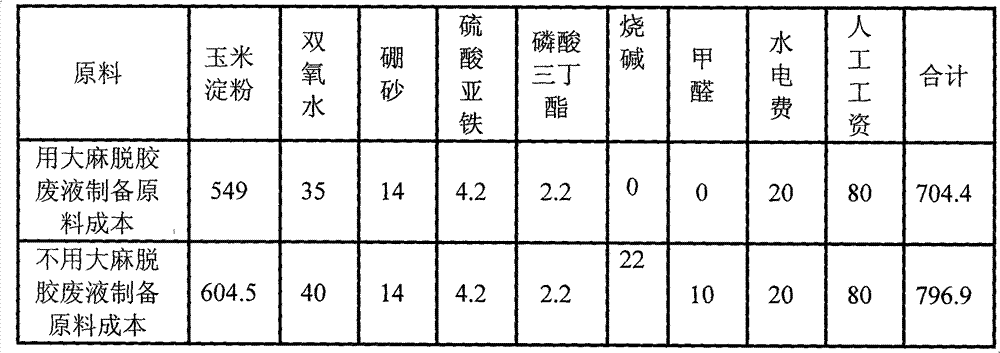

A technology of corn starch glue and corn starch, applied in the direction of starch-derived adhesives, pectin adhesives, adhesive additives, etc., can solve the problems of cannabis degumming waste liquid pollution, etc., to save preparation costs, solve environmental pollution problems, Effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Taking hemp degumming waste liquid containing 4.5% NaOH; 6.5% pectin; 3.1% lignin; 3.2% hemicellulose; 1.7% other solid components; 81% water as an example to prepare corn starch. Specific steps are as follows:

[0018] Step 1: Preparation of Carrier Starch

[0019] Weigh 37.04Kg of cornstarch into the reaction kettle, stir evenly with 95Kg of water, and adjust the temperature of the water bath to 40±2°C. Accurately Weigh Catalyst FeSO 4 Add 0.22Kg to 5Kg of water to dissolve and add to the reaction kettle. Weigh the cannabis degumming waste liquid 265.00Kg again, slowly add part of the cannabis degumming waste liquid to the reactor, and constantly measure the pH value of the carrier starch to 11.0-11.2 (add about 55.0Kg of the cannabis degumming waste liquid). Take 8.88Kg 30%H 2 o 2 And dilute with 7.78Kg water, slowly add carrier starch solution. React for 120 minutes, after the starch oxidation is complete, add all the remaining hemp degumming waste liquid, st...

Embodiment 2

[0025] The hemp degumming waste liquid contains 5.0% NaOH; 6.8% pectin; 3.3% lignin; 3.4% hemicellulose; 1.9% other solid components; Take cornstarch as an example. Specific steps are as follows:

[0026] Step 1: Preparation of Carrier Starch

[0027] Weigh 37.04Kg of cornstarch into the reaction kettle, stir evenly with 95Kg of water, and adjust the temperature of the water bath to 40±2°C. Accurately Weigh Catalyst FeSO 4 Add 0.22Kg to 5Kg of water to dissolve and add to the reaction kettle. Weigh the cannabis degumming waste liquid 263.00Kg again, slowly add part of the cannabis degumming waste liquid to the reactor, and constantly measure the pH value of the carrier starch to 11.0-11.2 (add about 54.0Kg of the cannabis degumming waste liquid). Take 8.88Kg 30%H 2 o 2 And dilute with 7.78Kg water, slowly add carrier starch liquid. React for 120 minutes, after the starch oxidation is complete, add all the remaining hemp degumming waste liquid, stir evenly and set aside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com