Louvre blade and hollow glass louvre

A technology of louver blades and shutters, which is applied in the field of shutters, can solve the problems of limitation, difficulty in shading coefficient and thermal insulation performance of hollow louver glass, and achieve good energy-saving performance, high shading coefficient, and high thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation will be described below in conjunction with the accompanying drawings.

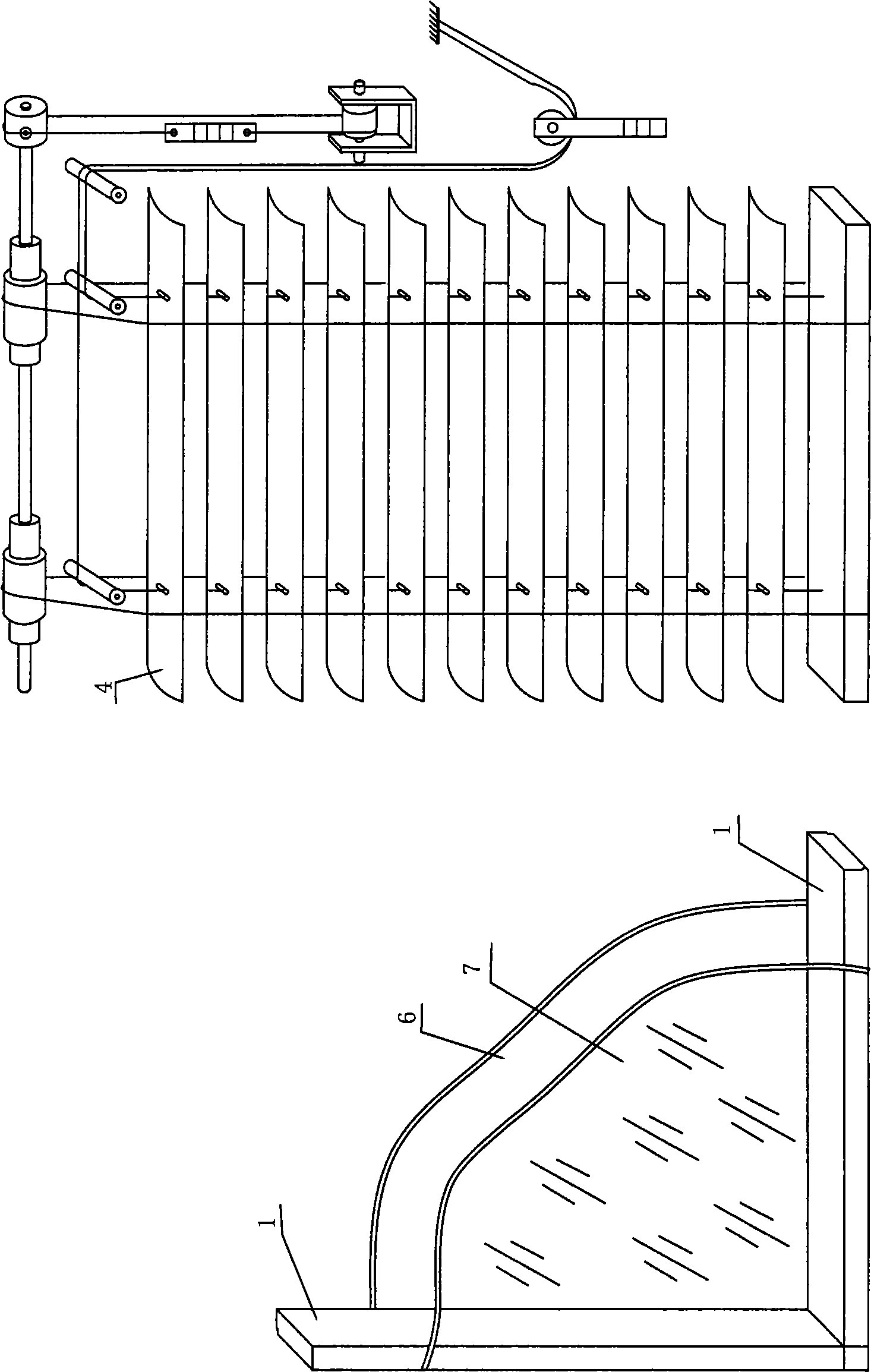

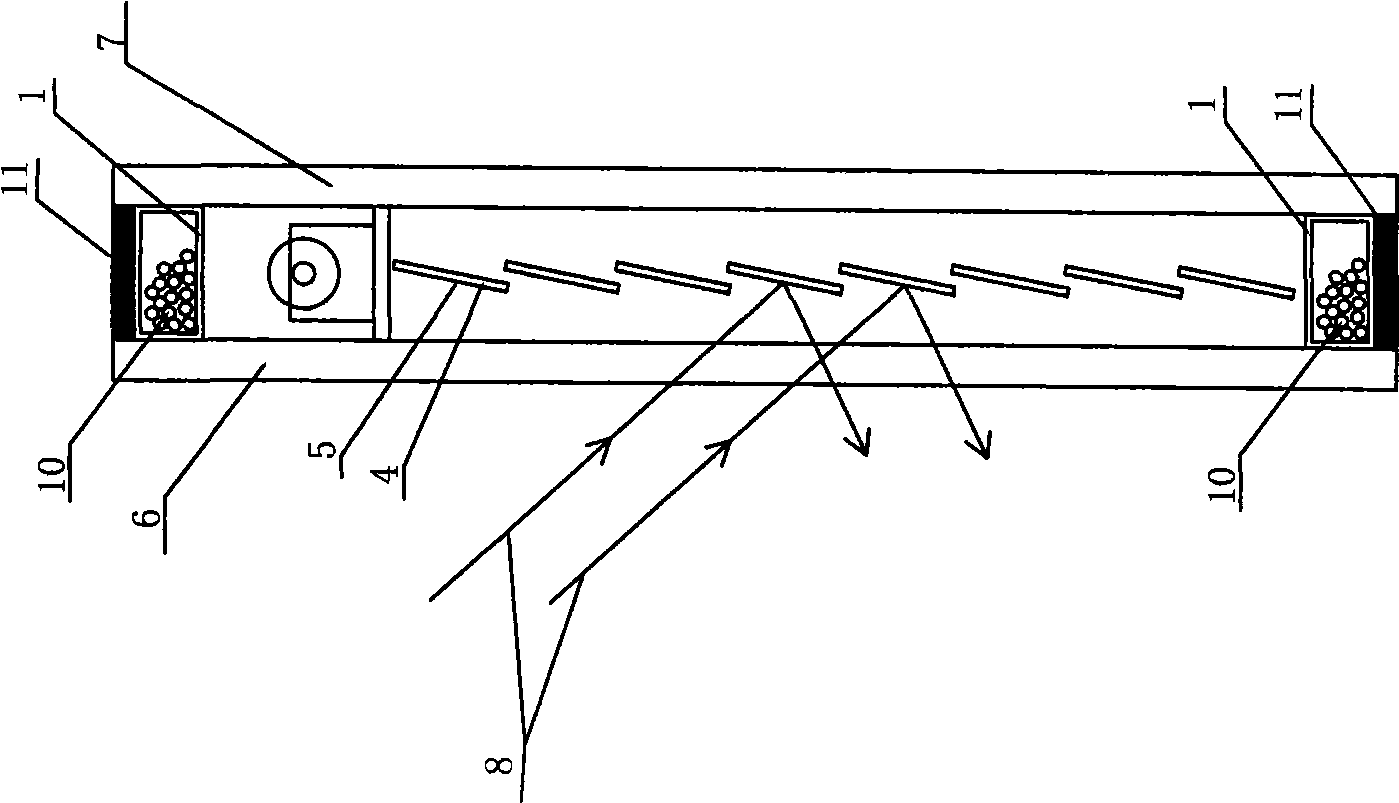

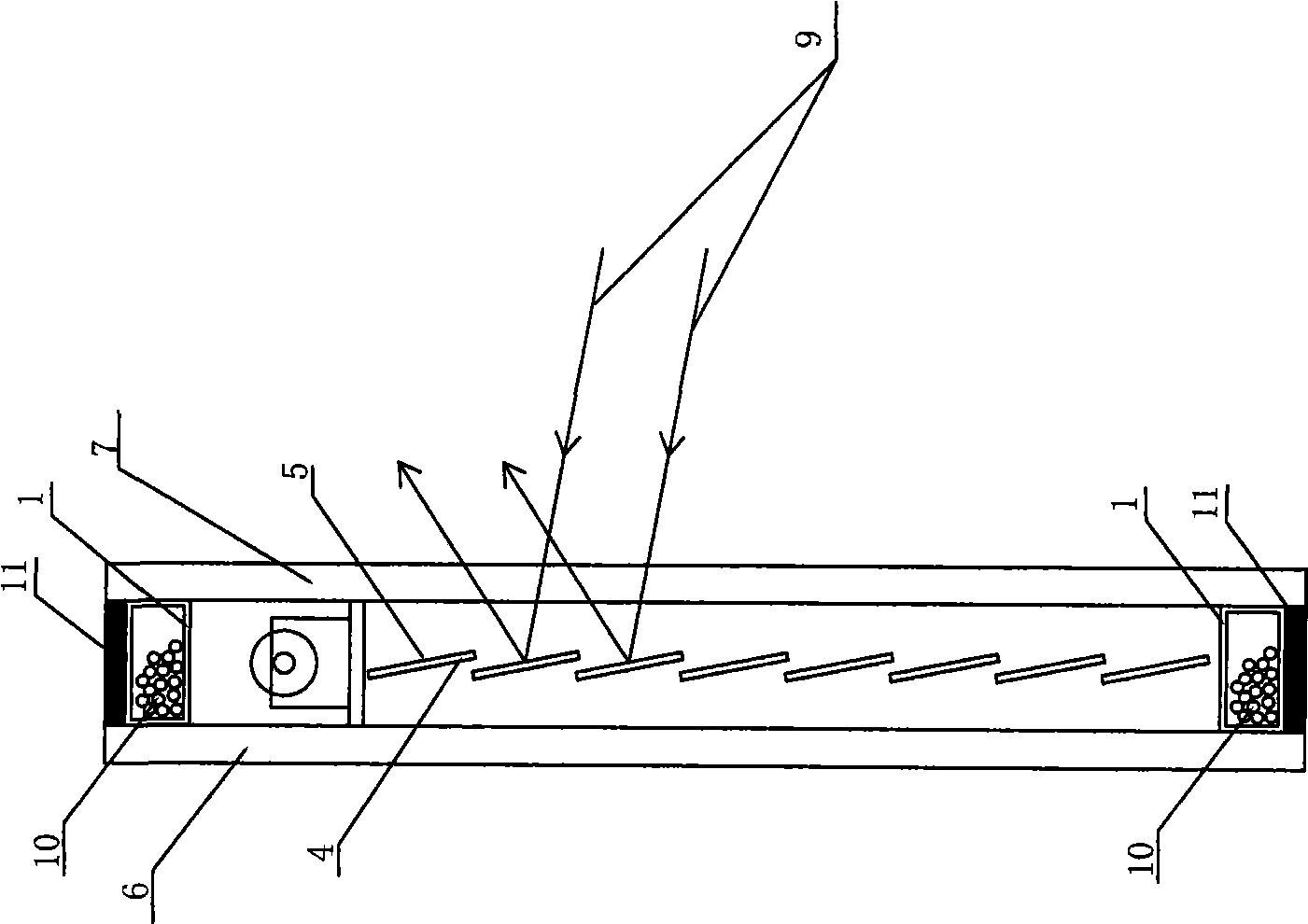

[0041] See Figure 2A ,and Figure 2B , are the hollow glass louvers with a heat reflective layer on the single surface of the louvers, the schematic diagrams of the heat reflective layer facing outdoors and indoors when the venetian blind is put down and closed, the hollow louver glass is composed of a support frame 1, Desiccant 10 inside, outdoor side glass 6, indoor side glass 7, sealant 11 and several louver blades 4 with heat reflection layer 5, etc. Show.

[0042] In this embodiment, the louver 4 has a heat reflective layer 5 on one side. When the outdoor temperature is high and sunshade is required, make the hollow louver glass Figure 2A state, that is, open the louvers to form a larger reflective surface, and make the heat reflective layer 5 of the louver 4 face the sunlight 8, because the surface of the louver 4 has a heat reflective layer 5, so more sunlig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com