Single silver LOW-E glass coating film production line

A coating production line and glass technology, applied in the field of single-silver LOW-E glass coating production line, can solve the problems of inability to coat LOW-E glass, low production efficiency and high equipment cost, avoid the formation of sputtered oxide layers, The effect of short pumping time and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail and completely below in conjunction with Examples and Comparative Examples.

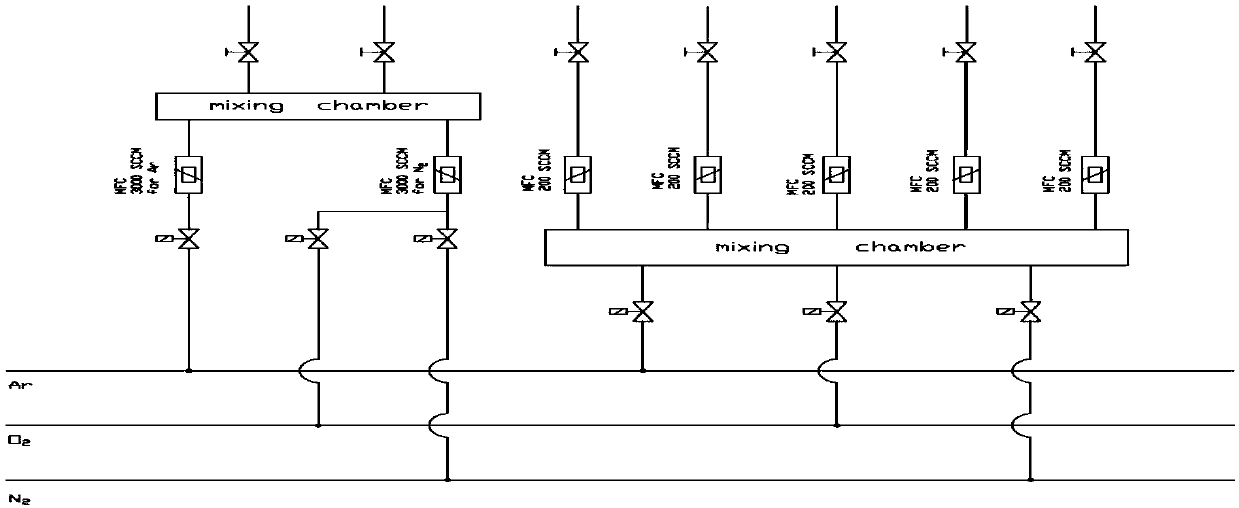

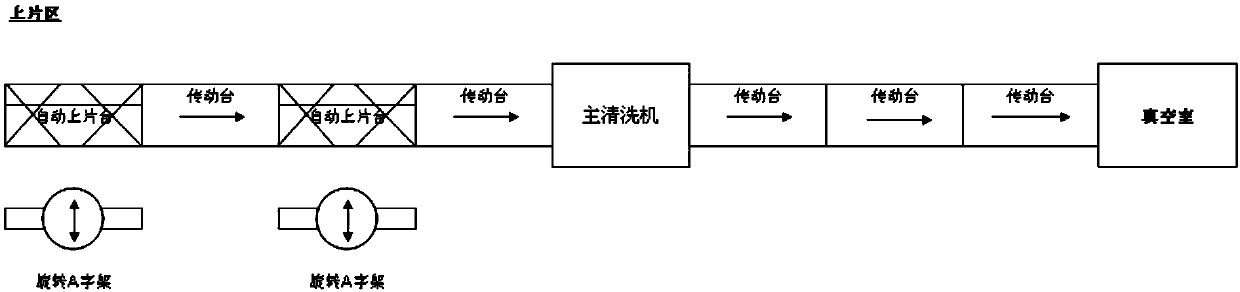

[0053] The single-silver LOW-E glass coating production line of the present invention is used to make single-silver temperable LOW-E on flat architectural glass, and is suitable for preparing glass with a size of 2,540mmx47000mm. The fastest mechanical cycle time is 45 seconds, and the actual cycle time depends on Depending on the cathode arrangement and the type of film produced, the glass sheets are conveyed by a horizontal conveyor system.

[0054] Platable glass specifications and capacity:

[0055] Maximum size: 9400×2540;

[0056] Normal specification: 4700×2540;

[0057] Minimum size: 300×1100;

[0058] Thickness range: 5mm-6mm;

[0059] Capacity: 4.6 million m 2 / year.

[0060] The length of the vacuum chamber is about 89 meters, the total length of the production line including peripheral equipment is about 175 meters, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com