High-transparency low-radiation coated glass and preparation method thereof

A low-emissivity coating and high-transmittance technology, applied in the field of glass, can solve problems such as poor acid resistance, and achieve the effects of good film firmness, high light transmittance, and good alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

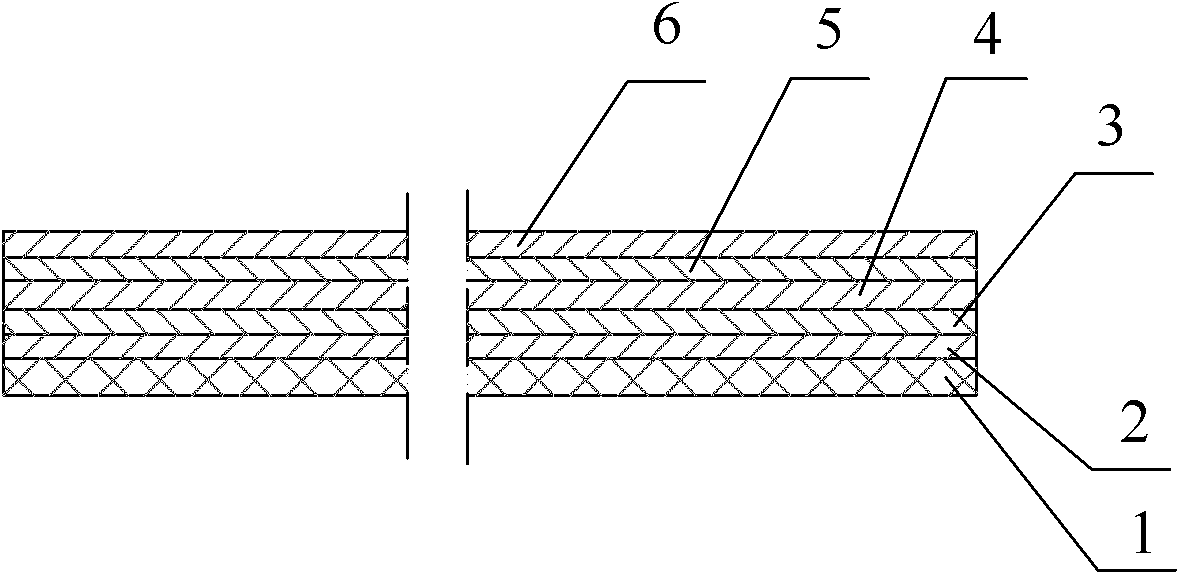

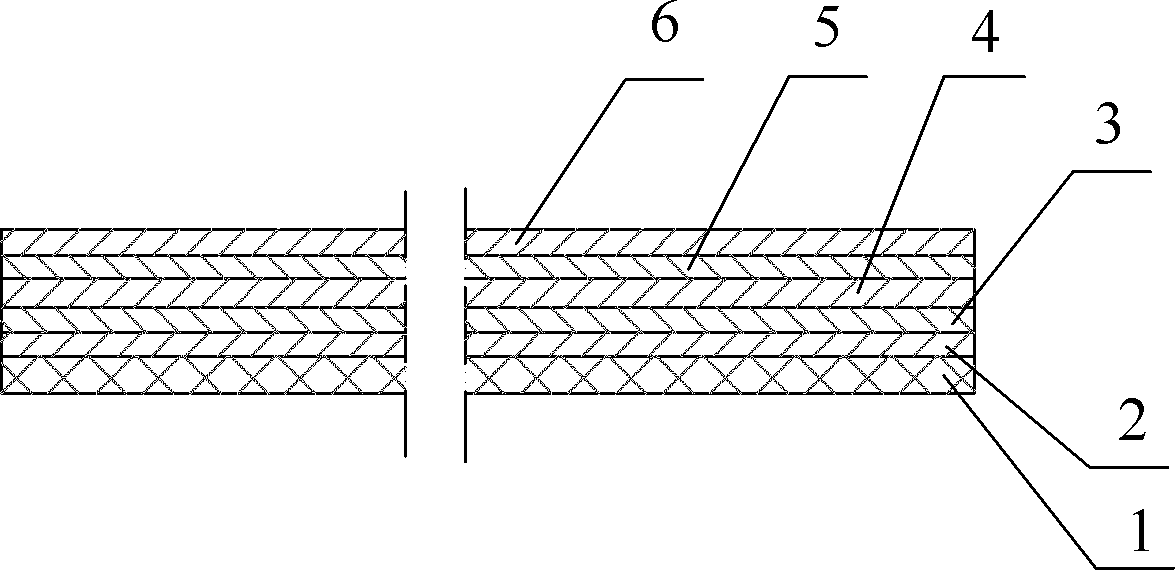

[0031] Embodiment 1, figure 1 and figure 2 Combined with a high-transmittance low-emissivity coated glass, a dielectric layer I2, a nickel-chromium alloy layer I3, a silver layer 4, a nickel-chromium alloy layer II5 and a dielectric layer II6 are sequentially arranged on the surface of a glass substrate 1 from bottom to top; The dielectric layer I2 is connected to the surface of the glass substrate 1; both the dielectric layer I2 and the dielectric layer II6 are zinc oxide stannate layers. The thickness of glass substrate 1 is 6mm, and the thicknesses of dielectric layer I2, nickel-chromium alloy layer I3, silver layer 4, nickel-chromium alloy layer II5 and dielectric layer II6 are 44nm, 0.8nm, 9nm, 0.8nm and 32nm in sequence.

[0032] Its preparation method is to carry out following steps successively:

[0033] 1. Preparation of coating materials:

[0034] The dielectric layer I2 and the dielectric layer II6 use a cast cylindrical target mixed with tin and zinc as the tar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com