High-performance double-silver low-radiation energy-saving glass

A low-emission coating, glass technology, applied in glass/slag layered products, applications, chemical instruments and methods, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

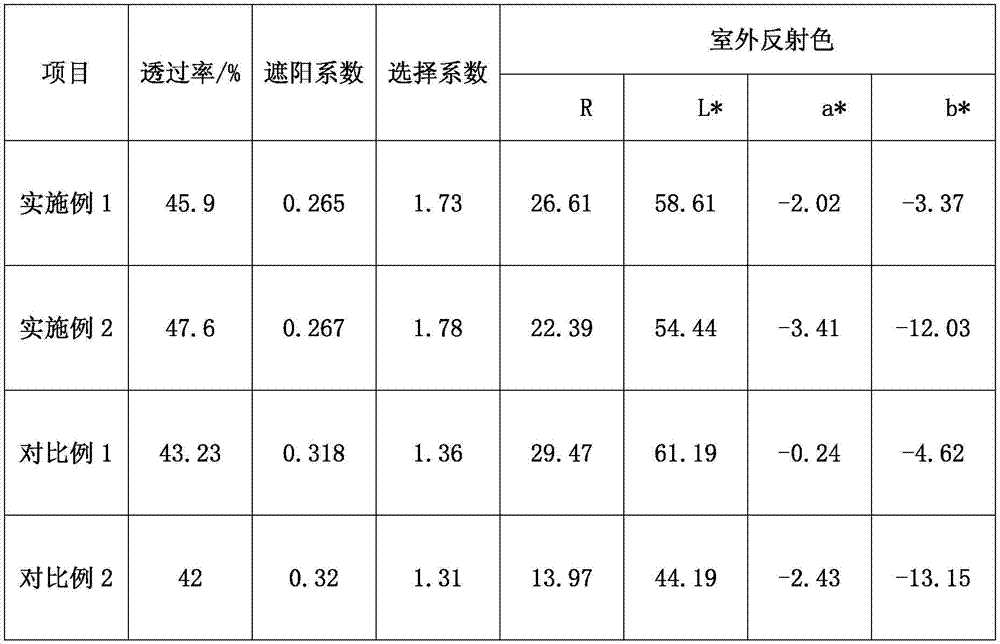

Embodiment 1

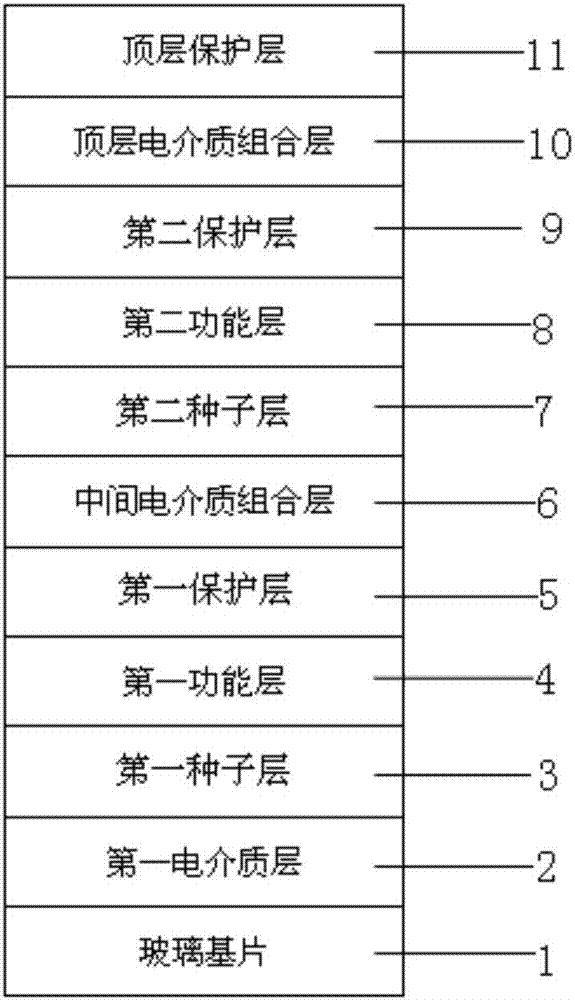

[0024] Using vacuum off-line magnetron sputtering coating equipment, 7nm silicon nitride layer, 9nm zinc oxide layer, 17nm silver layer, 3nm nickel-chromium layer, 29nm silicon nitride layer are sequentially plated on a 6mm high-quality float glass substrate from inside to outside layer, 40nm zinc tin oxide layer, 10nm zinc oxide layer, 12nm silver layer, 3nm nickel chrome layer, 5nm ceramic zinc oxide layer, 28nm silicon nitride layer and 5nm graphite layer.

Embodiment 2

[0026] Using vacuum off-line magnetron sputtering coating equipment, on a 6mm high-quality float glass substrate, 12nm silicon nitride layer, 10nm zinc oxide layer, 17nm silver layer, 3nm nickel-chromium nitride layer, 29nm nitrogen Silicon oxide layer, 39nm zinc tin oxide layer, 10nm zinc oxide layer, 7nm silver layer, 3nm nickel-chromium layer, 5nm ceramic zinc oxide layer, 29nm silicon nitride layer and 5nm graphite layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com