Nano-composite optothermal response system, resin material and smart glass

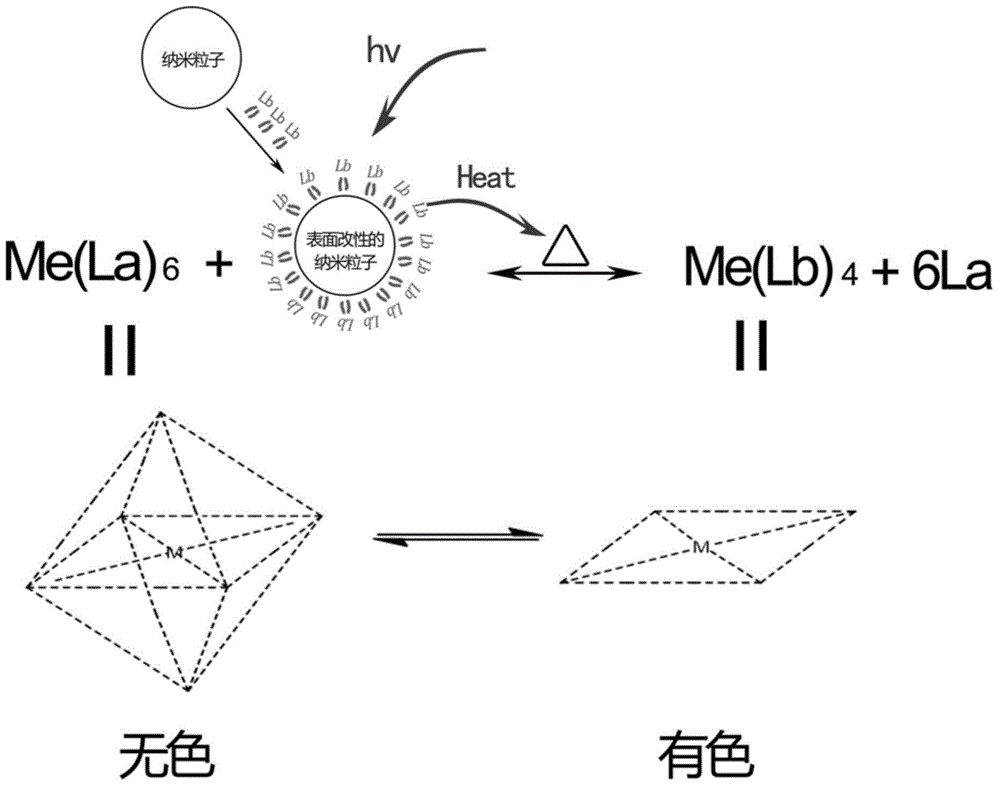

A photothermal response, nano-composite technology, applied in synthetic resin layered products, glass/slag layered products, applications, etc., can solve the problems of affecting the line of sight, poor permeability, etc., to facilitate film-forming processing, promote photothermal The effect of conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

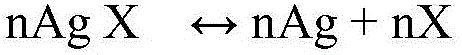

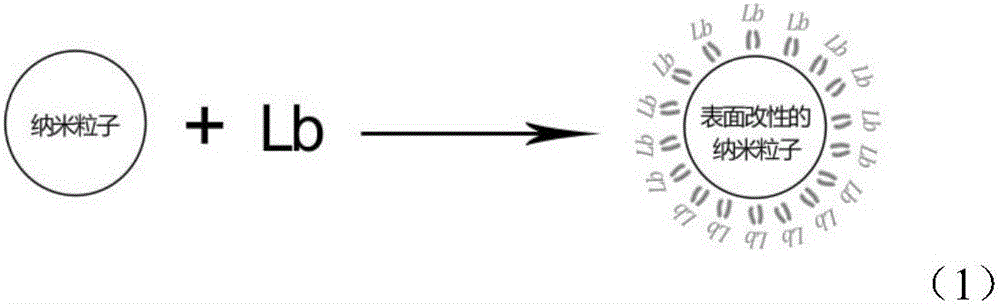

Method used

Image

Examples

Embodiment 1

[0076] 1 kg of zinc oxide particles with a particle size of 5 nanometers, 3 kg of pentaerythritol, and 15 kg of dioxane were ground for two hours with a sand mill of zirconia particles with a particle size of 0.3 mm to obtain surface polyol-modified nano Zinc oxide solution.

Embodiment 2

[0078] 50 grams of tungsten oxide particles with a particle diameter of 20 nanometers were dispersed in 2 liters of absolute ethanol solution, and 5 milliliters of hydroxypropyltriethoxysilane was added. React under vigorous stirring for 24 hours, then centrifuge to remove ethanol. The dried surface-modified nano-tungsten oxide was dispersed into 2L dimethyl glutarate solution through a sand mill. The hydroxyl content was 2 mol / kg.

Embodiment 3

[0080] 100 grams of alum pentoxide nanoparticles with a particle diameter of 500 nanometers were dispersed in 2 liters of absolute ethanol solution. Slowly add 20 ml of chlorobenzyltriethoxysilane under stirring condition. The reaction was carried out under vigorous stirring for 24 hours. The reaction solution was passed through nitrogen to remove oxygen for 20 minutes, and then 20 grams of cuprous chloride, 10 grams of bipyridine and 200 grams of hydroxyethyl acrylate were added. The temperature of the reaction solution was raised to 70°C, and the reaction was carried out for 2 hours. Centrifuge and dry to prepare 1905 g of surface-grafted vanadium pentoxide nanoparticles with a hydroxyl content of 5 mol / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com