High-strength aluminum alloy profile and manufacturing technique thereof

An aluminum alloy profile and manufacturing process technology, applied in the field of aluminum alloy materials, can solve the problems of complex manufacturing process, low product strength, easy deformation, etc., and achieve the effects of simple manufacturing process, improved strength, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

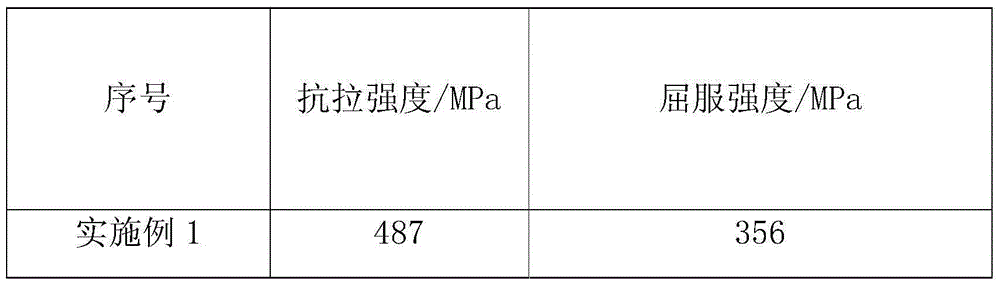

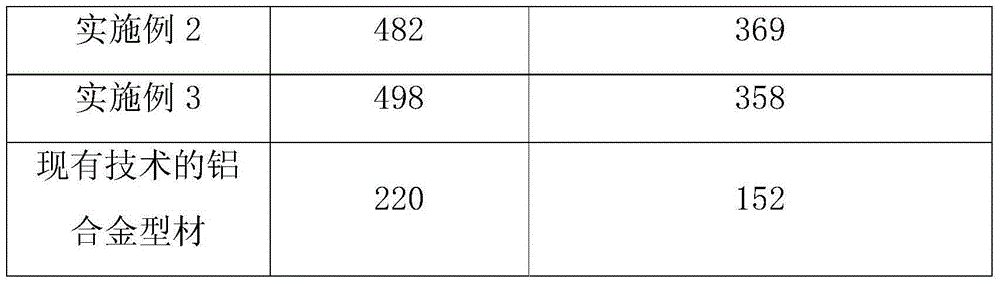

Examples

Embodiment 1

[0016] A high-strength aluminum alloy profile consisting of the following substances by mass percentage: 3% magnesium, 1% silicon, 2.4% iron, 0.8% copper, 1.3% manganese, 0.1% strontium, 0.5% zirconium, 0.5% titanium, 2% nichrome and the rest aluminum.

[0017] A manufacturing process of a high-strength aluminum alloy profile, comprising the following steps:

[0018] 1) Material preparation: calculate and weigh the charge according to the formula ratio;

[0019] 2) Melting: Put the charge in step (1) into the smelting furnace. When the temperature of the melt reaches 740°C, sprinkle a layer of covering agent on the surface of the melt. When the charge is completely melted, remove the scum on the surface. Adjust the temperature to 710°C, use an electromagnetic stirrer to stir the melt for 15 minutes to make the temperature in the molten pool uniform, then add 1.3% refining agent to the weight of the melt to refine the aluminum alloy melt for 10 minutes, and then remove the sur...

Embodiment 2

[0022] A high-strength aluminum alloy profile consisting of the following substances by mass percentage: 5% magnesium, 4% silicon, 3% iron, 1% copper, 1.8% manganese, 0.5% strontium, 0.8% zirconium, 0.8% titanium, 9% nichrome, and the rest is aluminum.

[0023] A manufacturing process of a high-strength aluminum alloy profile, comprising the following steps:

[0024] 1) Material preparation: calculate and weigh the charge according to the formula ratio;

[0025] 2) Melting: Add the charge in step (1) into the melting furnace. When the temperature of the melt reaches 760°C, sprinkle a layer of covering agent on the surface of the melt. When the charge is completely melted, remove the scum on the surface. Adjust the temperature to 720°C, use an electromagnetic stirrer to stir the melt for 25 minutes to make the temperature uniform throughout the molten pool, then add a refining agent equal to 2% of the melt weight to refine the aluminum alloy melt for 15 minutes, and then remov...

Embodiment 3

[0028] A high-strength aluminum alloy profile consisting of the following substances by mass percentage: 3% magnesium, 1.5% silicon, 3% iron, 1% copper, 1.5% manganese, 0.2% strontium, 0.5% zirconium, 0.5% titanium, 6% nichrome and the rest aluminum.

[0029] A manufacturing process of a high-strength aluminum alloy profile, comprising the following steps:

[0030] 1) Material preparation: calculate and weigh the charge according to the formula ratio;

[0031] 2) Melting: Add the charge in step (1) into the melting furnace. When the temperature of the melt reaches 750°C, sprinkle a layer of covering agent on the surface of the melt. When the charge is completely melted, remove the scum on the surface. Adjust the temperature to 715°C, use an electromagnetic stirrer to stir the melt for 20 minutes to make the temperature in the molten pool uniform, then add a refining agent equal to 2% of the melt weight to refine the aluminum alloy melt for 12 minutes, and then remove the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com