Method of metalizing reverse side of single pipe core

A technology of backside and metallization of die, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of difficult implementation of die, and achieve the effect of saving time, good use effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Metallize the back of the die with a specification (length×width×thickness) of 4.65mm×3.95mm×0.45mm. The specific steps are as follows:

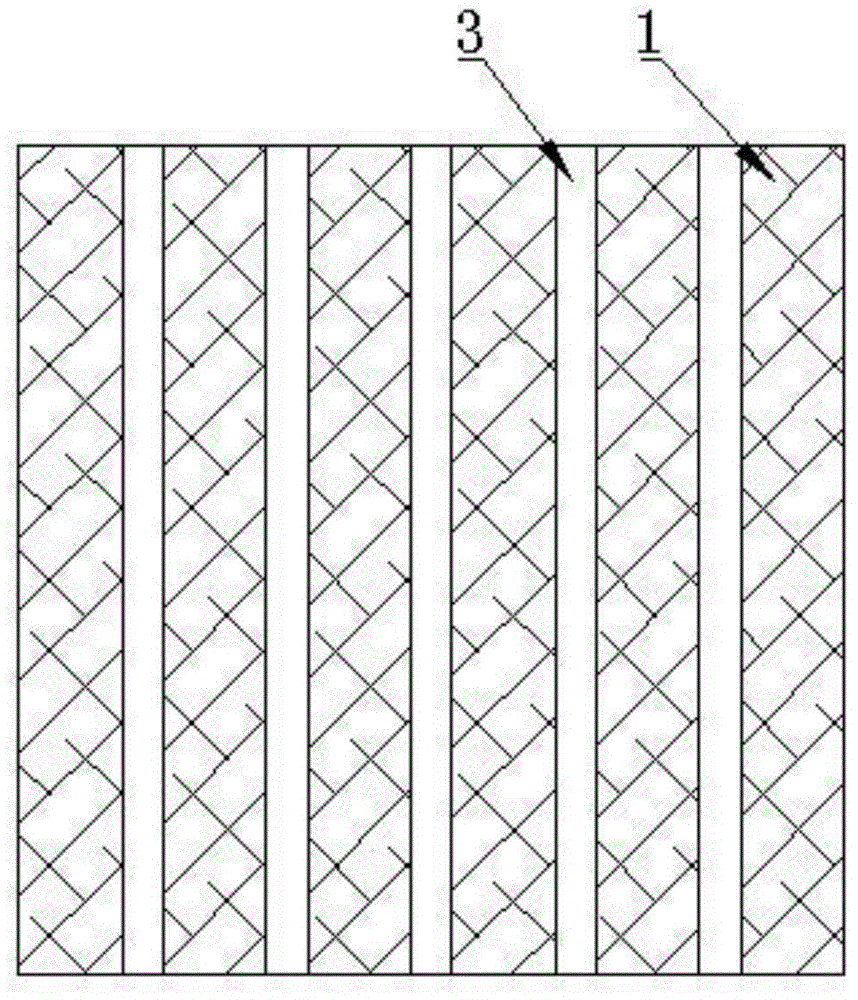

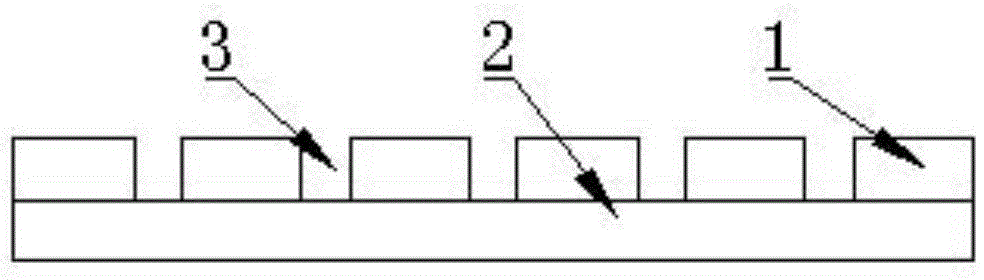

[0025] (1), the glass-ceramics substrate that the thickness is 0.5mm is divided into the glass-ceramics spacer bar that width is 6mm, get 6 glass-ceramic spacer bars and be bonded on the film crystallite that the thickness of substrate is 0.5mm On the glass substrate, the two adjacent glass-ceramic spacers form a die placement groove with a width of 3.97 mm, and are made into a die placement mold with five die placement grooves, as shown in the figure;

[0026] (2), take 5 individual tube cores and place them respectively in the tube core placement grooves of the tube core placement mold with the back facing up, and send them into the sputtering chamber of the magnetron sputtering table, and the purity of the feed is 99.99% % argon as the reaction gas, the gas flow rate is 12sccm, and the vacuum degree of the control sputtering chambe...

Embodiment 2

[0032] Metallize the back of the die with a specification (length×width×thickness) of 4mm×3.15mm×0.42mm. The specific steps are as follows:

[0033] (1), making die placement mold

[0034] A glass-ceramic substrate with a thickness of 0.5 mm is divided into glass-ceramic spacers with a width of 5.5 mm, and 6 glass-ceramic spacers are bonded on the thin-film glass-ceramic substrate as the substrate. Two glass-ceramic spacers form a die placement groove with a width of 3.175mm, and make a die placement mold with five die placement grooves, as shown in the figure;

[0035] (2), take 5 individual tube cores and place them respectively in the tube core placement grooves of the tube core placement mold with the back facing up, and send them into the sputtering chamber of the magnetron sputtering table, and the purity of the feed is 99.99% % argon as the reaction gas, the gas flow rate is 13sccm, and the vacuum degree of the control sputtering chamber is 5.5×10 -5 Pa;

[0036] (3)...

Embodiment 3

[0041] Metallize the back of the die with a specification (length×width×thickness) of 2.5mm×1.5mm×0.44mm. The specific steps are as follows:

[0042] (1), making die placement mold

[0043] A glass-ceramic substrate with a thickness of 0.5 mm is divided into glass-ceramic spacers with a width of 5 mm, and 6 glass-ceramic spacers are bonded on the thin-film glass-ceramic substrate as the substrate. A glass-ceramic spacer forms a die placement groove with a width of 1.53mm, and is made into a die placement mold with five die placement grooves, as shown in the figure;

[0044] (2), take 5 individual tube cores and place them respectively in the tube core placement grooves of the tube core placement mold with the back facing up, and send them into the sputtering chamber of the magnetron sputtering table, and the purity of the feed is 99.99% % argon as the reaction gas, the gas flow rate is 14sccm, and the vacuum degree of the control sputtering chamber is 5×10 -5 Pa;

[0045] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com