Spraying material for heating surface of boiler tube of garbage incinerator and construction process thereof

A waste incinerator and spraying material technology, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of tube wall wear, affect the service life of boiler equipment, reduce the service life of boilers, etc., and reduce wear , improve resistance, and reduce the number of "pipe burst" effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

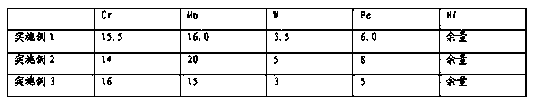

[0014] Embodiments of the present invention include the following:

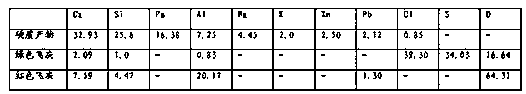

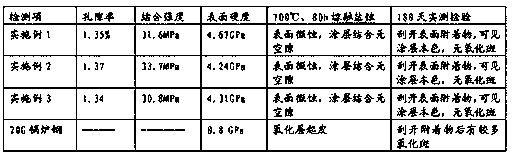

[0015] First of all, analyzing the incineration products of the waste incinerator, it can be found that the main incineration products of the waste incinerator can be divided into two types: hard cement slagging and powder fly ash. The surface of the former is mostly green and extremely hard; the latter Green or red. It can be seen from the elemental analysis table of waste incineration products in Table 1 that the hard bonded products are mainly oxides composed of Ca, Si, Fe and other elements (O element is not in the detection range), thus reflecting extremely hard appearance characteristics ; In addition, a small amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com