Ceramic glue spreader for paper packaging

A technology for ceramic coating and packaging. It is applied in coatings, devices for coating liquid on the surface, machining/deformation, etc. It can solve the problems of texture wear, uneven glue coating, jumping, etc., and reduce carbon emissions. , Reduce energy consumption and shorten drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

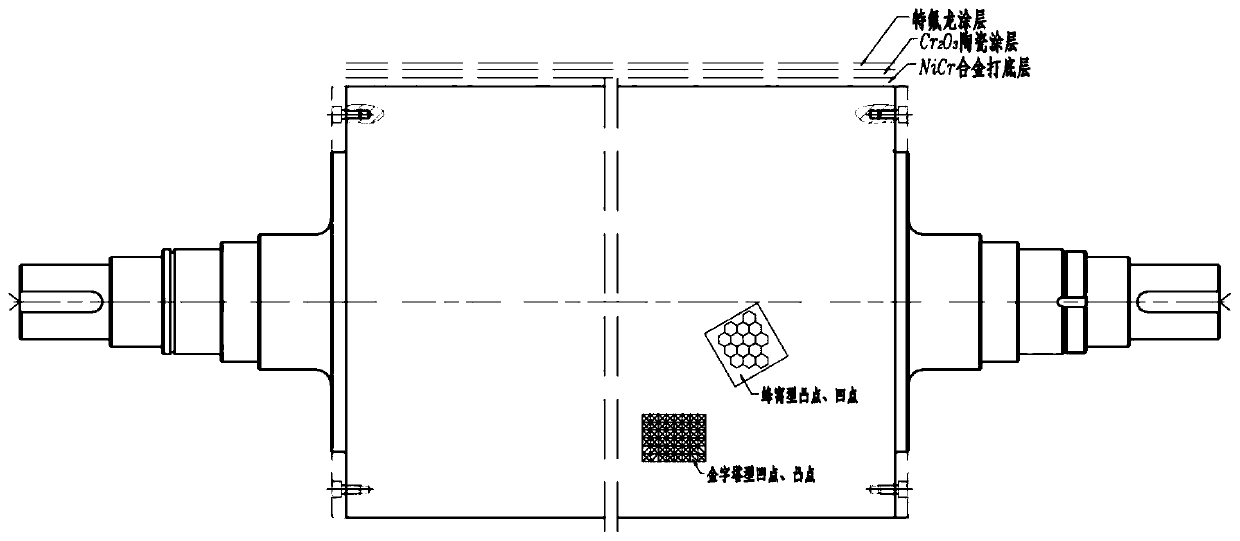

[0017] During the specific implementation of the present invention, a 0.1mm nickel-chromium alloy primer layer is sprayed on the surface of the steel roller to prevent the iron core from being corroded by glue and rust; Ceramic surface, the accuracy can reach within 0.01mm. Laser engraving machine is used to engrave the texture on the surface of the ceramic. The amount of glue required by the customer of the network cable is different. It can engrave 20-60 lines of pyramid-shaped concave-point texture, honeycomb-shaped concave-point texture, pyramid-shaped convex-point texture, and honeycomb shape. Convex dot texture, used for glue transfer.

[0018] The high-precision gluing roller is guaranteed. At the same time, according to the viscosity of the glue, anti-sticking coatings such as Teflon can also be sprayed on the surface of the ceramic gluing roller to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com