High-temperature-corrosion-resistant alloy coating of boiler heating surface and preparation method thereof

A high-temperature corrosion-resistant, alloy coating technology, applied in the direction of metal material coating process, coating, melt spraying, etc., to enhance the density and hardness, improve the density and bonding force, good tissue stability and reliable use sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

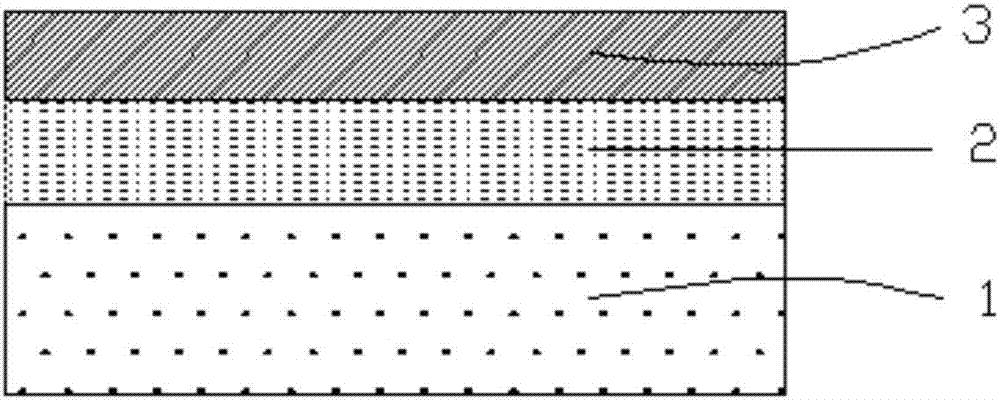

[0038] Such as figure 1 As shown, the high-temperature corrosion-resistant alloy coating on the heating surface of the boiler in this embodiment is a base layer 2 and a surface layer 3 from the base 1 to the outside in turn, the base layer 2 is a NiCrAlY alloy coating, and the surface layer 3 is Incone1625 / NiCr alloy coating; the thickness of the primer layer 2 is 90-110 μm, and the thickness of the surface layer 3 is 350-500 μm.

[0039] The preparation method of the high temperature corrosion resistant alloy coating on the boiler heating surface of the present embodiment comprises the following steps:

[0040] (1) Mix Inconel625 alloy powder and NiCr alloy powder uniformly in proportion to obtain composite alloy powder, and dry it for use.

[0041] Specifically weigh 75% of Inconel625 alloy powder and 25% of NiCr alloy powder by mass percentage, mix uniformly, and make an average particle diameter of 25-55 μm spherical composite alloy powder, dry the moisture in an oven wi...

Embodiment 2

[0057] Such as figure 1 As shown, the high-temperature corrosion-resistant alloy coating on the heating surface of the boiler in this embodiment is a base layer 2 and a surface layer 3 from the base 1 to the outside in turn, the base layer 2 is a NiCrAlY alloy coating, and the surface layer 3 is Incone1625 / NiCr alloy coating; the thickness of the primer layer 2 is 90-110 μm, and the thickness of the surface layer 3 is 350-500 μm.

[0058] The preparation method of the high temperature corrosion resistant alloy coating on the boiler heating surface of the present embodiment comprises the following steps:

[0059] (1) Mix Inconel625 alloy powder and NiCr alloy powder uniformly in proportion to obtain composite alloy powder, and dry it for use.

[0060] Specifically, weigh 60% of Inconel625 alloy powder and 40% of NiCr alloy powder according to mass percentage, mix them evenly, and obtain a spherical composite powder with an average particle size of 25-55 μm, dry the water in a...

Embodiment 3

[0069] Such as figure 1 As shown, the high-temperature corrosion-resistant alloy coating on the heating surface of the boiler in this embodiment is a base layer 2 and a surface layer 3 from the base 1 to the outside in turn, the base layer 2 is a NiCrAlY alloy coating, and the surface layer 3 is Incone1625 / NiCr alloy coating; the thickness of the primer layer 2 is 90-110 μm, and the thickness of the surface layer 3 is 350-500 μm.

[0070] The preparation method of the high temperature corrosion resistant Incone1625 / NiCr-NiCrAlY alloy coating of the boiler heating surface of the present embodiment comprises the following steps:

[0071] (1) Mix Inconel625 alloy powder and NiCr alloy powder uniformly in proportion to obtain composite alloy powder, and dry it for use.

[0072] Specifically, weigh 90% of Inconel625 alloy powder and 10% of NiCr alloy powder by mass percentage, mix uniformly, and obtain an average particle diameter of 25-55 μm spherical composite alloy powder, dry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com