A tin-copper-nickel alloy electroplating solution and an electroplating method thereof

A nickel alloy and electroplating solution technology, applied in the field of electroplating solution, can solve the problems of poor processing performance, poor stability of the plating solution, easy occurrence of whiskers, etc., and achieve the effects of strong processing performance, good thermal stability and good ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

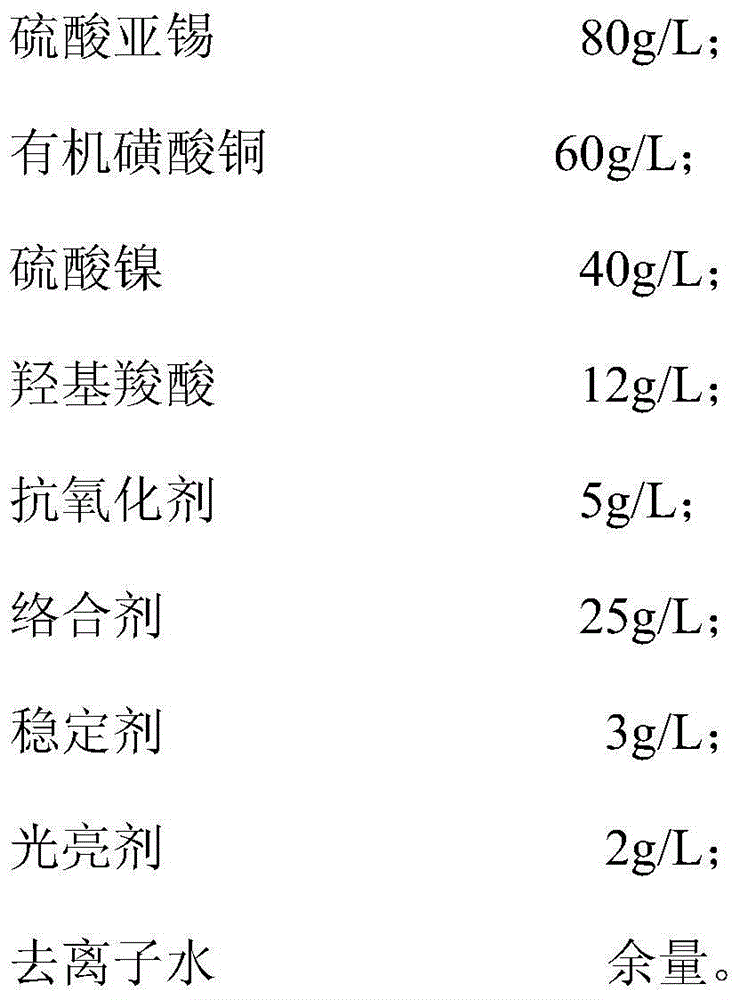

[0021] Embodiment 1: the tin-copper-nickel alloy electroplating solution of the present embodiment comprises following components:

[0022]

[0023] Use this tin-copper-nickel alloy plating solution electroplating method as follows:

[0024] Prepare tin-copper-nickel alloy electroplating solution: dissolve 25g of complexing agent, 3g of stabilizer and 5g of antioxidant in deionized water to form a solution, add 12g of hydroxycarboxylic acid, 80g of stannous sulfate, and organic sulfonic acid to the solution 60g of copper and 40g of nickel sulfate were stirred and dissolved to form a mixed solution, 2g of a brightener was added to the mixed solution to dissolve, and then the remainder of deionized water was added to a total volume of 1L to obtain a tin-copper-nickel alloy electroplating solution.

[0025] Use ammonia water to adjust the pH of the electroplating solution to 4-8, use a carbon electrode as the anode, and the workpiece as the negative electrode. The temperature ...

Embodiment 2

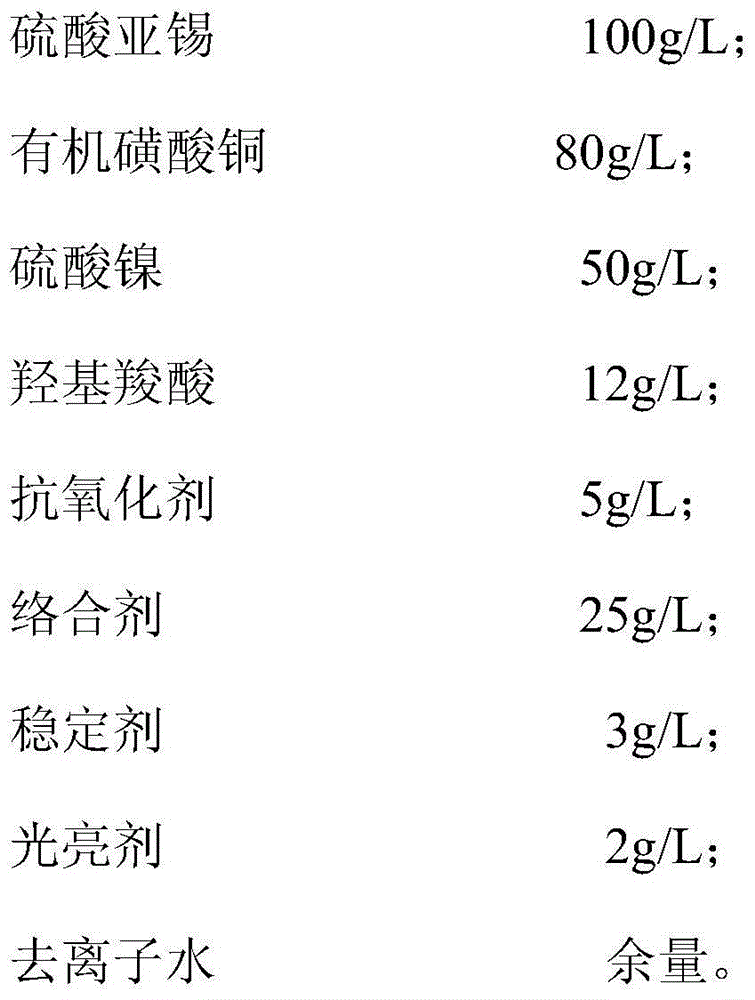

[0026] Embodiment 2: the tin-copper-nickel alloy electroplating solution of the present embodiment comprises following components:

[0027]

[0028] Use this tin-copper-nickel alloy plating solution electroplating method as follows:

[0029] Prepare tin-copper-nickel alloy electroplating solution: dissolve 25g of complexing agent, 3g of stabilizer and 5g of antioxidant in deionized water to form a solution, add 12g of hydroxycarboxylic acid, 100g of stannous sulfate, and organic sulfonic acid to the solution 80g of copper and 50g of nickel sulfate were stirred and dissolved to form a mixed solution, 2g of a brightener was added to the mixed solution to dissolve, and then the remainder of deionized water was added to a total volume of 1L to obtain a tin-copper-nickel alloy electroplating solution.

[0030] Use ammonia water to adjust the pH of the electroplating solution to 4-8, use a carbon electrode as the anode, and the workpiece as the negative electrode. The temperature...

Embodiment 3

[0031] Embodiment 3: the tin-copper-nickel alloy electroplating solution of the present embodiment comprises following components:

[0032]

[0033]

[0034] Use this tin-copper-nickel alloy plating solution electroplating method as follows:

[0035] Prepare tin-copper-nickel alloy electroplating solution: dissolve 25g of complexing agent, 3g of stabilizer and 5g of antioxidant in deionized water to form a solution, add 12g of hydroxycarboxylic acid, 150g of stannous sulfate, and organic sulfonic acid to the solution 100g of copper and 80g of nickel sulfate were stirred and dissolved to form a mixed solution, 2g of a brightener was added to the mixed solution to dissolve, and the remainder of deionized water was added to a total volume of 1L to obtain a tin-copper-nickel alloy electroplating solution.

[0036] Use ammonia water to adjust the pH of the electroplating solution to 4-8, use a carbon electrode as the anode, and the workpiece as the negative electrode. The tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com