Glass for increasing blueness of printing decorative glass based on coating method and preparation method thereof

A decorative glass, blue technology, applied in the coating and other directions, can solve problems such as low reflectivity, and achieve the effect of easy observation and increased viewing angle sensory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

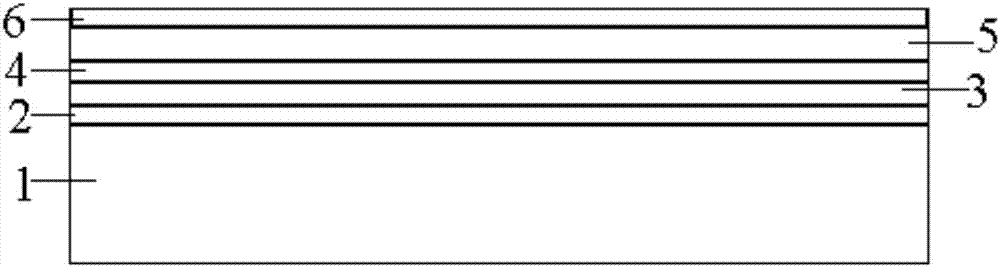

Embodiment 1

[0035] The transition film layer 2 is SiO X and TiO X Composite film layer, or SiO X and SnO X Composite film layer, x=1.7, film thickness: SiO X Film layer 5nm, TiO X Film layer 10nm, SnO X The film layer is 10nm; the metal film layer 3 is a metal Ti film layer or a NiCr alloy film layer, and the film layer thickness is 3nm; the protective film layer 4 is a silicon dioxide film layer, and the film layer thickness is 60nm.

Embodiment 2

[0037] The transition film layer 2 is SiO X and TiO X Composite film layer, or SiO X and SnO X Composite film layer, x=1.85, film thickness: SiO X Film layer 10nm, TiO X Film layer 7nm, SnO X The film layer is 7nm; the metal film layer 3 is a metal Ti film layer or a NiCr alloy film layer, and the film thickness is 5nm; the protective film layer 4 is a silicon dioxide film layer, and the film thickness is 90nm.

Embodiment 3

[0039] The transition film layer 2 is SiO X and TiO X Composite film layer, or SiO X and SnO X Composite film layer, x=1.95, film thickness: SiO X Film layer 15nm, TiO X Film layer 10nm, SnO X The film layer is 10nm; the metal film layer 3 is a metal Ti film layer or a NiCr alloy film layer, and the film thickness is 8nm; the protective film layer 4 is a silicon dioxide film layer, and the film thickness is 120nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com