Rose gold low-emissivity coated glass and preparing method and application thereof

A technology of low-radiation coating and manufacturing method, which is applied in the direction of building components, buildings, building structures, etc., can solve the problems of poor oxidation resistance, high reflectivity, and inability to store for a long time, and achieve high product yield and production process advanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Correspondingly, on the basis of the rose-gold low-emissivity coated glass described above, the embodiment of the present invention also provides a preparation method of the rose-golden low-emissivity coated glass of the embodiment of the present invention. As a preferred embodiment of the present invention, the preparation method of the rose gold low-emissivity coated glass includes the following steps:

[0038] Step S01: Pretreatment, cleaning the float glass, using the cleaned float glass as a glass substrate, and sending the cleaned float glass into a vacuum chamber, keeping the vacuum degree of the vacuum chamber at 8×10 -6 above mbar;

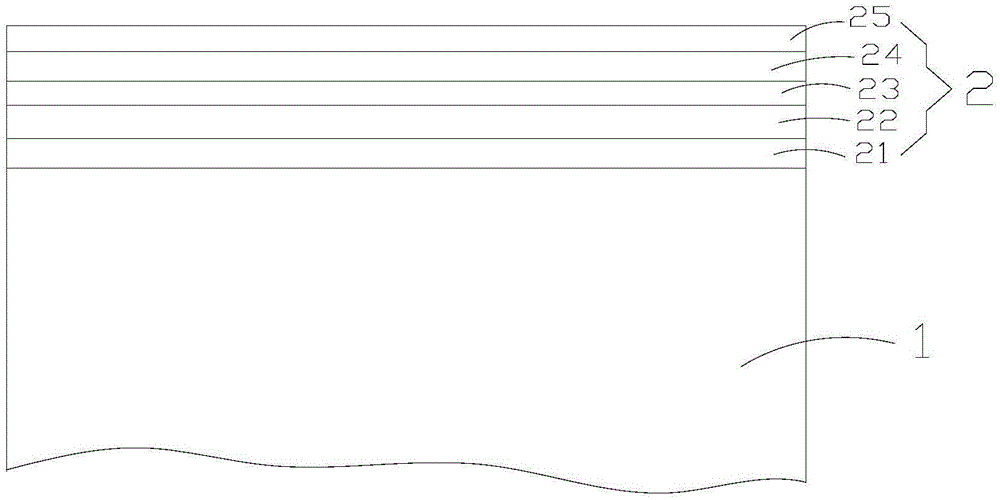

[0039] Step S02, film deposition process, control the vacuum degree of sputtering to be 2×10 -3 mbar~5×10 -3 mbar, on the float glass substrate, film layers with the following thicknesses are sequentially deposited: a first silicon nitride film layer of 10.5-32.1 nm, a zinc oxide film layer of 3.8-17.9 nm, a copper film layer of ...

Embodiment 1

[0052] A rose gold low-emissivity coated glass and a preparation method thereof. Among them, the rose gold low-emissivity coated glass includes a glass substrate and a functional film layer deposited on the surface of the glass substrate; the functional film layer at least includes a first dielectric layer and a second dielectric layer deposited layer by layer from the glass substrate outward. , a core dielectric layer, a protective layer and a third dielectric layer; where the first dielectric layer is a 28.2nm first silicon nitride film layer, the second dielectric layer is a 3.8nm zinc oxide film layer, and the core dielectric layer is a 23.2nm The copper film layer, the protective layer is a 2.9nm nickel-chromium alloy film layer, and the third dielectric layer is a 27.3nm second silicon nitride film layer; the glass substrate is float glass.

[0053] The preparation method of the rose gold low-emissivity coated glass comprises the following steps:

[0054] 1) Pre-treatme...

Embodiment 2

[0062] A rose gold low-emissivity coated glass and a preparation method thereof. Among them, the rose gold low-emissivity coated glass includes a glass substrate and a functional film layer deposited on the surface of the glass substrate; the functional film layer at least includes a first dielectric layer and a second dielectric layer deposited layer by layer from the glass substrate outward. , a core dielectric layer, a protective layer and a third dielectric layer; wherein, the first dielectric layer is a first silicon nitride film layer of 10.5nm, the second dielectric layer is a zinc oxide film layer of 7.9nm, and the core dielectric layer is a 13.2nm film layer The copper film layer, the protective layer is a 2.6nm nickel-chromium alloy film layer, and the third dielectric layer is a 10.2nm second silicon nitride film layer; the glass substrate is float glass.

[0063] The preparation method of the rose gold low-emissivity coated glass comprises the following steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com