Aluminum oxide base metal ceramic nozzle material and preparation method thereof

A ceramic nozzle and metal ceramic technology, which is applied in the field of ceramic materials to achieve the effects of low cost, good wettability and lower sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of alumina-based cermet nozzle materials:

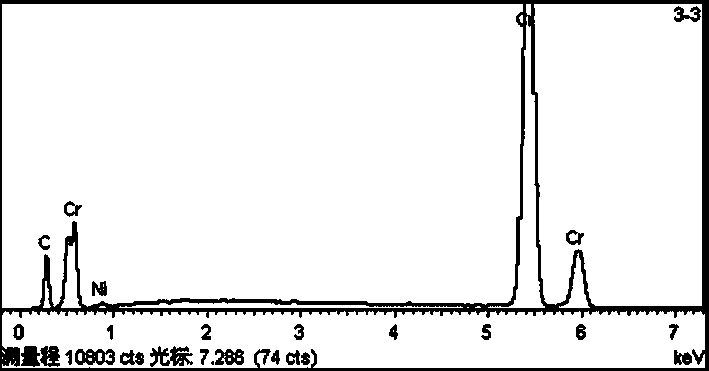

[0027] Take an appropriate amount of Ni and Cr powder and put them into a planetary ball mill tank for mechanical alloying, wherein the mass percentage of Ni is 35%, using high-purity alumina balls, the ball milling medium is absolute ethanol, the ball-to-material ratio is 5:1, and the speed is 400r / min, the ball milling time is 20 hours, then take out the slurry and put it in a vacuum oven to dry at 60°C for 24 hours; 3 C 2 NiCr powder and NiCr alloy powder were put into a ball mill and mixed for 4 hours, and the mass percentage of NiCr was 25%; they were taken out and filled in a corundum crucible, and then the filled crucible surface was sealed and then put into a vacuum microwave heating furnace. Heating and heat preservation, the heating temperature is controlled at 1000°C, the entire time of heating and heat preservation is 30 minutes, and the vacuum degree is 1.3×10 -2 Pa, figure 1 For the EDS element an...

Embodiment 2

[0030] Preparation of alumina-based cermet nozzle materials:

[0031] Take an appropriate amount of Ni and Cr powder and put them into a planetary ball mill tank for mechanical alloying, wherein the mass percentage of Ni is 45%, using high-purity alumina balls, the ball milling medium is absolute ethanol, the ball-to-material ratio is 5:1, and the speed is 400r / min, the ball milling time is 20 hours, then take out the slurry and put it in a vacuum oven to dry at 60°C for 24 hours; 3 C 2 NiCr powder and NiCr alloy powder were put into a ball mill and mixed for 4 hours, in which NiCr accounted for 20% by mass; they were taken out and filled in a corundum crucible, and then the filled crucible surface was sealed and then put into a vacuum microwave heating furnace. Heating and heat preservation, the heating temperature is controlled at 1000°C, the entire time of heating and heat preservation is 30 minutes, and the vacuum degree is 1.3×10 -2 Pa; then the above mixed powder with...

Embodiment 3

[0034] Preparation of alumina-based cermet nozzle materials:

[0035] Take an appropriate amount of Ni and Cr powder and put them into a planetary ball mill tank for mechanical alloying, wherein the mass percentage of Ni is 50%, using high-purity alumina balls, the ball milling medium is absolute ethanol, the ball-to-material ratio is 5:1, and the speed is 400r / min, the ball milling time is 20 hours, then take out the slurry and put it in a vacuum oven to dry at 60°C for 24 hours; 3 C 2 NiCr powder and NiCr alloy powder were put into a ball mill and mixed for 4 hours, and the mass percentage of NiCr was 15%; they were taken out and filled in a corundum crucible, and then the filled crucible surface was sealed and then put into a vacuum microwave heating furnace. Heating and heat preservation, the heating temperature is controlled at 1000°C, the entire time of heating and heat preservation is 30 minutes, and the vacuum degree is 1.3×10 -2 Pa; then the above mixed powder with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com