Method for preparing high-performance phosphogypsum-based self-leveling mortar

A self-leveling mortar and gypsum-based technology, applied in the field of building materials, can solve problems such as high equipment investment and sewage discharge, and achieve great social benefits, improve flatness, and improve the effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

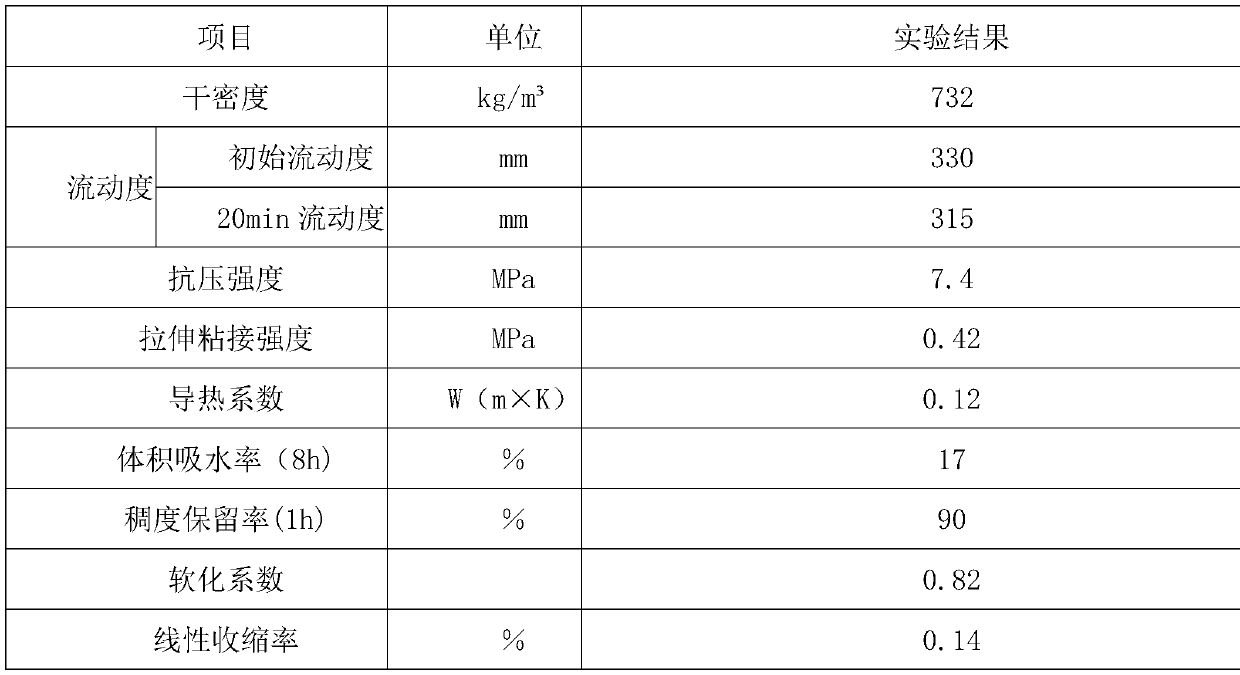

Embodiment 1

[0024] A method for preparing high-performance phosphogypsum-based self-leveling mortar, comprising the following steps:

[0025] S1, obtain raw materials, 40 parts of phosphorus building gypsum, phosphorus building gypsum comes from the calcination of phosphogypsum, 15 parts of cement, cement is ordinary Portland cement with a strength grade of 42.5 or slag Portland cement with a strength grade of 32.5, powder Coal ash 10 parts, fly ash is ordinary secondary fly ash, stone powder 3 parts, redispersible latex powder type 1.5 parts, redispersible latex powder type is one of "Wacker" 5010N or 5044N or a combination thereof , 0.05 parts of cellulose ether, 0.02 parts of carbon nanofibers, carbon nanofibers with a diameter of 50nm and a length of 50μm, 0.3 parts of water retaining agent, water retaining agent is hydroxypropyl methyl cellulose ether, viscosity range 400000-80000mpa.s, water reducer 0.1 part, 0.1 part of anti-sedimentation agent, 0.01 part of defoamer, 30 parts of f...

Embodiment 2

[0028] A method for preparing high-performance phosphogypsum-based self-leveling mortar, comprising the following steps:

[0029] S1, obtain raw materials, 50 parts of phosphorus building gypsum, phosphorus building gypsum comes from the calcination of phosphogypsum, 19 parts of cement, cement is ordinary Portland cement with a strength grade of 42.5 or slag portland cement with a strength grade of 32.5, powder Coal ash 17 parts, fly ash is ordinary secondary fly ash, stone powder 7 parts, redispersible latex powder type 2.5 parts, redispersible latex powder type is one of "Wacker" 5010N or 5044N or a combination thereof , 0.1 part of cellulose ether, 0.04 part of carbon nanofiber, diameter of carbon nanofiber is 100nm, length of 70μm, 0.5 part of water retaining agent, water retaining agent is hydroxypropyl methyl cellulose ether, viscosity range 400000-80000mpa.s, water reducer 0.8 parts, 0.3 parts of anti-sedimentation agent, 0.04 parts of defoamer, 36 parts of fine sand ag...

Embodiment 3

[0032] A method for preparing high-performance phosphogypsum-based self-leveling mortar, comprising the following steps:

[0033] S1, obtain raw materials, 60 parts of phosphorus building gypsum, phosphorus building gypsum comes from the calcination of phosphogypsum, 22 parts of cement, cement is ordinary Portland cement with a strength grade of 42.5 or slag portland cement with a strength grade of 32.5, powder Coal ash 24 parts, fly ash is ordinary secondary fly ash, stone powder 10 parts, redispersible latex powder type 4 parts, redispersible latex powder type is one of "Wacker" 5010N or 5044N or a combination thereof , 0.15 parts of cellulose ether, 0.06 parts of carbon nanofibers, carbon nanofibers with a diameter of 200nm and a length of 100μm, 0.8 parts of water retaining agent, water retaining agent is hydroxypropyl methyl cellulose ether, viscosity range 400000-80000mpa.s, water reducer 1.3 parts, 0.4 parts of anti-sedimentation agent, 0.08 parts of defoaming agent, 42...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com