High-power LED aluminum substrate integrated module

A LED aluminum substrate and integrated module technology, which is applied in cooling/heating devices of lighting devices, sustainable buildings, lighting and heating equipment, etc., can solve problems such as shortening the service life of diodes, small contact area for heat dissipation, and slow heat transfer , to achieve good structural connection reliability, good high temperature resistance, and avoid the effect of life shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

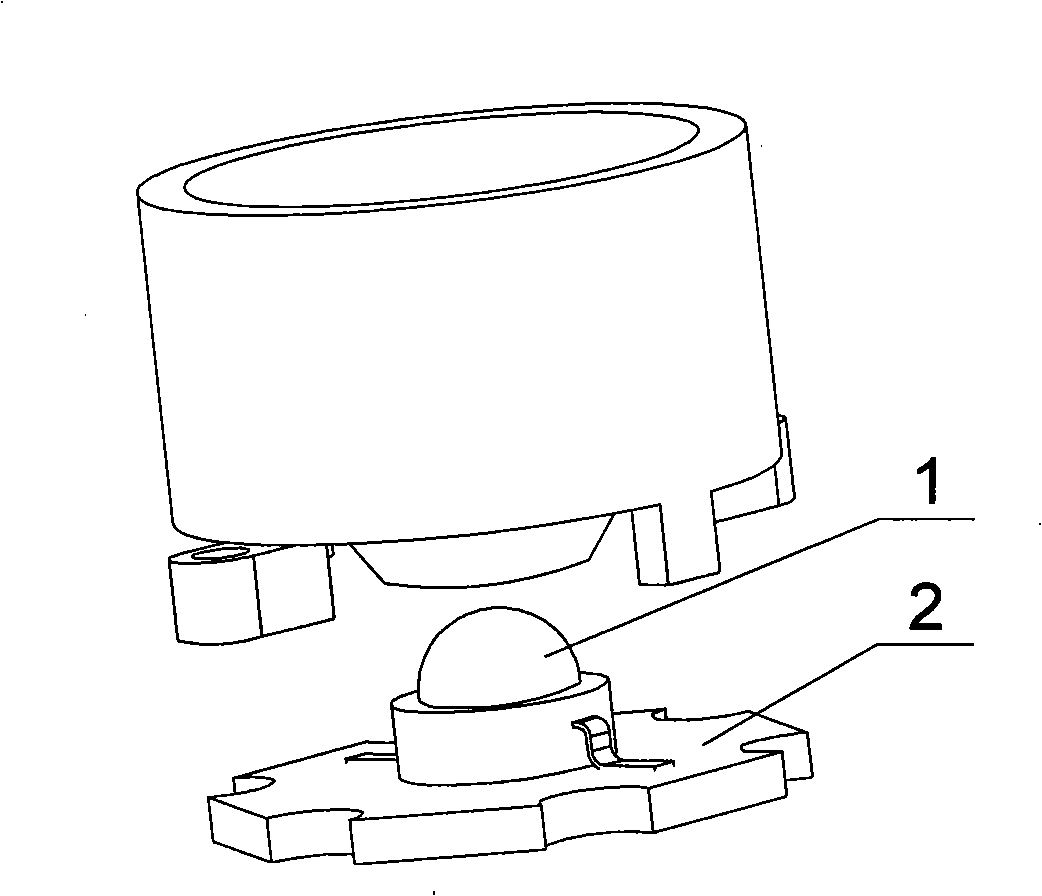

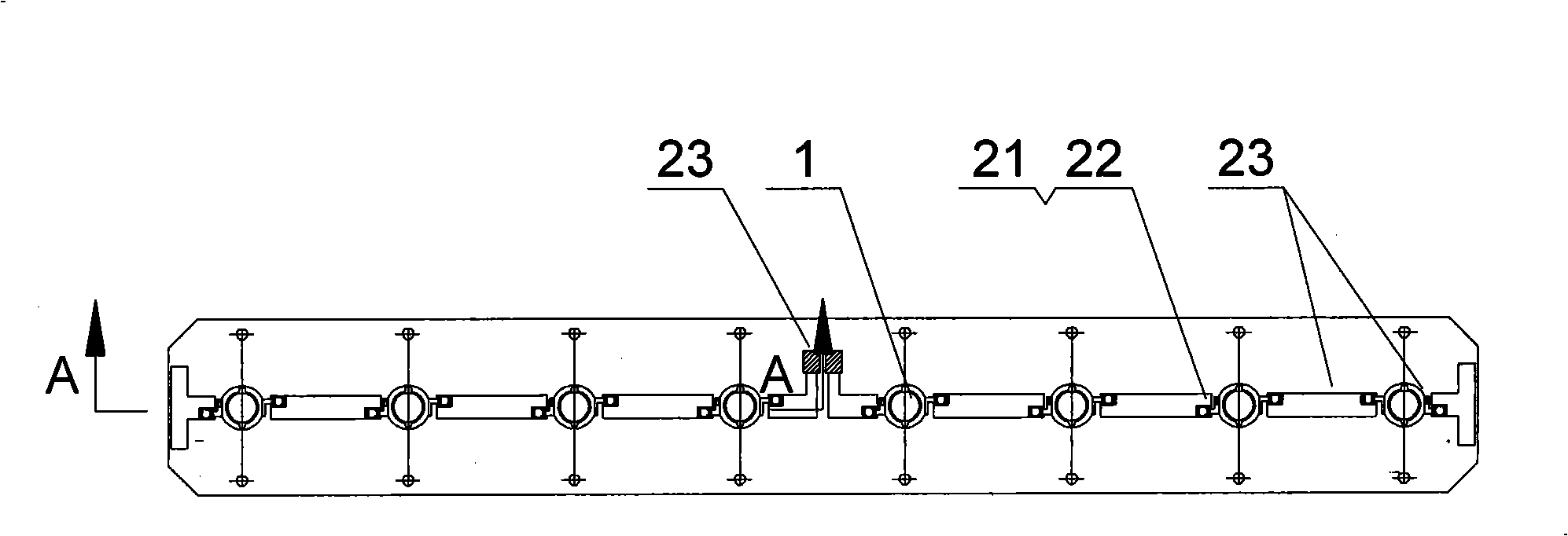

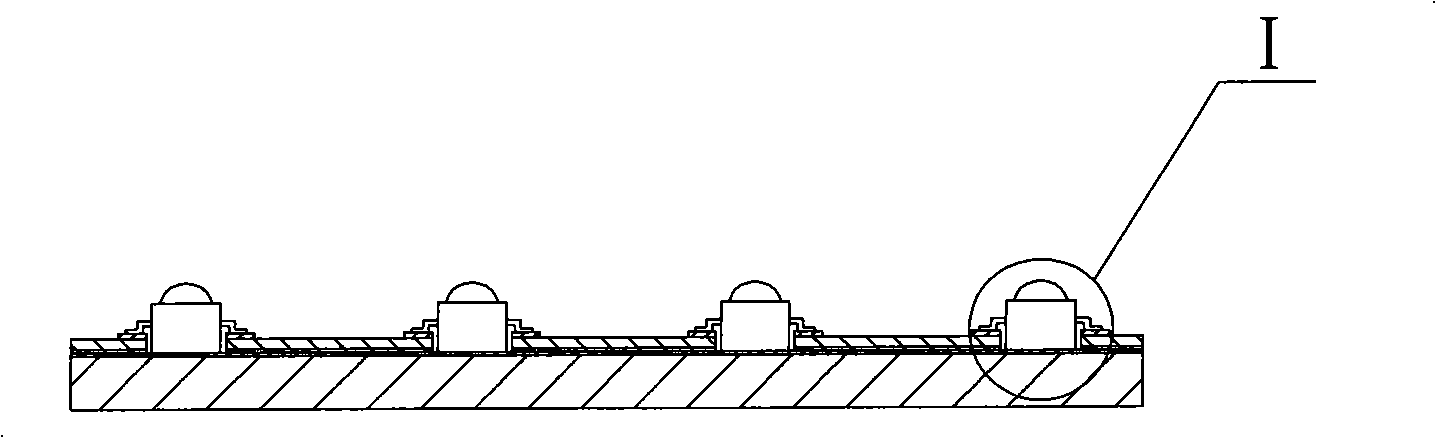

[0029] Such as Figure 2 ~ Figure 4 As shown, the present invention includes an LED 1 and an aluminum substrate 2, the aluminum substrate 2 includes an aluminum plate 20, the upper surface of the aluminum plate 20 is covered with an insulating oxide layer 25, and the insulating oxide layer 25 is sequentially provided with a base film 21, Conductive film 22, the conductive film 22 constitutes a circuit pattern, the base film 21 is adapted to the outline of the conductive film 22, the conductive film 22 is provided with a number of welding films 23, the chip of the LED 1 and the The insulating oxide layer 25 is bonded, and the pins of the LED 1 are welded on the welding film 23. The welding film 23 is also used for welding other electronic devices. The base film 21 is made of magnetron sputtering. The method deposits chromium or titanium metal on the insulating oxide layer 25, the conductive film 22 deposits copper or nickel metal on the base film 21 by magnetron sputtering, and...

Embodiment 2

[0032] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the LEDs 1 are arranged in a matrix structure. The number of LEDs 1 is larger and the integration level is higher, which is suitable for occasions with high lighting requirements.

[0033] The remaining features of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0035] Such as Figure 6 ~ Figure 8 As shown, the difference between the present embodiment and the second embodiment is that the aluminum plate 20 is a bent three-dimensional structure, the aluminum plate 20 is concave with several folded edges, the LED 1 is arranged on the folded edges, each The included angles between the folded edges are θ1, θ2, θ3, θ1′, θ2′, θ3′ respectively, and by changing different angles of the included angles, each of the LEDs 1 can be realized to emit light in different directions to meet actual needs glow effect. This embodiment can be installed on the radiator or the lamp housing 6 through the heat conducting glue 8, and the heat dissipation effect is better. The installation structure is as follows: Figure 8 shown.

[0036] The other features of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com