Preparation method of PERC battery as well as double-faced selective emitter PERC battery

An emitter, selective technology, applied in circuits, electrical components, climate sustainability, etc., can solve problems such as the inability to achieve good double-sided battery back printing, poor product results, and inability to achieve mass production. The cost of equipment and materials is limited, the yield is high, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

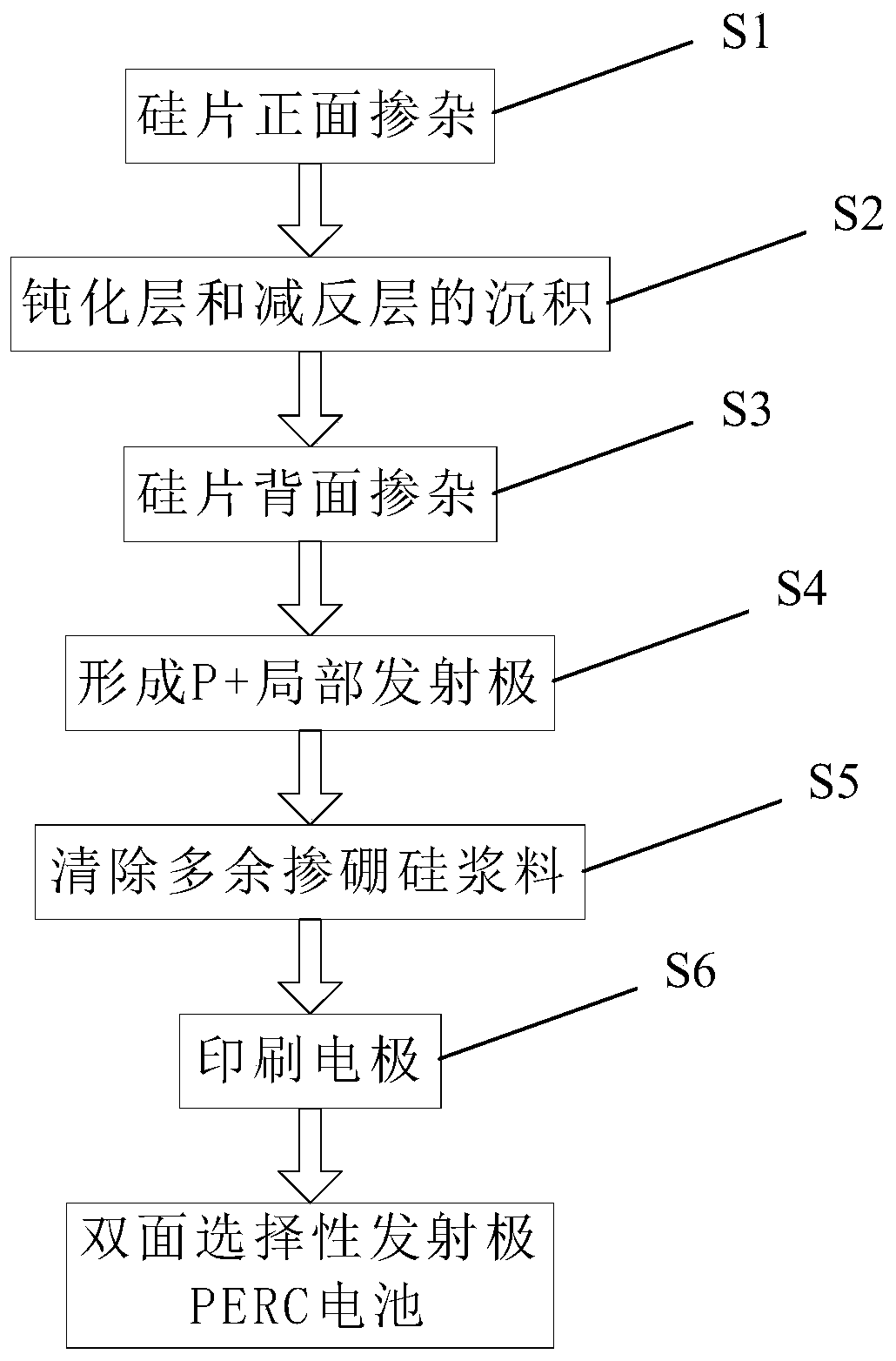

[0040] Such as figure 1 As shown, a method for preparing a double-sided selective emitter PERC battery in this embodiment includes the following steps:

[0041] Step S1: Front side doping of silicon wafer

[0042] Select P-type monocrystalline silicon wafers, first perform pre-cleaning and surface texturing, and then use low-pressure or normal-pressure diffusion furnaces to lightly dope phosphorus elements on the front to form N+ lightly doped regions. The doping concentration of N+ lightly doped regions is 3*E+20 / cm 3 , The square resistance is 120Ω / port.

[0043] The laser is used to heavily dope the front side of the silicon wafer to form a local N++ heavily doped region, and the doping concentration of the N++ heavily doped region is 2*E+20 / cm 3 , The sheet resistance is 70Ω / port.

[0044]The parameters of the laser in this step are as follows: the laser is a 532nm green laser, the laser power is 30W, the laser frequency is 250KHz, the laser running speed is 13m / s, and...

Embodiment 2

[0064] Such as figure 1 As shown, a method for preparing a double-sided selective emitter PERC battery in this embodiment includes the following steps:

[0065] Step S1: Front side doping of silicon wafer

[0066] Select P-type monocrystalline silicon wafers, first perform pre-cleaning and surface texturing, and then use a low-pressure or normal-pressure diffusion furnace to lightly dope phosphorus elements on the front to form an N+ lightly doped region. The doping concentration of the N+ lightly doped region is 1*E+20 / cm 3 , The square resistance is 110Ω / port.

[0067] The laser is used to heavily dope the front side of the silicon wafer to form a local N++ heavily doped region, and the doping concentration of the N++ heavily doped region is 2*E+20 / cm 3 , The square resistance is 50Ω / port.

[0068] The parameters of the laser in this step are as follows: the laser is a 532nm green laser, the laser power is 25W, the laser frequency is 200KHz, the laser running speed is 10...

Embodiment 3

[0088] Such as figure 1 As shown, a method for preparing a double-sided selective emitter PERC battery in this embodiment includes the following steps:

[0089] Step S1: Front side doping of silicon wafer

[0090] Select P-type monocrystalline silicon wafers, first perform pre-cleaning and surface texturing, and then use a low-pressure or normal-pressure diffusion furnace to lightly dope phosphorus elements on the front to form an N+ lightly doped region. The doping concentration of the N+ lightly doped region is 6*E+20 / cm 3 , The square resistance is 140Ω / port.

[0091] The laser is used to heavily dope the front side of the silicon wafer to form a local N++ heavily doped region, and the doping concentration of the N++ heavily doped region is 4*E+20 / cm 3 , The square resistance is 80Ω / port.

[0092] The parameters of the laser in this step are as follows: the laser is a 532nm green laser, the laser power is 40W, the laser frequency is 300KHz, the laser running speed is 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com