Lithium supplement additive for lithium ion cathode material and preparation method thereof

A positive electrode material and additive technology, which is applied in the field of high stability lithium ion positive electrode material lithium supplementary additive and its preparation, can solve the problem of difficulty in uniformly controlling the distribution of coating elements and coating thickness, limited effect of isolating corrosion, and reduced coating effect. and other problems, to achieve the effect of improving the electrochemical performance and the lithium supplementation performance of the positive electrode, improving the electrical conductivity, and improving the degree of bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

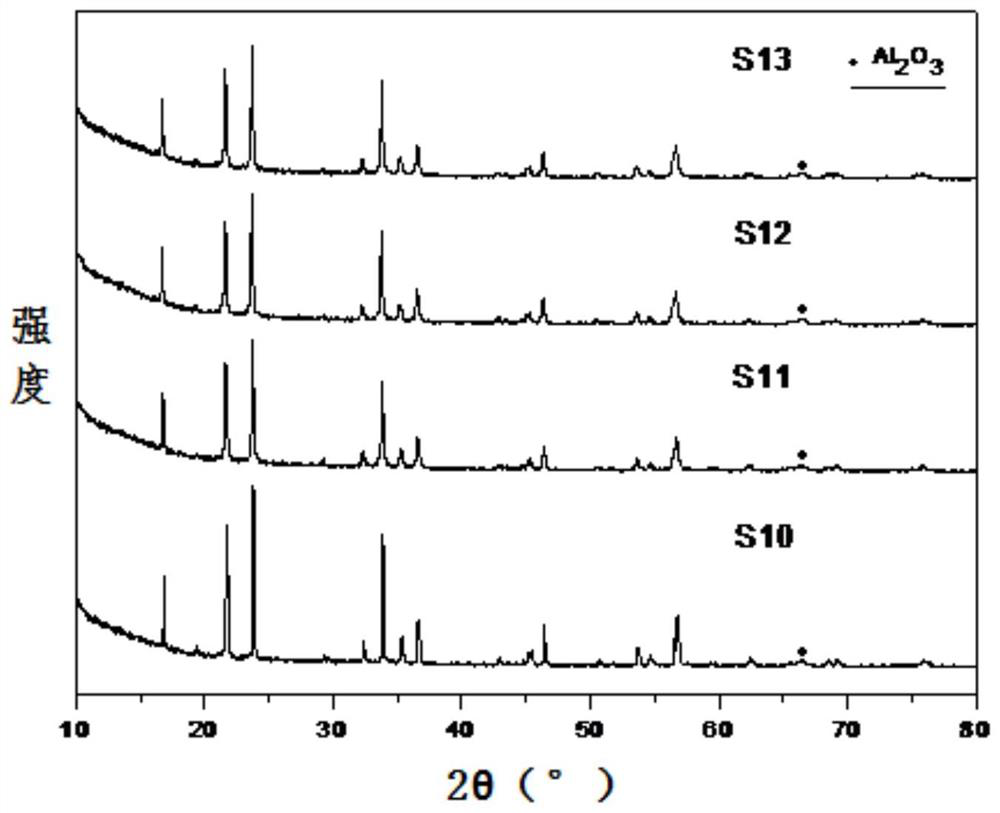

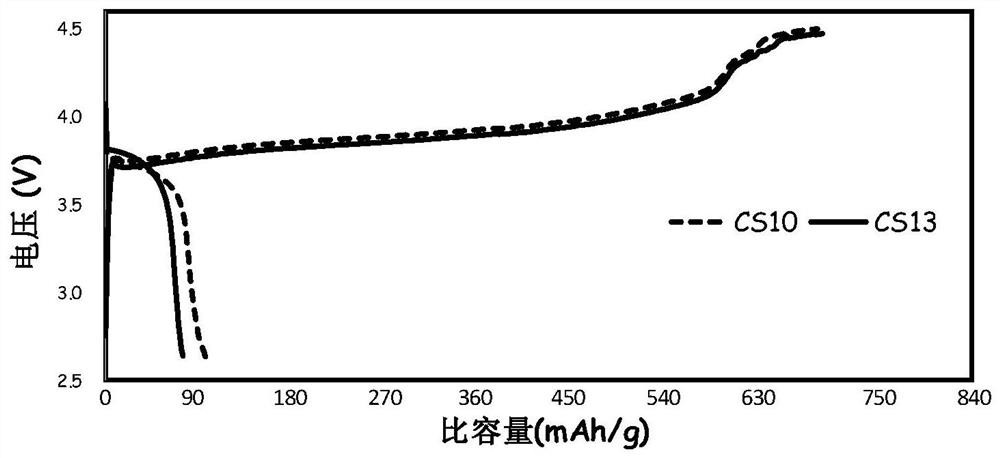

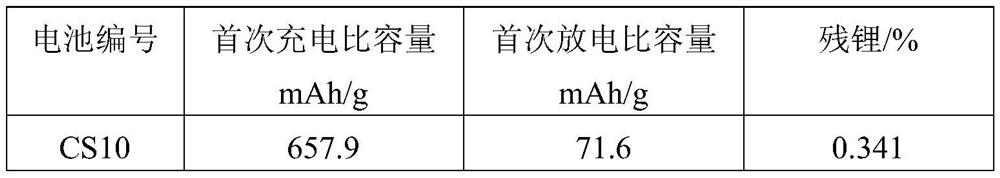

[0037] A kind of lithium ion cathode material supplement lithium additive of the present invention, comprises Li 5 FeO 4 matrix, located at Li 5 FeO 4 The first cladding layer carbon layer on the surface of the substrate and the second cladding layer alumina layer on the surface of the first cladding layer; wherein, the quality of the carbon layer is Li 5 FeO 4 2.3 wt% of the mass of the substrate; the alumina layer relative to the Li 5 FeO 4 3.3 wt% of the matrix mass.

[0038] The preparation method of the lithium ion cathode material lithium supplement additive of the present embodiment comprises the following steps:

[0039] (1) Carbon-coated iron oxide material preparation:

[0040] 1.1) Make 100mL concentration 0.5mol L -1The ferric sulfate solution was added to the ammonium hydroxide solution with a concentration of 2mol L-1, and after magnetic stirring and dispersion for 30 minutes (stirring speed was 450rpm / min), ultrasonic treatment was performed for 20 minut...

Embodiment 2

[0052] A kind of lithium ion cathode material supplement lithium additive of the present invention, comprises Li 5 FeO 4 matrix, located at Li 5 FeO 4 The first cladding layer carbon layer on the surface of the substrate and the second cladding layer titanium oxide layer positioned on the surface of the first cladding layer; wherein, the quality of the carbon layer is Li 5 FeO 4 4.7 wt% of the mass of the substrate; TiO layer relative to Li 5 FeO 4 5.2 wt% of the matrix mass.

[0053] The preparation method of the lithium ion cathode material lithium supplement additive of the present embodiment comprises the following steps:

[0054] (1) Carbon-coated iron oxide material preparation:

[0055] 1.1) Make 100mL concentration 0.5mol L -1 The ferric chloride solution is added to a concentration of 3mol L -1 In the ammonium hydroxide solution, disperse with magnetic stirring for 40 minutes (stirring speed is 400rpm / min), sonicate for 15 minutes, let stand until the reddish...

Embodiment 3

[0067] A kind of lithium ion cathode material supplement lithium additive of the present invention, comprises Li 5 FeO 4 matrix, located at Li 5 FeO 4 The first cladding layer carbon layer on the surface of the substrate and the second cladding layer zirconia layer positioned on the surface of the first cladding layer; wherein, the quality of the carbon layer is Li 5 FeO 4 1.2 wt% of matrix mass; zirconia relative to Li 5 FeO 4 5.3 wt% of the matrix mass.

[0068] The preparation method of the lithium ion cathode material lithium supplement additive of the present embodiment comprises the following steps:

[0069] (1) Carbon-coated iron oxide material preparation:

[0070] 1.1) Dilute 150mL concentration to 1mol L -1 The ferric nitrate solution was added to a concentration of 2mol L -1 In the ammonium hydroxide solution, after magnetic stirring and dispersion for 30 minutes (stirring speed is 400rpm / min), sonicate for 20 minutes, let it stand until the reddish-brown p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com