Low-carbon magnesia carbon brick containing nanometer zinc oxide

A technology of nano-zinc oxide and carbon-magnesia-carbon bricks, which is applied in the field of refractory materials, can solve problems such as poor density and oxidation resistance, lower high-temperature performance of magnesia-carbon bricks, and difficulty in dispersion, so as to improve room temperature and high temperature performance and improve ceramic bonding. degree, the effect of increasing the diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

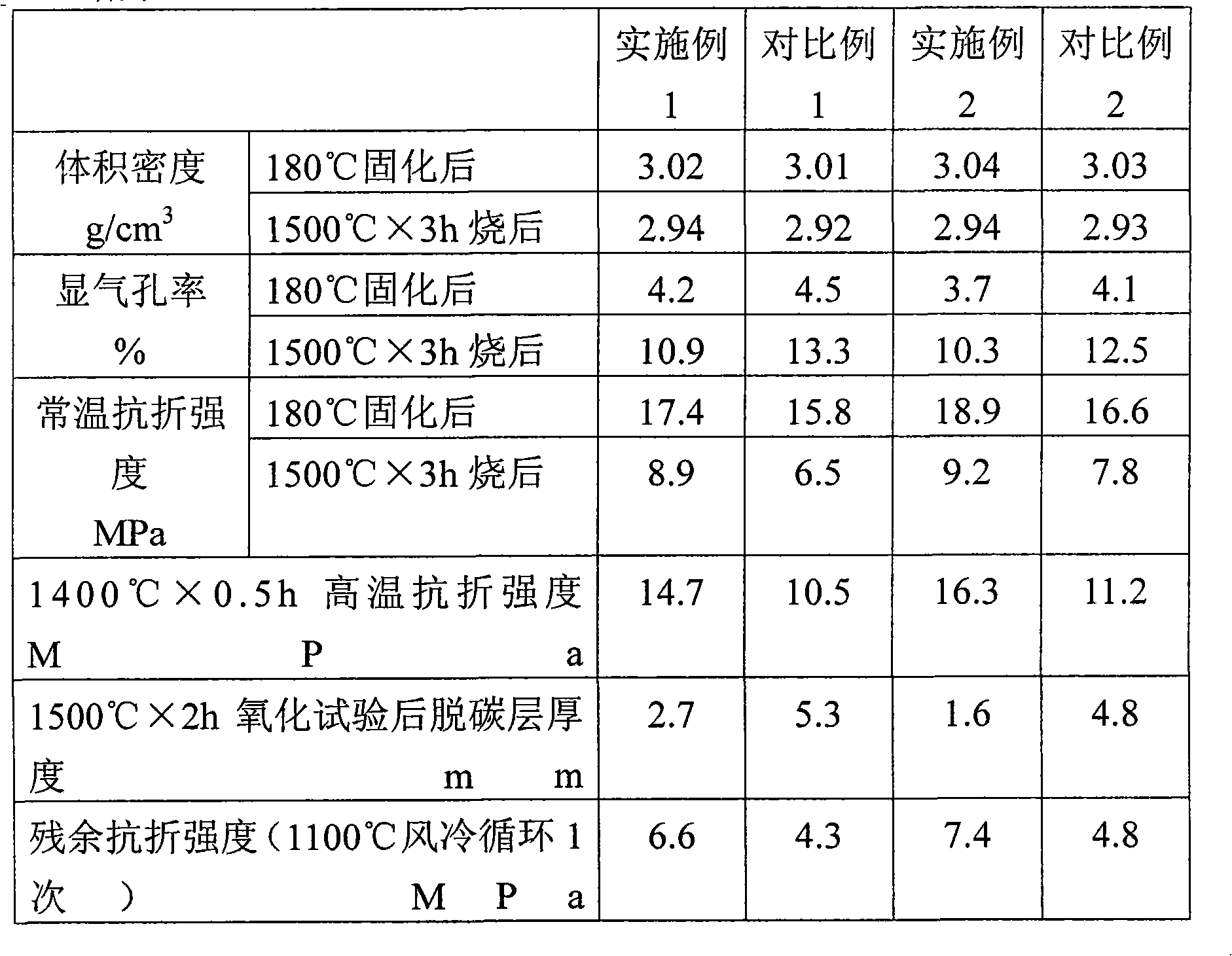

Embodiment 1

[0021] Get by weight percentage: fused magnesia 90.5wt% (wherein the particle of ≤ 6mm is 70wt%, the fine powder 30wt% of ≤ 0.074mm), flake graphite 5wt%, metal Al 3wt%, nanometer zinc oxide 1.5wt% mixes; Then add 4wt% thermosetting phenolic resin which is the sum of the weight percentages of the above four raw materials for kneading, use a press to form, the forming pressure is 250MPa, and the mixture is cured at 180°C for 24h.

Embodiment 2

[0024] Get by weight percent: fused magnesia 91wt% (wherein the particle of ≤ 6mm is 68wt%, the fine powder 32wt% of ≤ 0.074mm), flake graphite 3wt%, metal Al 2wt%, nano-zinc oxide 4wt% mixes, then Add 3.5wt% thermosetting phenolic resin which is the sum of the weight percentages of the above four raw materials for kneading, use a press to form, the forming pressure is 250MPa, and cure at 180°C for 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com