Through hole forming method

A dielectric layer and anti-reflection layer technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven distribution of polymers, rough side walls, pollution, etc., and achieve uniform resistance distribution and smooth side walls , clear edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

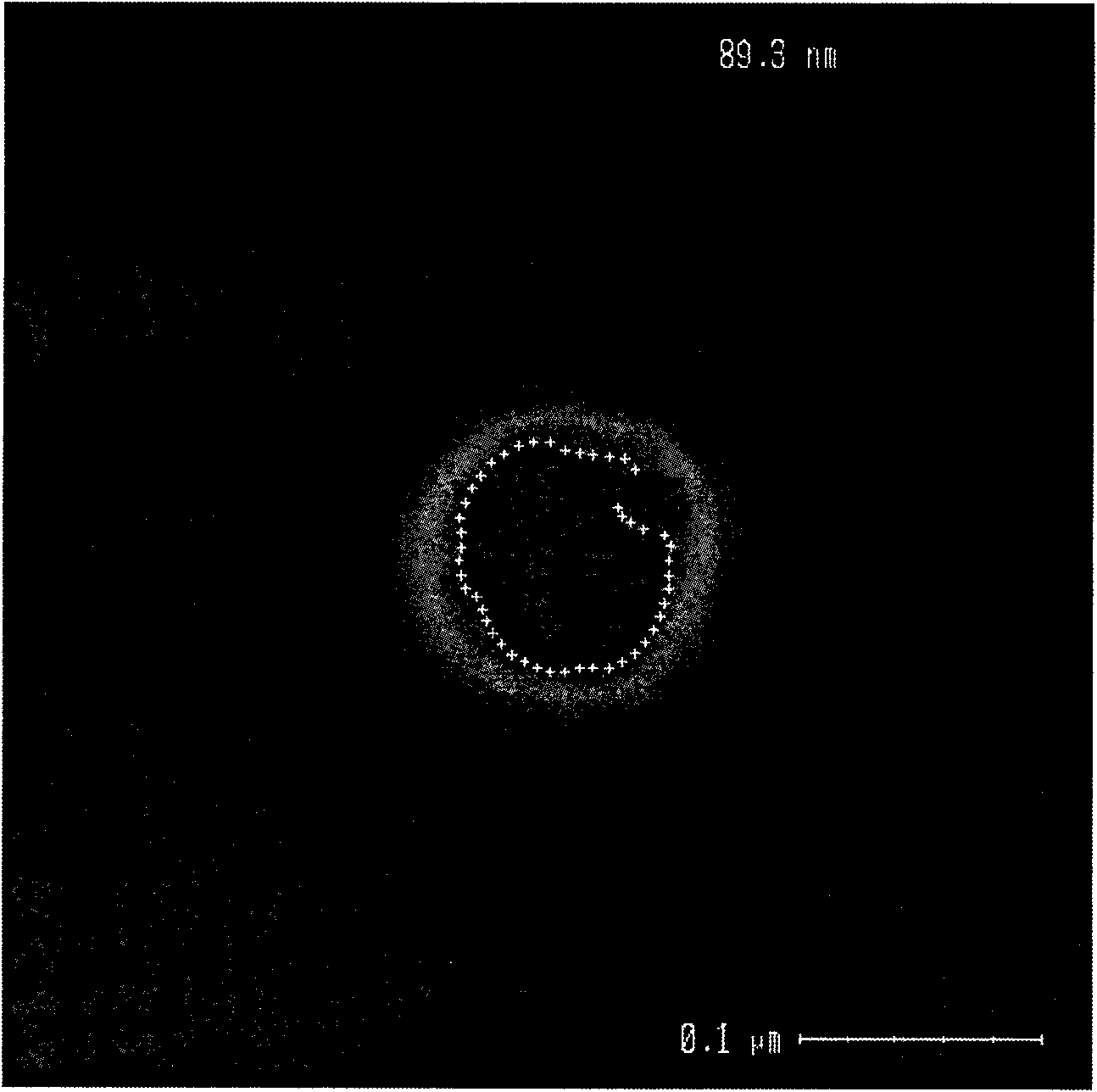

Image

Examples

Embodiment Construction

[0033] In order to make the purpose and features of the present invention more obvious and understandable, the present invention will be further described by giving preferred embodiments and in conjunction with the accompanying drawings.

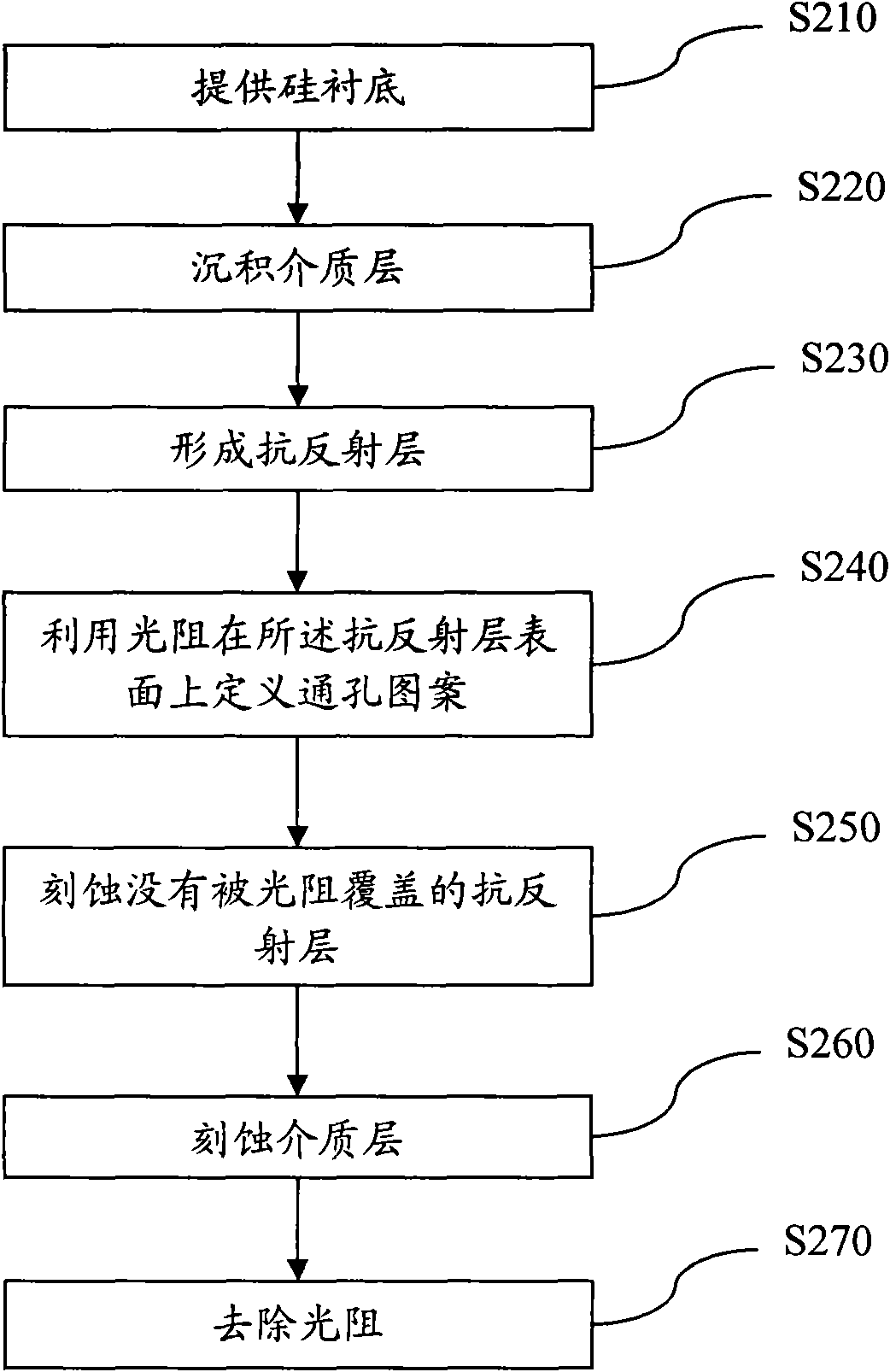

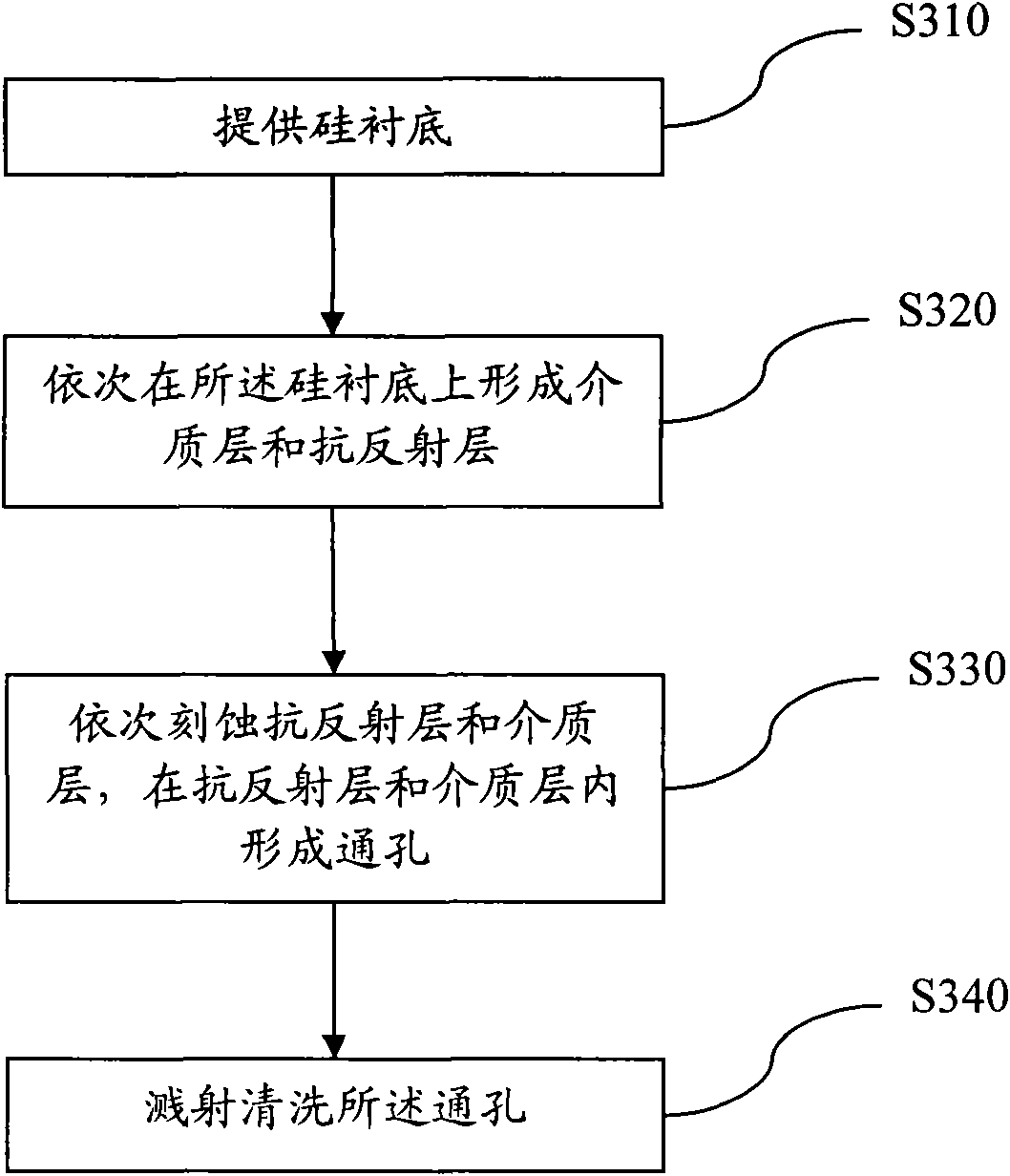

[0034] See image 3 , which shows a method for forming a through hole provided by an embodiment of the present invention. The method comprises the following steps:

[0035] S310: providing a silicon substrate;

[0036] S320: sequentially forming a dielectric layer and an anti-reflection layer on the silicon substrate; forming a dielectric layer on the silicon substrate for forming a through hole, in this embodiment, the dielectric layer for forming a through hole is an oxide silicon layer, the thickness of which is to between, for example An anti-reflection layer is formed on the above-mentioned medium layer for forming a pattern thereon, and a through-hole pattern is defined on the surface of the anti-reflection layer by using a pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com