Touch screen panel

A touch screen and panel technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of increased resistance, poor durability, high cost of ITO layer preparation, etc., to achieve enhanced conductivity and improved durability performance, sensitivity and accuracy enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The touch screen panel provided by the present invention and the manufacturing method thereof will be further described in detail below with reference to the accompanying drawings and specific embodiments.

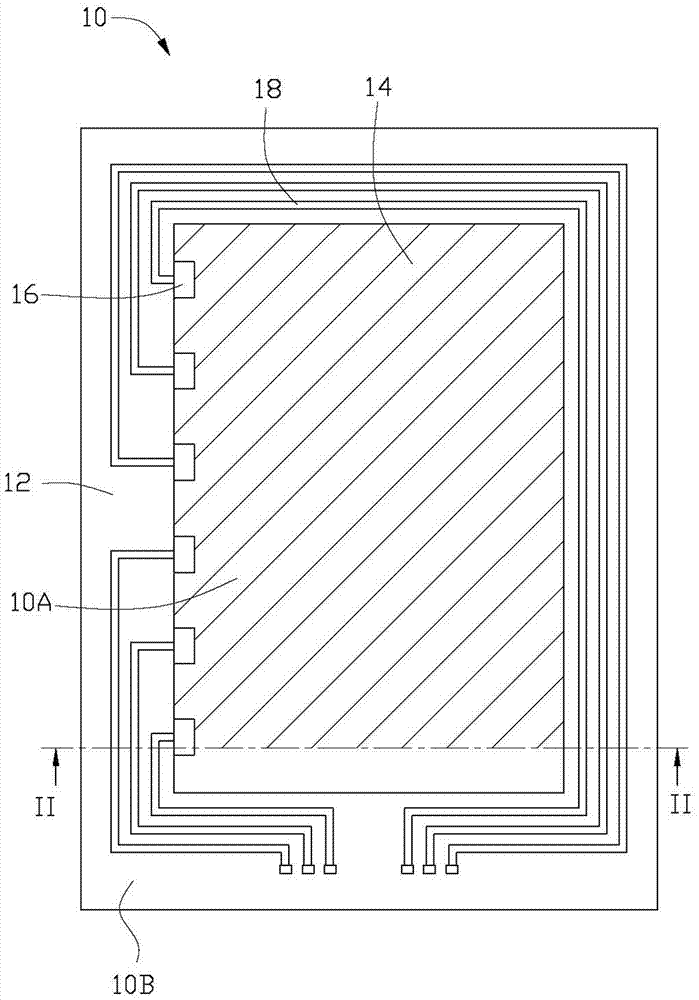

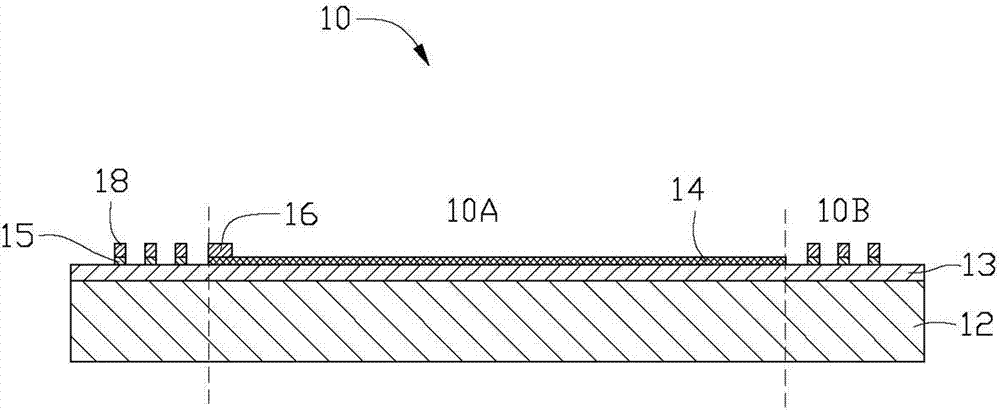

[0023] see figure 1 and figure 2 , the embodiment of the present invention provides a touch screen panel 10 , the touch screen panel 10 includes an insulating substrate 12 , an adhesive layer 13 , a transparent conductive layer 14 , at least one electrode 16 , and a conductive circuit 18 .

[0024] The touch screen panel 10 defines two areas: a touch area 10A and a wiring area 10B. The touch area 10A is an area where the touch screen panel 10 can be touched to realize a touch function, and the wiring area 10B is an area where the conductive lines 18 in the touch screen panel 10 are disposed. The wiring area 10B is a small area near the edge of the touch screen panel 10 , which may be located on at least one side of the touch area 10A. The touch area 10A is a rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com