Electrical-conductivity polyurethane charging roller and preparation method thereof

A technology of polyurethane and electrical conductivity, applied in the field of conductive polyurethane charging roller and its preparation, can solve the problems of short service life, poor conductivity, poor mechanical properties and durability, etc., and achieve long service life, excellent processing performance and good mechanical performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

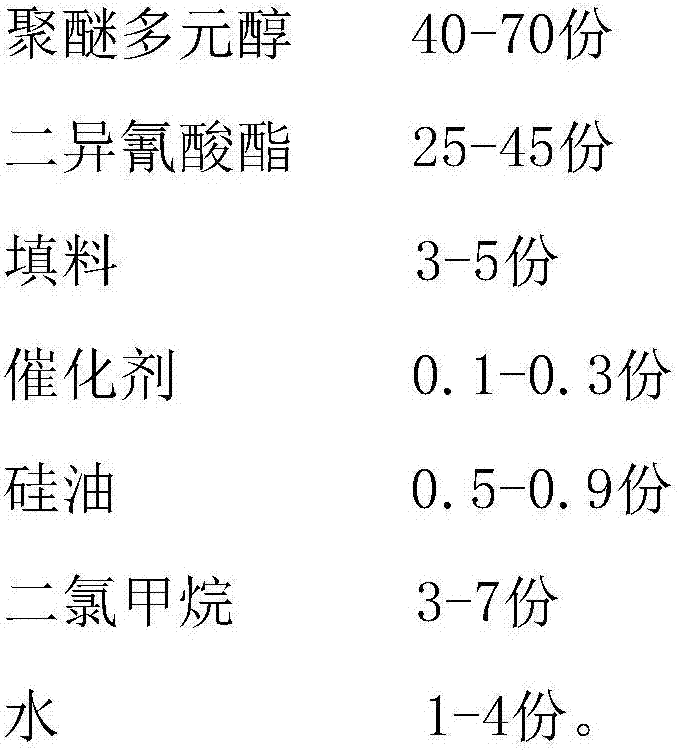

[0032] A conductive polyurethane charging roller, comprising a roller shaft, a conductive polyurethane layer sleeved on the outside of the roller shaft; the conductive polyurethane layer is made of the following raw materials in parts by weight:

[0033]

[0034] The polyether polyol is a propylene glycol polyether with a molecular weight of 1200.

[0035] The polyether polyol has a functionality of 2, a hydroxyl value of 40 mgKOH / g, an acid value of 0.6 mgKOH / g, an amine value of 6 mgKOH / g, a dynamic viscosity of 4500 mPa.s, and a water content of ≤0.1%.

[0036] The isocyanate is toluene-2,4-diisocyanate.

[0037] The filler is heavy calcium carbonate with a particle size of 100 μm and treated with higher fatty acid salts.

[0038] The catalyst is composed of stannous octoate and A33 catalyst with a weight ratio of 8:2.

[0039] The silicone oil is methyl silicone oil, ethyl silicone oil or phenyl silicone oil.

[0040] A preparation method of a conductive polyurethane...

Embodiment 2

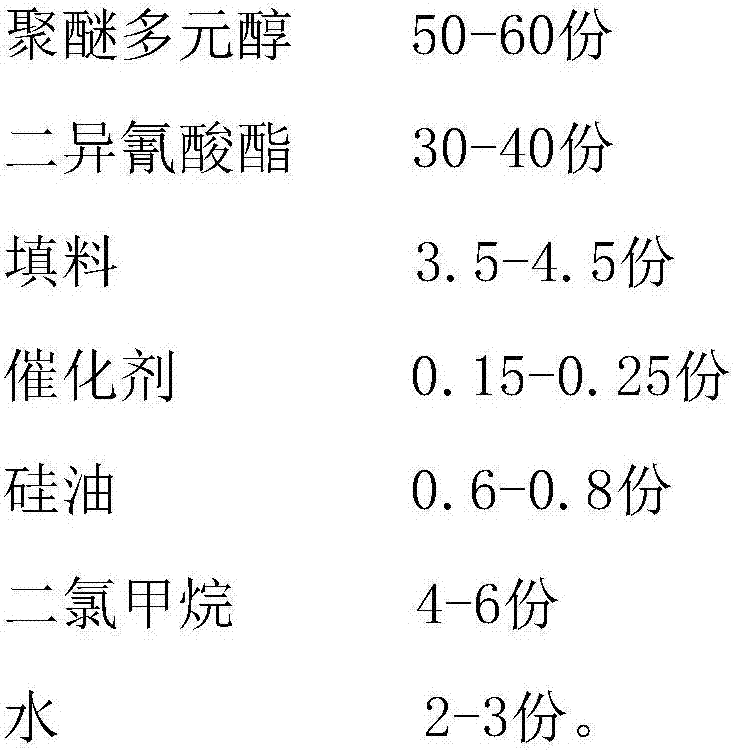

[0045] The difference between this embodiment and the above-mentioned embodiment 1 is that the conductive polyurethane layer is made of the following raw materials in parts by weight:

[0046]

[0047] The polyether polyol is a trimethylolpropane polyether with a molecular weight of 1000.

[0048] The polyether polyol has a functionality of 3, a hydroxyl value of 45 mgKOH / g, an acid value of 0.7 mgKOH / g, an amine value of 7 mgKOH / g, a dynamic viscosity of 4800 mPa.s, and a water content of ≤0.1%.

[0049] The isocyanate is toluene-2,4-diisocyanate.

[0050] The filler is heavy calcium carbonate with a particle size of 200 μm and treated with higher fatty acid salts.

[0051] The catalyst is composed of stannous octoate and A33 catalyst with a weight ratio of 8:2.5.

[0052] The silicone oil is methyl hydrogen silicone oil or methyl phenyl silicone oil.

Embodiment 3

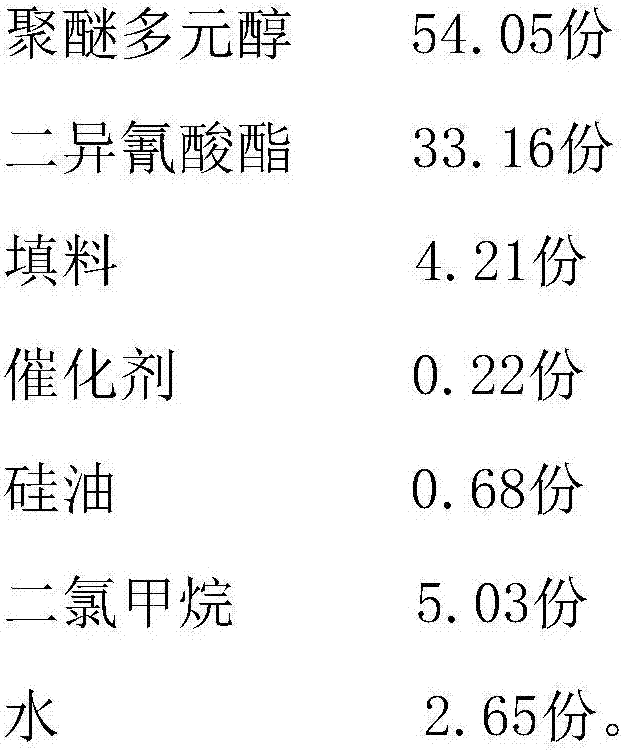

[0054] The difference between this embodiment and the above-mentioned embodiment 1 is that the conductive polyurethane layer is made of the following raw materials in parts by weight:

[0055]

[0056] The polyether polyol is hydroxyl-terminated polytetrahydrofuran.

[0057] The polyether polyol has a functionality of 3, a hydroxyl value of 50 mgKOH / g, an acid value of 0.8 mgKOH / g, an amine value of 8 mgKOH / g, a dynamic viscosity of 5000 mPa.s, and a water content of ≤0.1%.

[0058] The isocyanate is toluene-2,4-diisocyanate.

[0059] The filler is heavy calcium carbonate with a particle size of 300 μm and treated with higher fatty acid salts.

[0060] The catalyst is composed of stannous octoate and A33 catalyst with a weight ratio of 8:3.

[0061] The silicone oil is methyl chlorophenyl silicone oil or methyl ethoxy silicone oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com