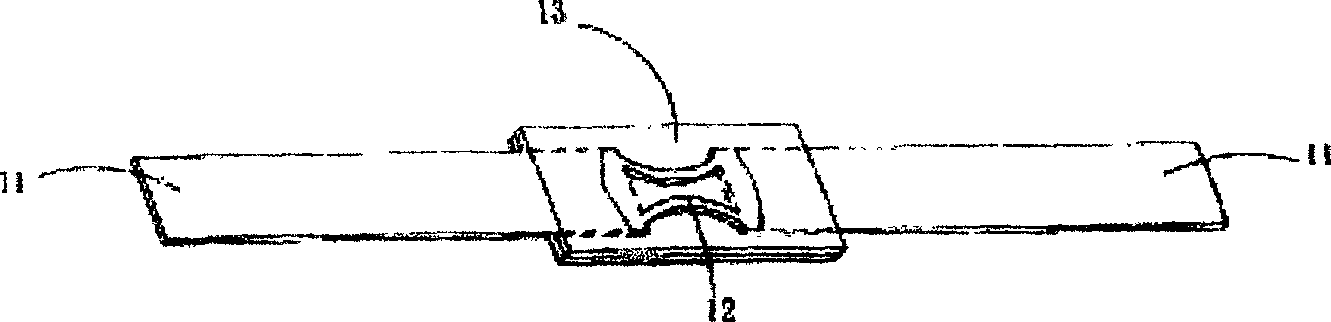

Method for mfg. alloy type temp fuse

A technology for thermal fuses and manufacturing methods, applied in emergency protection devices, electrical components, circuits, etc., can solve problems such as uneven distribution of product resistance, adhesion of low-melting point alloys and welding heads, and difficulty in accurately controlling the melting part, etc., to achieve continuous operation Good performance and stability, reduced complexity, uniform distribution of product resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

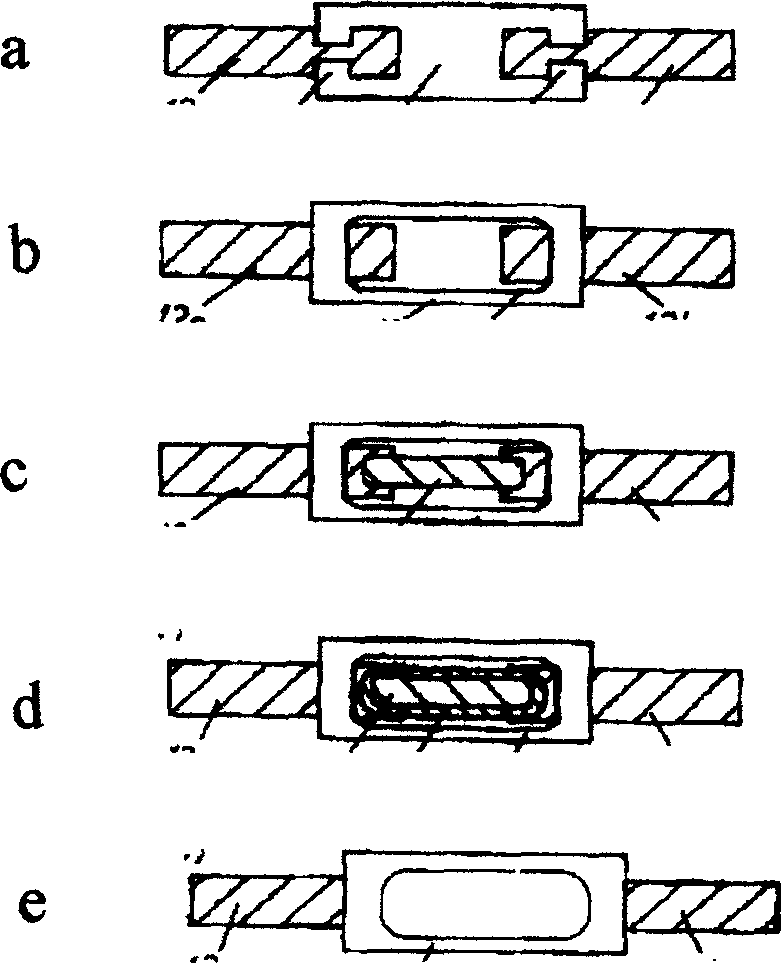

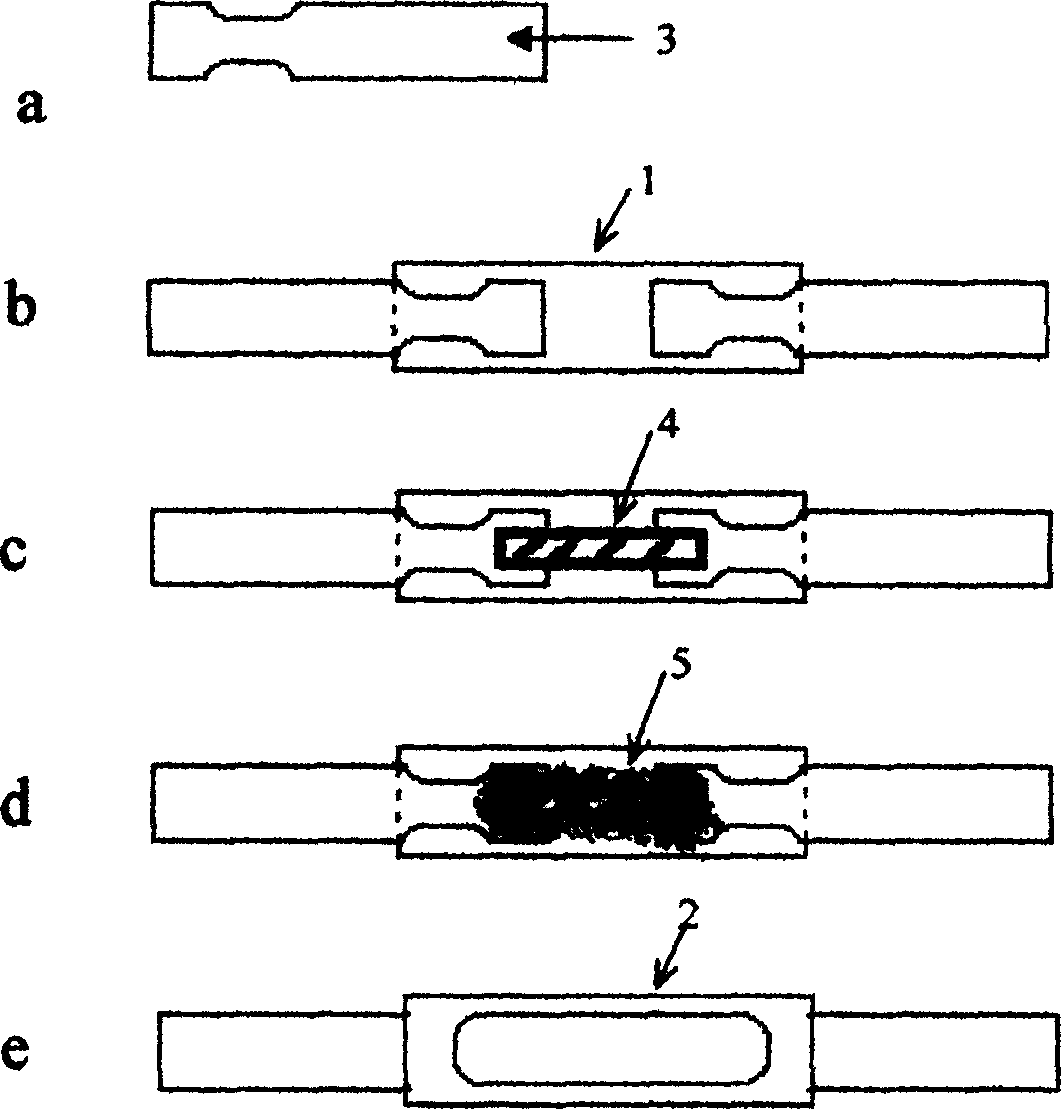

Method used

Image

Examples

Embodiment 1

[0046] When connecting the low-melting-point alloy wire and the electrode connection sheet, a metal welding head coated with a polytetrafluoroethylene layer is used for cold-press welding. The part where one end of the electrode connection sheet is connected with the low melting point alloy wire is plated with a metal copper layer.

Embodiment 2

[0048] When connecting the low-melting-point alloy wire and the electrode connecting sheet, a non-metallic material bakelite welding head is used for cold-press welding. The part where one end of the electrode connection sheet is connected with the low melting point alloy wire is plated with a metal copper layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com