P-type tunneling oxide passivated contact solar cell and preparation method thereof

A technology of solar cells and oxides, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor passivation effect on the back of solar cells, and achieve excellent interface passivation effect, high conversion efficiency, and high temperature stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] A method for preparing a P-type tunnel oxide passivation contact solar cell, the preparation of the P-type tunnel oxide passivation contact solar cell comprises the following steps:

[0041] S1. First remove the damaged layer of the silicon wafer and then use the alkali texturing process to form a pyramid textured surface with a height of 0.5 μm-5 μm;

[0042] S2, using phosphorus oxychloride (POCl 3 ) high-temperature diffusion, the reaction temperature is 750-850°C, and the reaction time is 30-60min, forming a P-doped N+ emitter junction on the surface of the silicon wafer, that is, an N-type heavily doped silicon layer, and forming a phosphosilicate glass (PSG) layer at the same time.

[0043] S3, cleaning the silicon wafer surface;

[0044] S31, using HF solution to remove the phosphosilicate glass (PSG) layer on the surface of the silicon wafer;

[0045] S32, using the RCA wet chemical method to clean the surface of the silicon wafer;

[0046] S4, using low-pres...

Embodiment 1

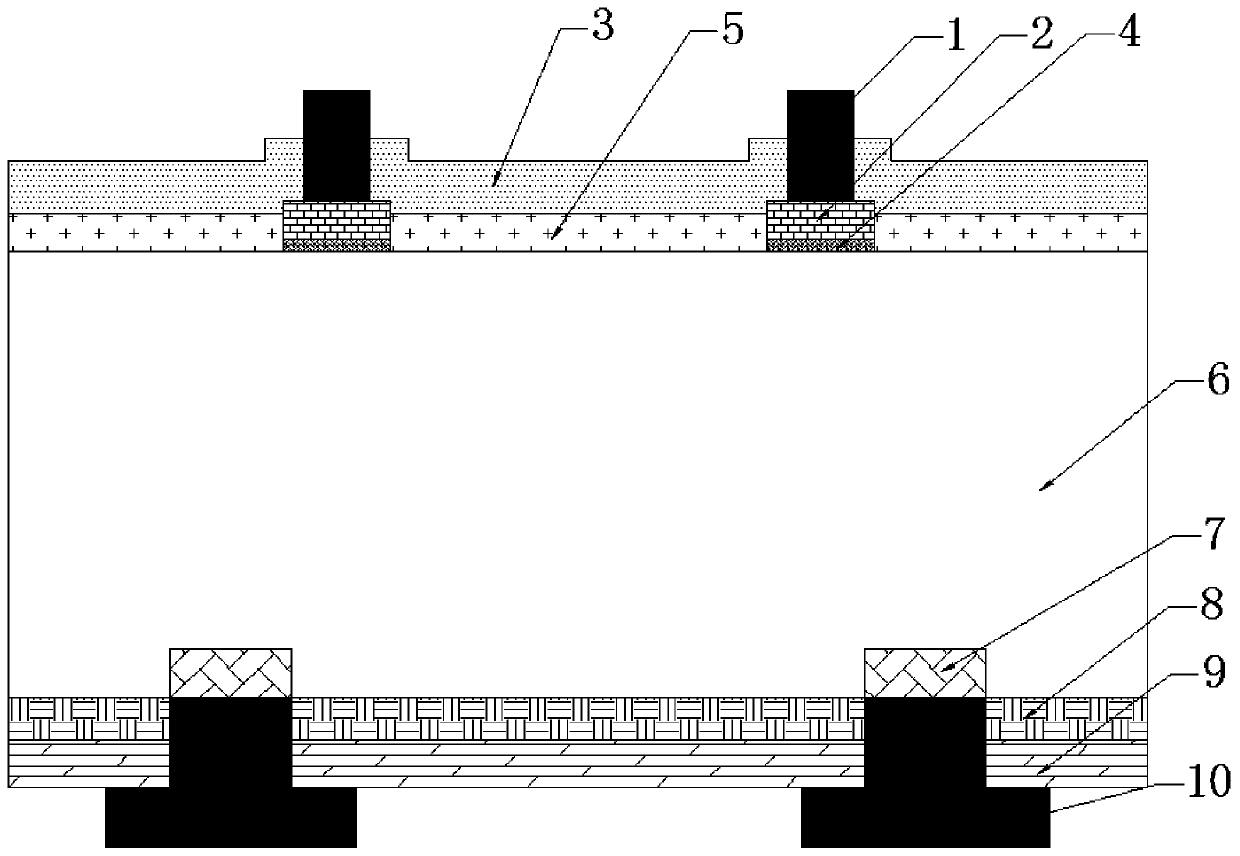

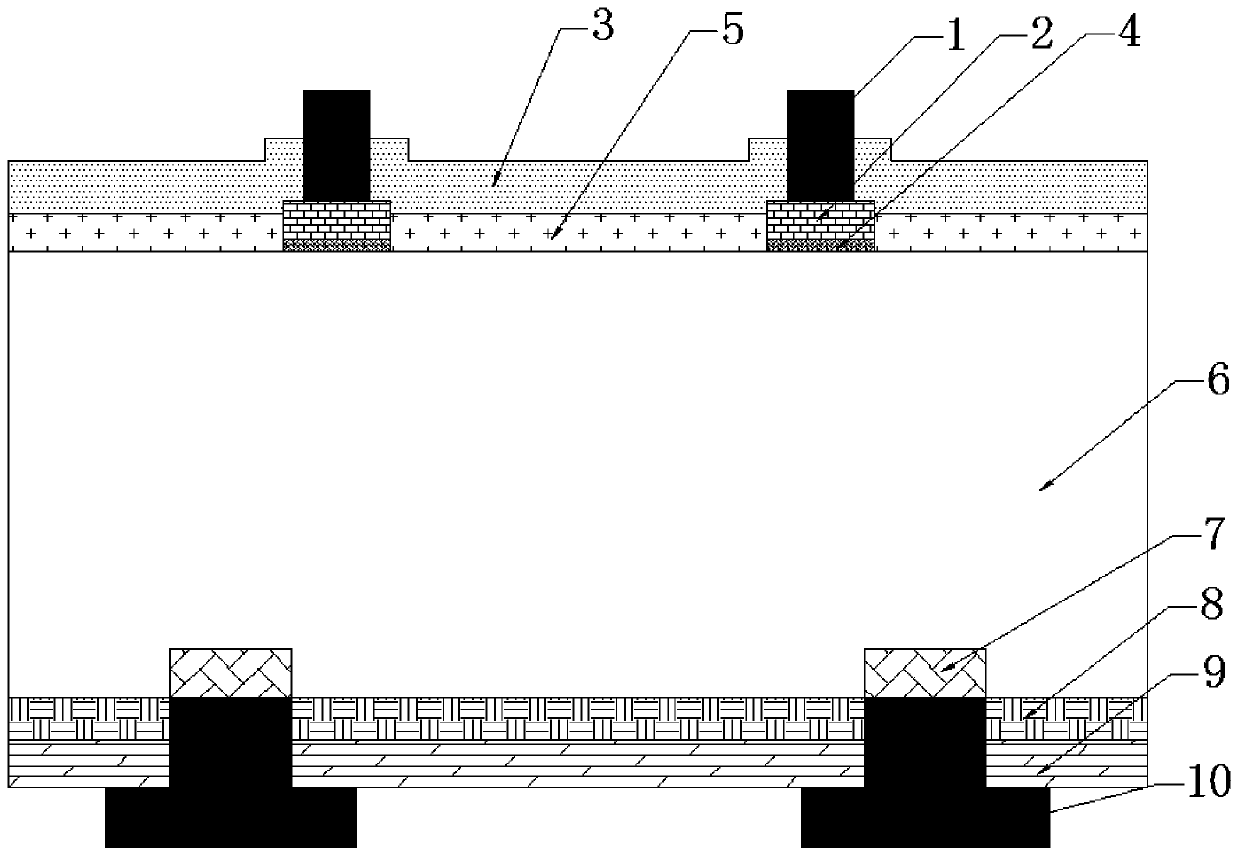

[0054] A P-type tunneling oxide passivation contact solar cell, including a front electrode, an anti-reflection layer 1, an N-type heavily doped silicon layer, a P-type silicon substrate, an Al 2 o 3 Passivation layer, anti-reflection layer two, back electrode, said anti-reflection layer one, N-type heavily doped silicon layer, P-type silicon substrate, Al 2 o 3 The passivation layer, anti-reflection layer 2, and the back electrode are stacked in sequence, and the N-type heavily doped silicon layer is also stacked with an N-type heavily doped polysilicon layer and SiO 2 layer, SiO 2 The layer is arranged in contact with the P-type silicon substrate, and the front electrode penetrates the anti-reflection layer to be in contact with the N-type heavily doped polysilicon layer.

[0055] Among them, the P-type silicon substrate is close to the Al 2 o 3 The back of the passivation layer is embedded with a P-type heavily doped silicon layer, and the back electrode passes through...

Embodiment 2

[0071] On the basis of Example 1, the preparation method for preparing a P-type tunnel oxide passivation contact solar cell in this example includes the following steps:

[0072] S1. First remove the damaged layer of the silicon wafer and then use the alkali texturing process to form a 3 μm high pyramid textured surface;

[0073] S2, using phosphorus oxychloride (POCl 3 ) High-temperature diffusion, the reaction temperature is 800°C, and the reaction time is 45 minutes, forming a P-doped N+ emitter junction on the surface of the silicon wafer, that is, an N-type heavily doped silicon layer, and forming a phosphosilicate glass (PSG) layer at the same time;

[0074] S3, cleaning the silicon wafer surface;

[0075] S31, using HF solution to remove the phosphosilicate glass (PSG) layer on the surface of the silicon wafer;

[0076] S32, using the RCA wet chemical method to clean the surface of the silicon wafer;

[0077] S4, using low-pressure chemical vapor deposition (LPCVD) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com