A kind of selective passivation contact structure of solar cell and double-sided solar cell

A solar cell and contact structure technology, applied in the field of solar cells, to achieve the effects of improving short-circuit current, good interface passivation performance, and low contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

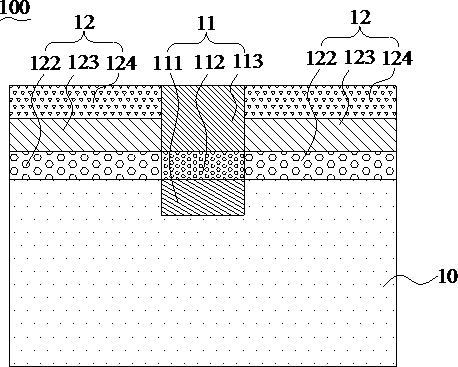

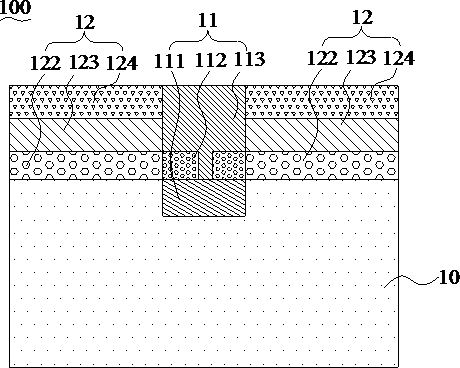

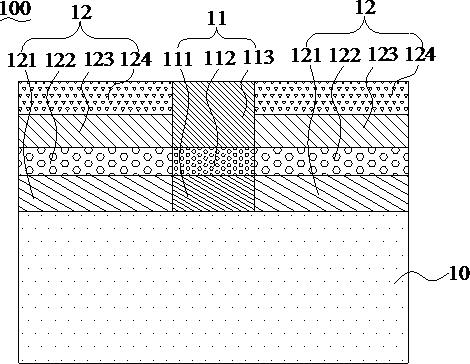

[0035] Embodiment 1 of the present application provides a selective passivation contact structure of a solar cell. For convenience of description, only parts related to the embodiment of the present application are shown.

[0036] see figure 1 The selective passivation contact structure 100 of the solar cell provided by the embodiment of the present application includes: first passivation contact regions 11 and second passivation contact regions 12 arranged alternately; The first doped layer 111, the first passivation layer 112 and the second doped layer 113 on the silicon substrate 10; the second passivation contact region 12 includes the second passivation layer stacked on the silicon substrate 10 in sequence 122, the third doped layer 123 and the third passivation layer 124; the thickness of the second doped layer 113 is greater than the thickness of the third doped layer 123, the doping of the second doped layer 113 and the third doped layer 123 same polarity.

[0037] ...

Embodiment 2

[0078] see Figure 5 , Embodiment 2 of the present application also provides a double-sided solar cell 1000, the double-sided solar cell 1000 includes a silicon substrate 10, the selective passivation contact structure 100 of Embodiment 1, and a first conductive layer 30, the selective passivation The contact structure 100 is disposed on one side of the silicon substrate 10 , and the second doped layer 113 is connected to the first conductive layer 30 .

[0079] In the double-sided solar cell 1000 of the second embodiment of the present application, since the thickness of the third doped layer 123 is small, the parasitic absorption of the second passivation contact region 12 can be reduced and the short-circuit current can be increased. At the same time, since the second doped layer 113 is thicker, it can prevent the first conductive layer 30 from burning through the second doped layer 113 and increase the open circuit voltage. At the same time, it can have excellent interfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com