TCO (transparent conductive oxide) conducting film plating device and plating process of SHJ (silicon heterojunction) solar battery

A solar cell and coating device technology, which is applied in metal material coating process, circuit, photovoltaic power generation, etc., can solve obstacles to the commercialization and application of high-efficiency SHJ solar cells, complicated equipment structure and process, and constraints on solar cell manufacturing enterprises Problems such as equipment selection and cost control, to achieve the effect of wide application prospects and economic value, high stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

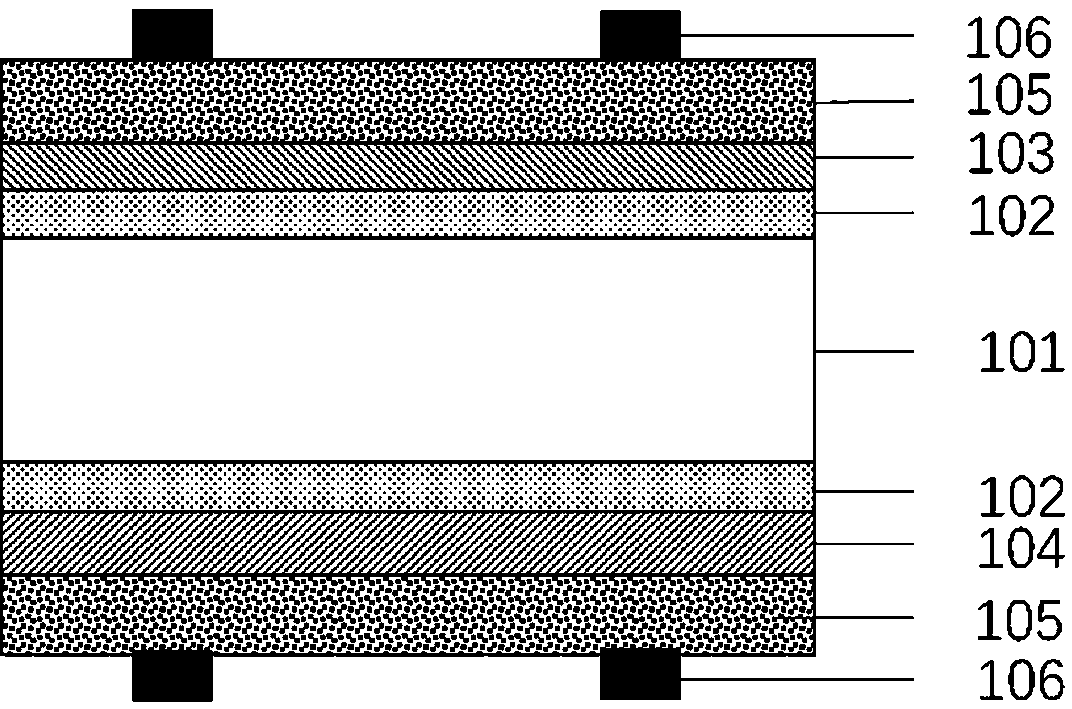

[0026] Such as figure 1 Shown is the SHJ solar cell in the prior art. During manufacture, the solar cell is based on n-type single crystal silicon wafer 101, firstly surface textured and chemically cleaned to form a clean pyramidal light-limiting structure; then plasma chemical vapor deposition (PECVD), metal Thermal catalytic chemical vapor deposition (Cat-CVD), hot wire chemical vapor deposition (Hot-wire CVD) and other methods deposit intrinsic silicon-based film 102 and n-type doped silicon-based film 103 on the front surface of silicon wafer 101. Deposit the intrinsic silicon-based film 102 and the p-type doped silicon-based film 104 stacked on the back; then deposit oxide transparent conductive film on the stacked n-type doped silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com