Light trapping structure of high-efficiency solar battery and manufacturing method thereof

A technology of solar cells and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as inability to achieve light trapping effects, lack of light field and photogenerated carrier management, and achieve improved quantum efficiency and efficiency The effect of improvement and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

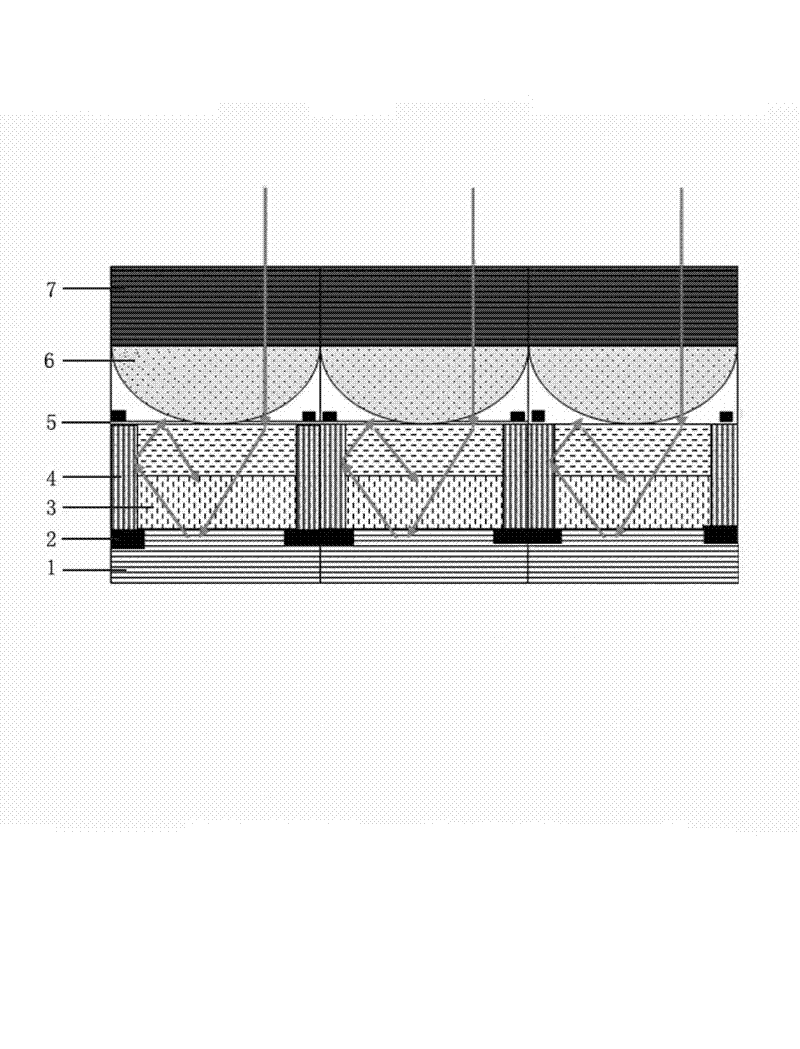

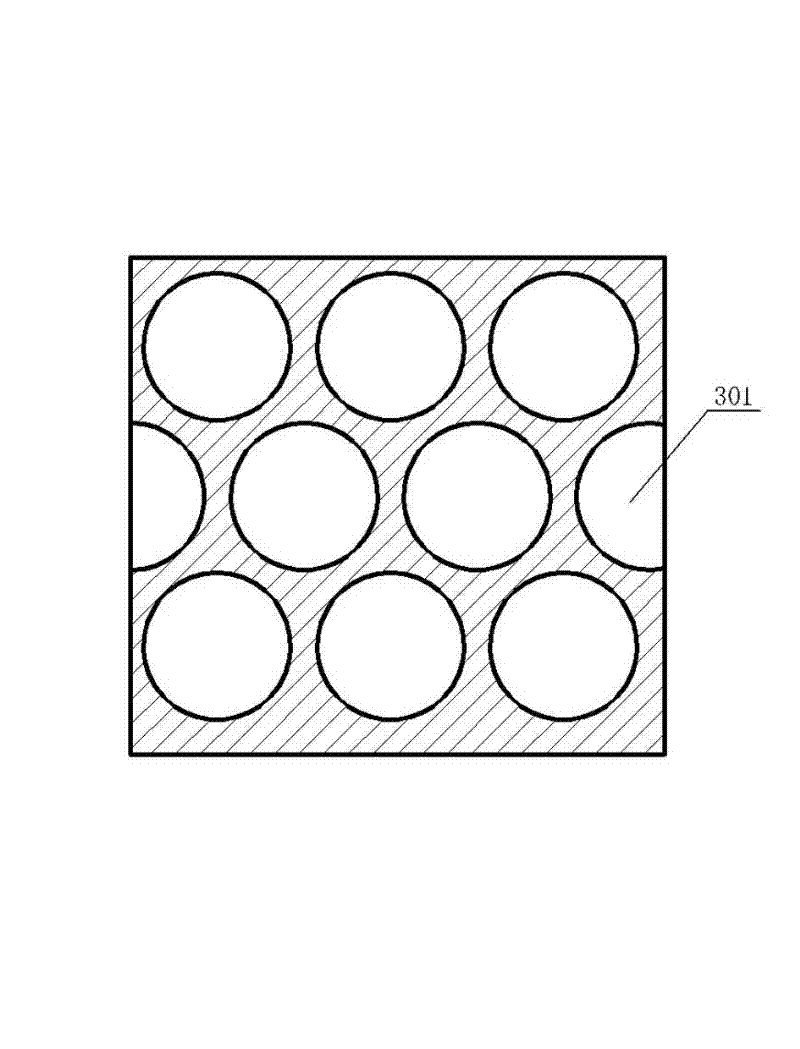

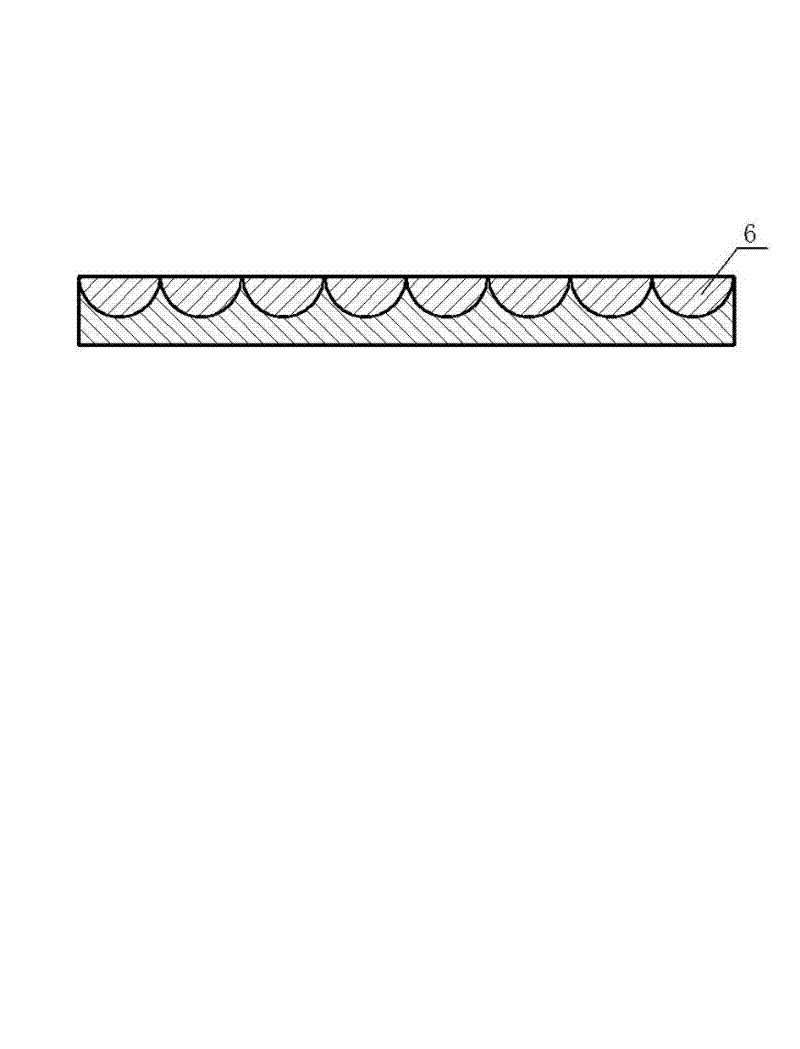

[0040] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the high-efficiency solar cell light trapping structure includes a solar cell diffusion sheet 3, an annular two-dimensional photonic crystal 4 is arranged on the solar cell diffusion sheet 3, and a two-dimensional photonic crystal full reflection mirror is formed through the complete band gap of the two-dimensional photonic crystal. Utilize the two-dimensional photonic crystal total reflection mirror to divide a plurality of micro-regions 301 on the solar cell diffusion sheet 3, and the diameter of the micro-regions 301 is 1 time of the minority carrier diffusion length of the solar cell diffusion sheet 3. Each micro-region 301 is in the form of a triangular lattice array, and buried gate electrodes (that is, upper electrode 5 and lower electrode 2 ) are provided at the edges of the corresponding micro-regions 301 on the front and back of the substrate 3, and are realized through the upper electrode 5 and...

Embodiment 2

[0049] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the high-efficiency solar cell light trapping structure includes a solar cell diffusion sheet 3, an annular two-dimensional photonic crystal 4 is arranged on the solar cell diffusion sheet 3, and a two-dimensional photonic crystal full reflection mirror is formed through the complete band gap of the two-dimensional photonic crystal. A two-dimensional photonic crystal total reflection mirror is used to divide a plurality of micro-regions 301 on the solar cell diffusion sheet 3, the plurality of micro-regions 301 are in the form of a triangular lattice array, and the diameter of the micro-regions 301 is twice the minority carrier diffusion length of the solar cell diffusion sheet 3 , in this example, the micro-area 301 has a diameter of 500 mm, and a buried gate electrode (that is, an upper electrode 5 and a lower electrode 2) is provided on the front and back sides of the substrate 3 corresponding to the e...

Embodiment 3

[0058] Such as figure 1 , figure 2 , image 3 and Figure 5 As shown, the high-efficiency solar cell light trapping structure includes a solar cell diffusion sheet 3, an annular two-dimensional photonic crystal 4 is arranged on the solar cell diffusion sheet 3, and a two-dimensional photonic crystal full reflection mirror is formed through the complete band gap of the two-dimensional photonic crystal. A two-dimensional photonic crystal total reflection mirror is used to divide a plurality of micro-regions 301 on the solar cell diffusion sheet 3, the plurality of micro-regions 301 are in the form of a triangular lattice array, and the diameter of the micro-regions 301 is 1.5 times the minority carrier diffusion length of the solar cell diffusion sheet 3 , in this example, the diameter of the micro-region 301 is 300 mm, and a buried gate electrode (ie, the upper electrode 5 and the lower electrode 2) is provided on the front and back of the substrate 3 corresponding to the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com