Organic dye compound and dye-sensitized solar cell comprising the same

A technology for solar cells and dye sensitization, applied in the field of dye-sensitized solar cells, can solve the problems of poor metal oxide adsorption, low light conversion rate, chemical instability, etc., to improve electron mobility and prevent open circuit voltage. Too low, the effect of maximizing the photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0094] (2) Production example of Sub3: 10-(4-{2-[2-(2-methoxy-ethoxy)-ethoxy]-ethoxy}-phenyl)-3,7-

[0095]

[0096]

[0097] 3,7-dibromo-10-(4-{2-[2-(2-methoxy-ethoxy)-ethoxy]-ethoxy}-phenyl)-10H-phenothiazine (0.95g, 2.1mmol), tributyl-thiophen-2 base-stannane (2.03g, 5.4mmol) and bis(triphenylphosphine)palladium dichloride (PdCl , (PPh 3 ) 2 , 0.1 g, 0.13 mmol) was dissolved in 50 mL of dry tetrahydrofuran (THF), refluxed at 70° C., and stirred for 24 hours. After reacting weft, in water and chloroform (CHCl 3 ) in a 1:1 mixed solvent for separation and purification tests. After separating the organic layer through the separation and purification test process by the extraction method, the solvent was removed under reduced pressure. After removal of the solvent, silica gel column chromatography (chloroform: ethane, 1:3) was used to obtain a yellow solid product (0.759, 81.5%)

[0098] The chemical characteristics of the compound obtained are as follows:

[00...

Embodiment 15

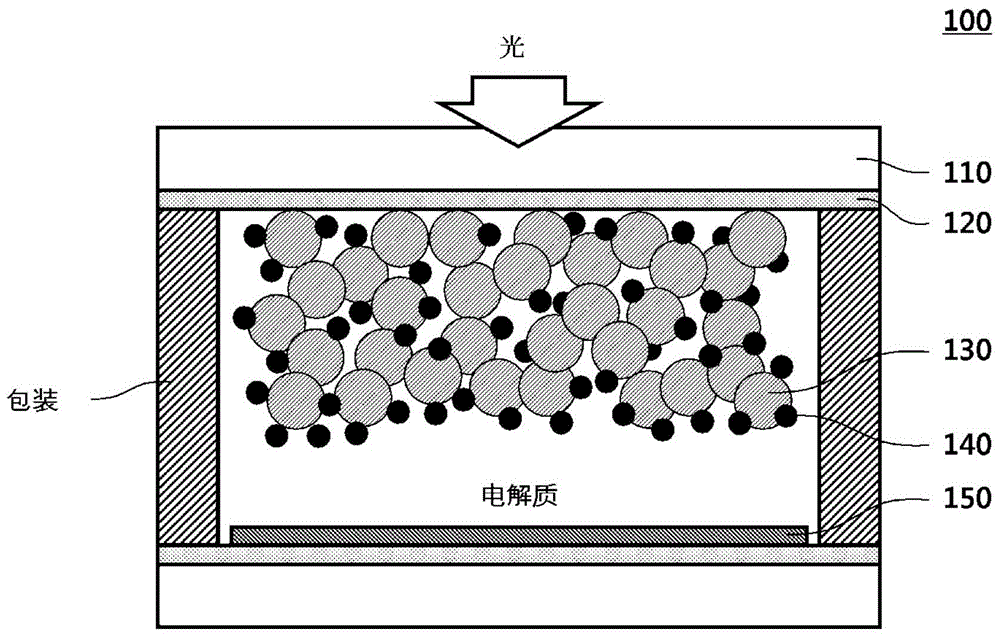

[0141] [Example 1] to [Example 15]: Manufacture of dye-sensitized solar cell

[0142] First, the conductive glass substrate (FTO; TEC8, Pilkington, 8Ωcm 2 , Thicknessof2.3mm) into ethanol, after cleaning, prepare commercial titanium dioxide (TiO 2 ) slurry (20nm, solarnonix), apply the prepared titanium dioxide slurry on the pre-cleaned glass substrate with a scraper, and burn it at 500°C for 30 minutes. The thickness of the fired titanium dioxide slurry is determined by Alpha-step IQ step meter (KLA Tencor) to measure. In order to use another titanium dioxide slurry as the scattering layer, the above-mentioned scattering layer was recoated with particles having a size of 250 nm, and then fired at 500° C. for 30 minutes. At 70°C, put the prepared titanium dioxide film into 0.04M titanium tetrachloride (TiCl 4 ) solution, soak for 30 minutes.

[0143] Next, to achieve dye adsorption, the annealed titanium dioxide electrode was placed in a dye solution (0.3 mM) containing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com