Crystalline silicon solar cell and manufacture method thereof

A technology of solar cells and manufacturing methods, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced electrical performance, reduced battery performance, reduced electrical performance, etc., to reduce contact area, reduce recombination loss, and reduce defect recombination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

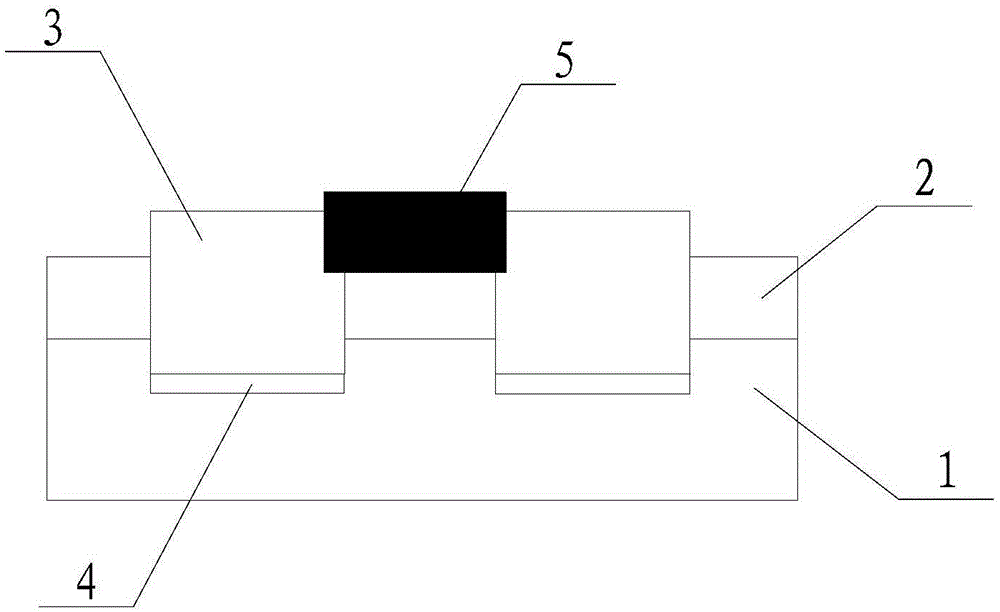

[0026] Such as figure 1 The crystalline silicon solar cell shown mainly includes an N-type silicon wafer substrate 1 , an antireflection film 2 , a first grid line 3 , a doped layer 4 and a second grid line 5 .

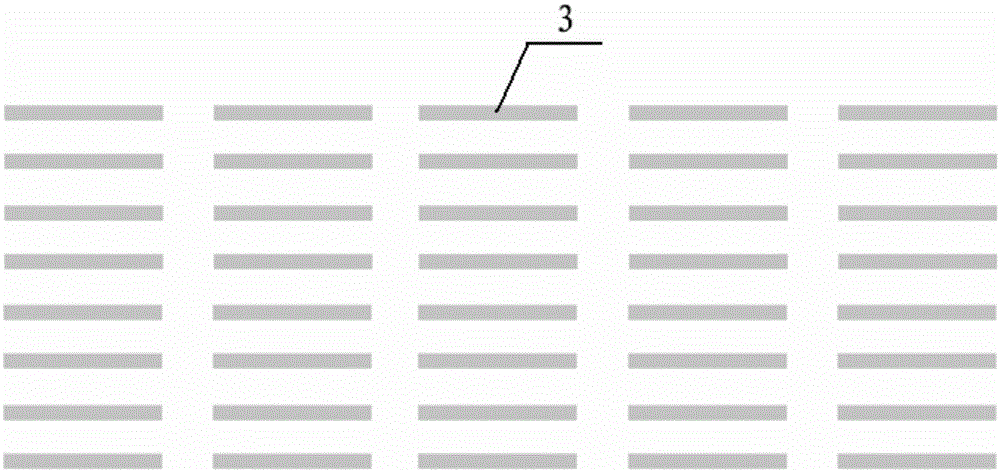

[0027] Wherein, the anti-reflection film 2 is formed on any surface of the N-type silicon wafer substrate 1 . There are multiple first grid lines 3, such as figure 2 As shown, they are arranged in multiple columns parallel to each other and arranged at intervals, and the corresponding first gate lines 3 in each column are on the same straight line; one end (bottom) of the first gate lines 3 is embedded in the N-type silicon substrate 1, the other end (upper part) extends beyond (or higher than) the anti-reflection film 2. The doped layer 4 is correspondingly formed on the bottom of the first gate line 3 and integrally formed on the surface of the N-type silicon substrate 1. The doped layer 4 is preferably a P heavily doped layer, so that the N-type silicon substrat...

Embodiment 2

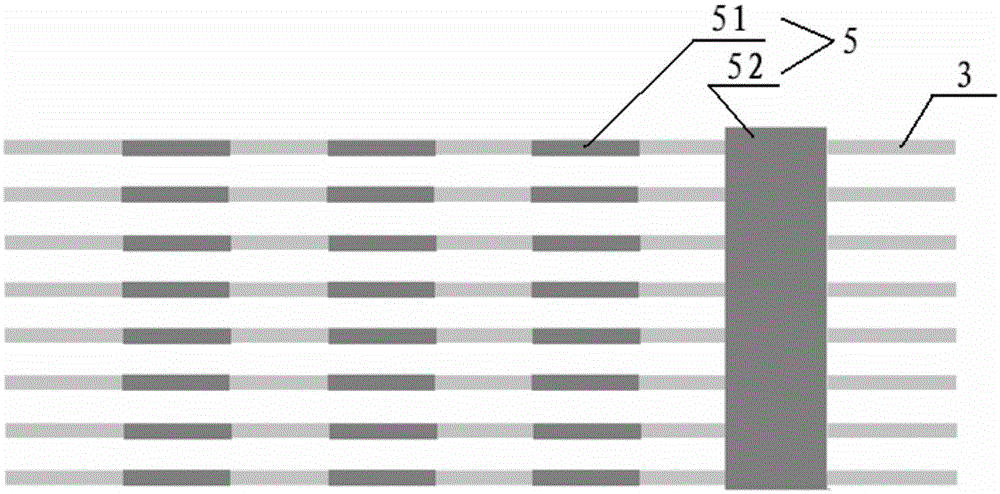

[0030] Such as Figure 4 The overall structure of the crystalline silicon solar cell shown is basically the same as that of the crystalline silicon solar cell in Embodiment 1, the difference is that the connecting grid lines 51 cover multiple first grid lines 3 on the same straight line, instead of only It is to connect opposite ends of two adjacent first grid lines 3 . The main gate line 52 covers the plurality of first gate lines 3 or the plurality of connecting gate lines 51 , and its extension direction is perpendicular to the extension direction of the corresponding first gate lines 3 in each column.

Embodiment 3

[0032] This embodiment provides a method for manufacturing a crystalline silicon solar cell in Embodiment 1, which includes the following steps:

[0033] (a) Form an antireflection film 2 on any surface of an N-type silicon wafer substrate 1. For the formation method, please refer to CN201510020649.4, specifically: adopt the lamination passivation method of aluminum oxide and silicon nitride, aluminum oxide It plays a passivation role, and silicon nitride plays the role of protecting and adjusting optical parameters and reducing reflectivity; the passivation anti-reflection film formed by aluminum oxide and silicon nitride can be produced by PECVD or ALD method, and the nitriding film can be produced by PECVD method Silicon passivation anti-reflection coating;

[0034] (b) Print the first paste corresponding to the first grid line 3 on the anti-reflection film 2, and dry it; the printing technology includes but not limited to screen printing, electroplating and 3D printing, et...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com